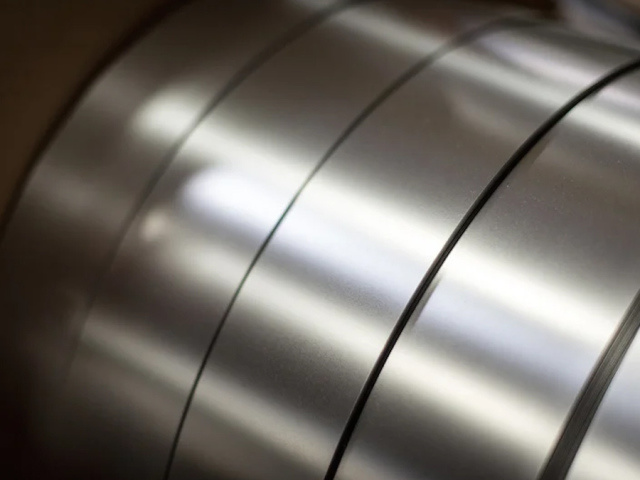

Cold rolled steel coil

WhatsApp / Tel / Wechat

Still deciding? Get samples first, Contact US !

View similar products

- Product Description

-

what is a Cold rolled steel coil

Cold-rolled steel coil (CR Coil) is a high-quality flat steel product that is manufactured from cold-rolled coil at room temperature with excellent surface quality and mechanical properties. CR coils have a very smooth surface (suitable for painting/coating), tight dimensional tolerances (±0.02mm), and work hardening for enhanced strength, providing excellent performance in precision applications such as automotive body panels, appliances, electronics, and building components. Available in (SPCC, DC01, ASTM A1008) grades and finishes (oiled, passivated), it offers better formability and maintains higher hardness and precision than hot-rolled alternatives.

Cold rolled steel coil Specifications

Thickness

0.4-3.2mm

Width

600-1500mm

Length

2000-3000m

*Special specifications can be customized

Time of delivery:15days

Material

Q195A-Q235A、Q195AF-Q235AF、Q295A(B)-Q345 A(B);SPCC、SPCD、SPCE、ST12-15;DC01-06

Cold rolled steel coil Advantages

1. Excellent surface: zero defects in finishing, cleanliness reaches Sa2.5 level, smoothness Ra0.3-1.5μm, and can be processed to super mirror effect.

2. Easy to process: elongation 50%, suitable for precision processing such as stamping, bending, laser welding, etc.

3. Dimensional accuracy: thickness tolerance ±0.01mm, width ±0.3mm, straightness ≤1.5mm/m.

4. Wide range of uses: covering thickness of 0.15-3.0mm, meeting the needs of automobiles, electronics, home appliances and other fields.

5. High-end substrate: It is an ideal substrate for spraying and electroplating, promoting the improvement of manufacturing quality.

Cold rolled steel coil Application

1. Automobile Manufacturing: high-end automotive panels, body structures, and chassis components

2. Electrical Products: housings for precision electronic devices such as laptops and smartphones

3. Locomotives: Lightweight structural components for high-speed rail and subway cars

4. Aviation: aircraft interior parts and some non-load-bearing structural parts

5. Precision Instruments: Manufacturing of high-precision equipment such as medical equipment and optical instruments

6. Canned Food: canned food, beverage cans, etc.

Production Process

Cold rolled steel coil are made of hot rolled coils and are rolled at room temperature below the recrystallization temperature. They include plates and coils. The ones delivered in sheets are called steel plates, also called box plates or flat plates; the ones delivered in long lengths in coils are called steel strips, also called coils. It is rolling under recrystallization, but it is generally understood as rolling using room temperature rolled materials. Aluminum cold rolling is divided into plate rolling and foil rolling. Plates with a thickness of 0.15~ or more are called plates, and foils with a thickness of 0.15~ or less are called foils. Europe and the United States mostly use 3 to 6 continuous rolling mills as cold rolling equipment.

Raw materials → weighing, measuring width and diameter → uncoiling → cutting ends and tails → welding, punching, punching → pickling → rinsing, drying → circular shears → rolling → curling → shearing and splitting → weighing and bundling

Cold rolled steel coil mechanical properties

Grade Yield strength Mpa

Tensile strength Mpa

Elongation %

Plastic strain ratio Strain hardening index DC01

140~280

270~410

≥28

DC02

140~240

270~370

≥34

≥1.4

DC03

120~210

270~350

≥38

≥1.8

≥0.18

DC04

120~180

270~330

≥40

≥2.0

≥0.20

SPCC

130~300

270~410

SPCD

120~240

270~370

≥1.3

SPCE

120~210

270~350

≥1.8

≥0.18

Product Standards

GB/T 708 EN 10130:1998 JISG3141:2005

FAQ

Why is cold rolled steel more expensive?

The main reason why cold-rolled steel is more expensive is its fine machining and superior properties: compared to hot-rolled steel, cold-rolled steel has higher strength (work hardening), more precise dimensions (±0.02mm) and a smoother surface due to additional processes such as room temperature rolling and annealing. Although the average price is 20-50% higher, it eliminates the cost of subsequent processing and meets the needs of industries with strict requirements for precision and surface.

Cold rolled steel coil

WhatsApp / Tel / Wechat

Contact us via email

Still deciding? Get samples first, Contact US !

Products Category

Tag list

Steel coil

Low Carbon Steel Cold Rolled Coil

Cold rolled coil

Smooth surface steel coil

Inquire Now

Note: Please leave your email address, our professionals will contact you as soon as possible!

Related Products