Understanding Galvalume Steel Coil: Properties, Applications, and Production Process

The production process of Galvalume steel coil begins with cold-rolled or hot-rolled steel sheets, which are then cleaned and pre-treated to remove any contaminants. The sheets are subsequently coated with a liquid mixture of aluminum and zinc, often through a continuous hot-dip process. This method not only enhances the adhesion of the coating to the steel but also creates a smoother, more uniform surface. After coating, the steel coils are cooled and prepared for further processing, such as slitting, shearing, or forming.

One of the most notable applications of Galvalume steel coil is in the construction industry. Its excellent corrosion resistance makes it particularly suitable for roofing, siding, and other exterior applications where exposure to the elements is a concern. Galvalume is often used in residential and commercial buildings due to its longevity and minimal maintenance requirements. Additionally, the aesthetic appeal of Galvalume-coated materials, which can be painted or left in their natural state, further enhances its popularity among architects and builders.

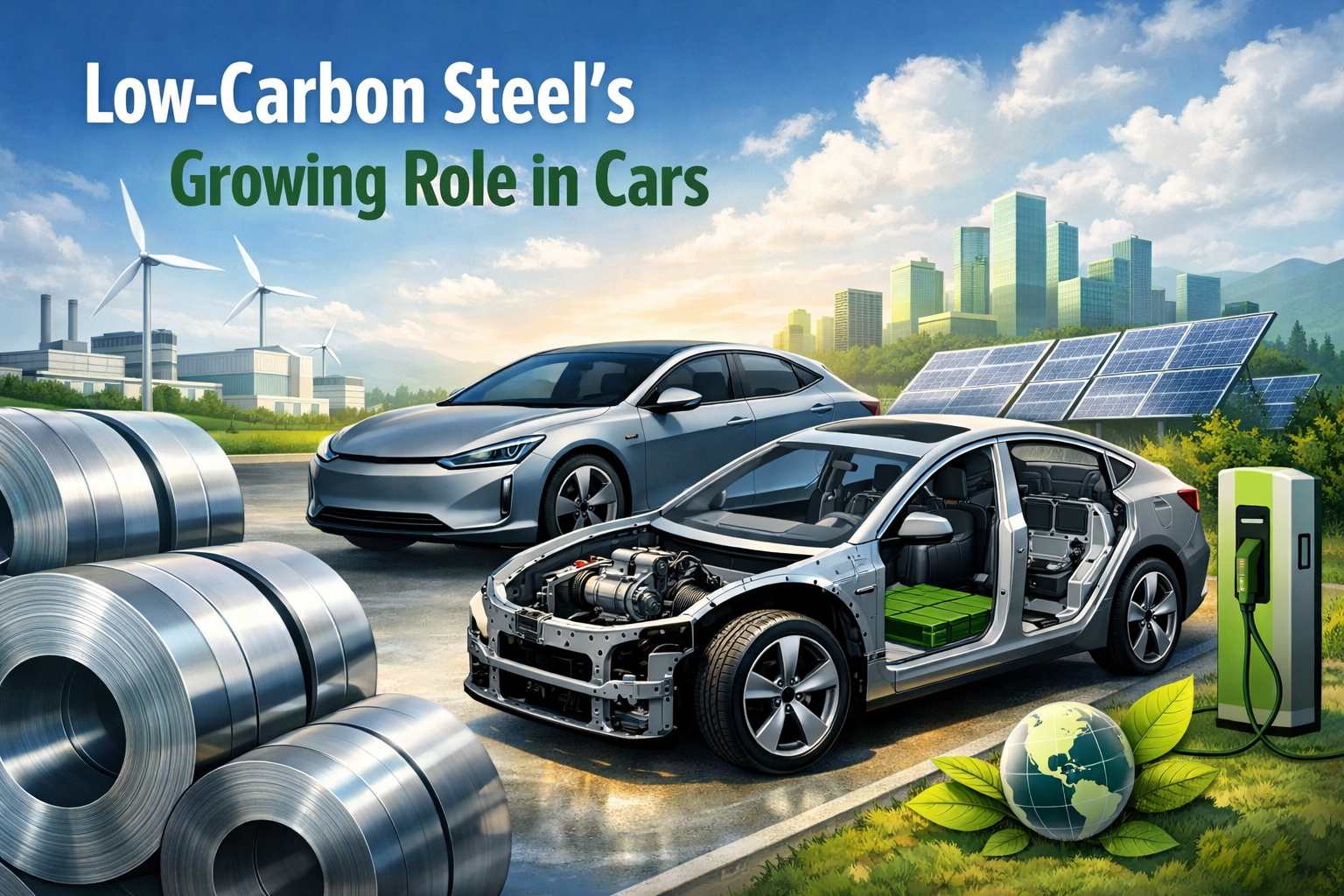

Another significant application of Galvalume steel coil is in the manufacturing of appliances. The automotive and electronics industries also utilize this material because of its lightweight properties combined with excellent durability. Galvalume is used in the production of components such as car bodies, electrical enclosures, and HVAC systems, where resistance to corrosion is paramount.

In summary, Galvalume steel coil is a remarkable material that combines the strength of steel with the protective qualities of aluminum and zinc. Its unique production process allows for a high-quality finish that is both durable and attractive. With its diverse applications across various industries, from construction to manufacturing, Galvalume steel coil continues to be an essential material in modern engineering and architecture. As industries look for materials that balance performance with longevity, Galvalume stands out as a trusted choice for many applications.