What Is a Steel Coil and What Is It Used For?

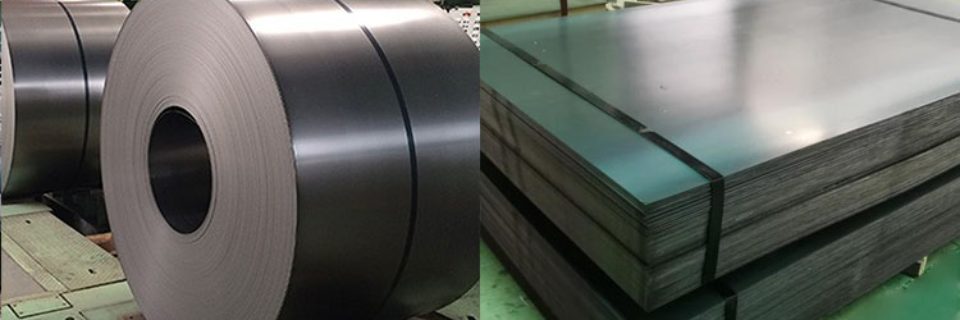

A steel coil is a flat steel strip that has been shaped through rolling and wound into a circular form. This coiled steel format makes handling, storage, and transportation much easier. Because it supports fast and continuous processing, this rolled steel material is widely used across construction, manufacturing, automotive production, and consumer goods industries.

Coiled steel products are valued for being cost effective and flexible. They allow factories to run long production lines with less waste and lower labor costs, making them a key raw material in modern industry.

Understanding Coiled Steel Products

In simple terms, this type of rolled steel is made by reducing steel slabs or billets into long strips with a specific width and thickness. Once the target size is reached, the strip is wound into a coil. This compact shape saves space and supports continuously rolling in later processing stages.

These steel products are usually semi-finished materials. They are later cut into sheets, slit into narrower strips, or formed into pipes, profiles, and other components. Different grades and finishes are available to meet various application requirements, from high strength to smooth surface quality.

Hot Rolling and Cold Rolling Made Easy

The properties of steel coils depend mainly on whether they are produced by hot rolling or cold rolling. These two methods differ in temperature, cost, and final performance.

Hot Rolling

Hot rolling is carried out at high temperatures, above the steel’s recrystallization point. At these high temperatures, steel becomes soft and easy to shape. The rolling process can reduce thickness quickly, making it suitable for large-scale production.

Hot rolled steel coils are known for their strength, toughness, and good weldability. Their surface finish is usually rougher, and size accuracy is lower compared to cold rolled products. However, fewer processing steps make them more cost effective. They are commonly used in construction, steel structures, bridges, and heavy machinery.

Cold Rolling

Cold rolling is done at room temperature, starting from hot rolled material. The steel passes through rollers again to improve thickness accuracy and surface smoothness.

This process increases strength and hardness but also creates internal stresses due to work hardening. These internal stresses can affect flexibility, so some products require further treatment. Cold rolled steel coils are widely used in automotive parts, home appliances, office furniture, and other applications where appearance and precision matter.

The Rolling Process and Continuous Production

The rolling process is the core of steel coil manufacturing. Steel passes through several rolling stands until it reaches the required thickness. Modern mills use continuously rolling systems, which allow the steel strip to move through the line without stopping.

Continuously rolling improves thickness consistency and mechanical stability across the entire coil. It also reduces production time and energy use. This efficiency helps keep coiled steel products affordable while maintaining stable quality.

Main Types of Steel Coils

There are several common categories of steel coils, each designed for different uses:

Produced at high temperatures. Strong, durable, and widely used in construction and industrial projects.

Made with additional rolling at room temperature. Offer smooth surfaces and precise dimensions.

Covered with a zinc layer to prevent rusting. Commonly used for roofing, fencing, and steel pipes.

Coated with aluminum-zinc for improved corrosion resistance in outdoor environments.

Pre-painted products used where appearance and durability are both important.

Each option is chosen based on strength needs, surface requirements, and exposure conditions.

Applications Across Industries

Rolled steel coils are used in many sectors because they fit well into automated and continuous production lines.

In the construction industry, hot rolled materials are used for beams, columns, pipes, and structural parts. Coated coils are popular for roofing sheets and wall panels because they resist weather and corrosion.

In the automotive industry, cold rolled products are used to manufacture body panels, frames, and safety components. Their stable thickness helps improve product quality and performance.

In manufacturing, coiled steel is fed directly into machines for cutting, stamping, and forming. This reduces waste and speeds up production.

For consumer goods, steel coils are used in appliances, cabinets, shelving, and furniture. Color coated products add visual appeal and long service life.

Why Coiled Steel Is So Widely Used

One major advantage of using steel in coil form is flexibility. A single coil can be processed into many different finished products. This helps manufacturers manage inventory and respond quickly to market demand.

Another benefit is consistency. Advanced rolling technology ensures stable width and thickness, which is essential for automated production lines. Transportation and storage are also easier due to the compact coil shape.

Hot rolled steel coils, in particular, offer a strong and cost effective solution for large projects that do not require perfect surface finish.

Choosing the Right Steel Coil Material

Selecting the right rolled steel product depends on how it will be used. Outdoor projects usually need corrosion-resistant coatings. Precision parts often require cold rolled material with tight tolerances.

Buyers should consider strength, thickness, surface finish, and budget. Understanding hot rolling and cold rolling differences makes the selection process much clearer. Working with reliable suppliers also helps ensure stable quality and timely delivery.

Conclusion

Steel coils are a basic but essential material in modern industry. Produced through hot rolling and cold rolling, they offer strength, flexibility, and high production efficiency. With continuously rolling processes and wide application potential, coiled steel products support construction, automotive manufacturing, and consumer goods production worldwide.