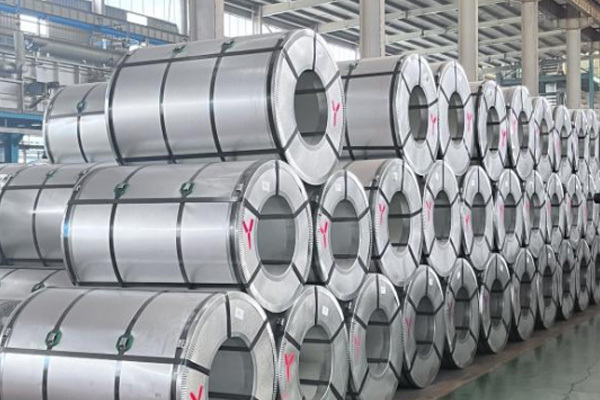

Aluminum Coil Stock and Coil Aluminum for Industrial Use

Aluminum coil stock is a simple and useful metal material. It is made by rolling aluminum sheet into long coils. This shape is easy to store, easy to ship, and easy to use. Because of this, coil aluminum is widely used in many industries.

In most cases, the coil is typically produced by rolling flat aluminum step by step. This includes hot rolling and cold working. The result is an aluminum sheet in coil form with even thickness and a clean surface. Since aluminum coil can be produced in long lengths, it helps save material and lowers production cost.

Why Coil Aluminum Is Easy to Work With

A key reason people choose aluminum coil stock is its strength to weight ratio. Aluminum is light, but it can still be strong. This makes coil aluminum stock a good choice for applications requiring strength without extra weight.

Another major benefit is corrosion resistance formability. Aluminum forms a natural protective layer on its surface. This layer helps stop rust and damage. At the same time, the metal stays easy to bend and shape. This mix of strength and corrosion resistance works well for long-term use.

Aluminum sheet supplied in coil form is also ideal for cold working. It can be bent, cut, punched, or roll-formed with little risk of cracking. This helps improve speed and efficiency in production.

Aluminum Grades Explained Simply

Aluminum coil stock is available in a wide range of aluminum grades. Each grade has a clear purpose. Some grades are soft and easy to form. Others are made for high strength.

Pure aluminum is often used for applications requiring good corrosion resistance and smooth surfaces. It is easy to shape and works well in basic products. When higher strength is needed, alloy materials are used. These offer better load performance and longer service life.

Some aluminum grades are heat treatable. This means heat is used to increase strength. These grades are common in parts that need extra durability. Non-heat-treatable grades are chosen when easy forming and corrosion resistance are more important.

Production Quality and Options

Aluminum coil can be produced in a wide range of thicknesses and widths. This allows buyers to choose the right size for their project. Surface options include mill finish, coated, and painted aluminum sheet. These finishes improve appearance and surface protection.

High quality control is important in production. Thickness and surface condition are checked carefully. This helps ensure stable performance during later processing.

Aluminum is also easy to recycle. Aluminum coil stock can be reused many times without losing quality. This supports sustainable industry aluminum use.

Common Applications

Because it is light, strong, and easy to form, aluminum coil stock is used in many areas:

Construction: Roofing, wall panels, ceilings, and mobile homes

Transportation: Vehicle panels and light structures

Food processing: Clean containers and protective covers

Industrial equipment: Parts exposed to moisture or chemicals

Home appliances: Refrigerators, air conditioners, and trims

These industries value aluminum sheet coils for both function and appearance.

Why Buyers Prefer Coil Aluminum Stock

Coil aluminum stock is often better than cut sheets. It allows users to cut only what they need. This reduces waste and saves money.

Aluminum sheet coils also offer consistent quality. Thickness is even, and surfaces are smooth. This is important for automatic machines and mass production. Many applications requiring stable quality depend on coil aluminum materials.

Because aluminum coil stock comes in many options, buyers can choose the right aluminum grades based on strength, corrosion resistance, and formability.

Industry Aluminum Benefits

For industry aluminum users, aluminum coil stock offers long service life and low upkeep. Its light weight makes transport and installation easier. Its high strength helps ensure safe use.

From pure aluminum to high strength, heat treatable alloys, aluminum sheet in coil form fits modern production needs. It supports simple processing, steady quality, and efficient output.

Conclusion

Aluminum coil, aluminum coil stock, coil aluminum, and coil aluminum stock are key materials in modern industry aluminum markets. Made from aluminum sheet and supplied in continuous coils, these products offer high quality, good cold working performance, and strong corrosion resistance. With many aluminum grades available, aluminum coil stock meets the needs of applications requiring strength, durability, and easy processing.