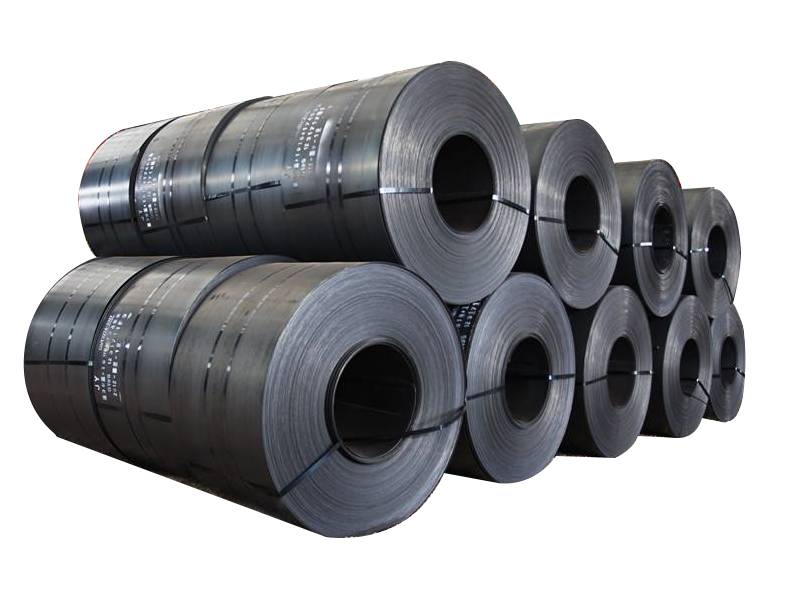

Hot rolled steel coil manufacturers

WhatsApp / Tel / Wechat

Still deciding? Get samples first, Contact US !

View similar products

- Product Description

-

HRC Specifications

Thickness

0.8-16mm

Width

910-1600mm

Inner diameter

570mm

Roll weight

5-25t

Main Materials

The main materials used for hot-rolled coil steel are Q195, Q235B, Q345B, Q355B, Q355BH, Q355C, Q355D, Q345A, Q345E, SPHC, SPHE, SPHD, SAE1006

Time of delivery:15days

Hot Rolled Coil Steel Description

Hot-rolled coil (HRC) steel is a steel made by heating slabs or billets to their recrystallization temperature, typically over 1,000°C, and then rolling them into thin sheets or coils. The use of high-temperature processes makes steel easier and faster to form, with excellent mechanical properties, good surface finish, and cost-effectiveness in practical applications.

Advantages of hot rolled steel coil

1. High strength Hot-rolled steel coils offer exceptional strength, meeting the demands of load-bearing structures and high-stress applications in industries such as construction, automotive, and heavy machinery.

2. Good toughness Excellent toughness, able to withstand shock and dynamic loads, providing durability and reliability even in harsh environments.

3. High dimensional accuracy Advanced manufacturing processes ensure dimensional accuracy, enabling tight tolerances and consistent performance in critical applications.

4. Good board shape Excellent flatness and shape stability, reducing the need for additional straightening or flattening during manufacturing.

5. Smooth surface quality Hot rolled steel coils have a uniform, smooth surface that minimizes defects and improves paint adhesion or coating performance.

Hot rolled coil steel uses

1. Ships

Hot rolled steel coils provide high strength and corrosion resistance in hull, deck and marine structure applications.

2. Car

Used in vehicle chassis, frames and body panels, it provides durability while maintaining lightweight efficiency.

3. Bridge

Its excellent load-bearing capacity and fatigue resistance make it the main material for highway and railway bridge construction.

4. Buildings

Its high strength and weldability enable it to meet the demands of structural frames, beams and columns in high-rise buildings and industrial facilities.

5. Machinery

Durable gears, axles and components for heavy equipment.

6. Pressure vessels

Boilers, tanks and pipes.

Hot rolled steel coil Production process

The production process for hot-rolled steel coils is as follows: after heating the slab to 1200°C, it undergoes rough rolling to remove phosphorus, edge rolling with vertical rollers, and rolling into an intermediate bar in the roughing mill. The bar then undergoes fly shearing to separate the head and tail. It then undergoes finishing rolling to remove phosphorus, followed by seven-stand finish rolling to the target thickness. After laminar cooling and temperature control, the bar is coiled into a coil by a coiler. Finally, finishing processes such as flattening and shearing are performed as needed to produce finished products such as steel plates, flat coils, or slit steel strips.

Slab out of furnace → Roughing dephosphorization box → Large vertical roller roughing mill → Hot coil box → Flying shear → Finishing dephosphorization device → Finishing vertical roller → Seven-stand finishing mill → Laminar cooling system → Downcoiler → Finishing line → Finished product

Thickness

Yield Strength

Tension strength

Elongation

>1.5-2.5

≤290Mpa

≥310Mpa

≥38

>2.5-3.0

≤290Mpa

≥300Mpa

≥38

>3.0-4.0

≤290Mpa

≥300Mpa

≥40

Hot rolled coil steel Faqs

What is HRC steel used for?

HRC (Hot Rolled Coil) steel is a versatile and cost-effective material that offers high strength, formability, and economy, and is widely used in construction and infrastructure, automotive and transportation, tube manufacturing, machinery and equipment, manufacturing and fabrication, energy, and heavy industry

What are the three types of hot rolled steel?

Hot-rolled steel can be classified into three types based on its build composition, mechanical properties, and intended application: commercial quality (CQ) hot-rolled steel, structural

How long is your delivery time?

Standard delivery takes 15-20 working days, with a fast-track 15-20 day option available for urgent orders.

Hot rolled steel coil manufacturers

WhatsApp / Tel / Wechat

Contact us via email

Still deciding? Get samples first, Contact US !

Products Category

Tag list

Low alloy hot rolled steel coil

High Carbon Steel Hot Rolled Coil

Hot Rolled Coil

High Temperature Rolled Steel Coil

Inquire Now

Note: Please leave your email address, our professionals will contact you as soon as possible!

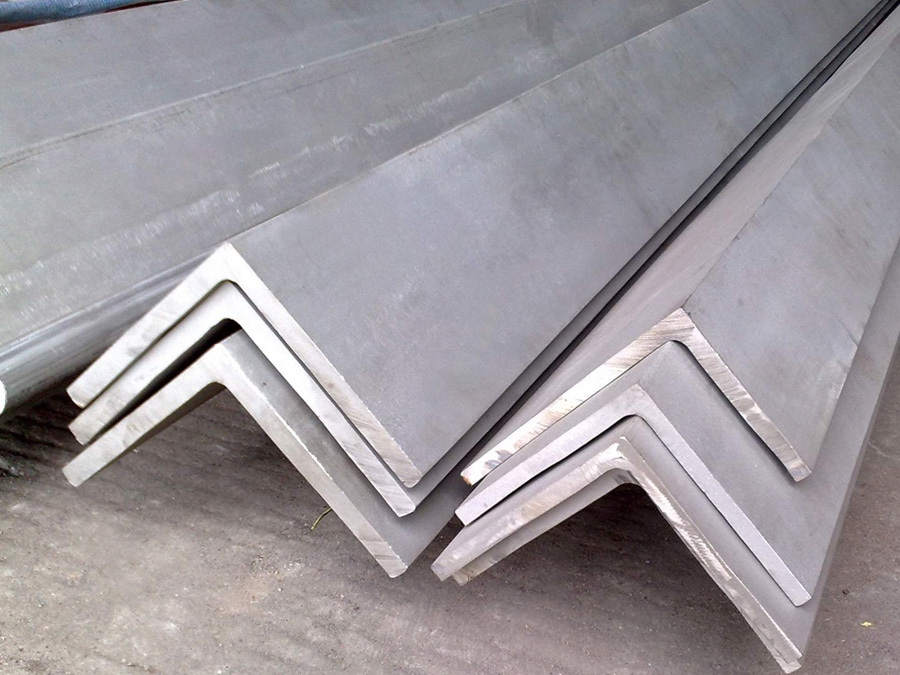

Related Products