H Beam Steel | Steel H Beams Supplier

WhatsApp / Tel / Wechat

Still deciding? Get samples first, Contact US !

- Product Description

-

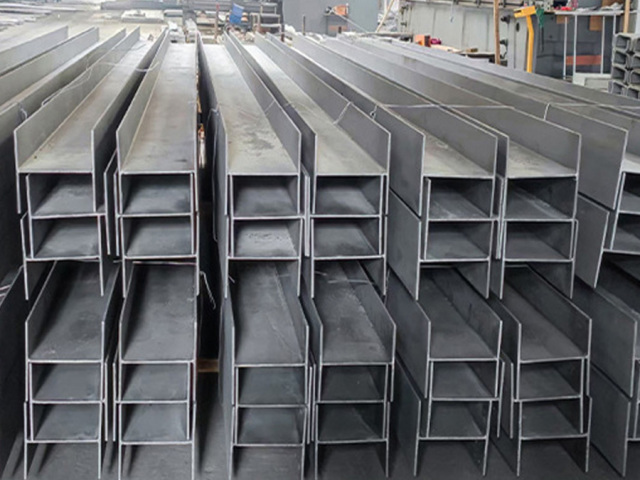

What Is H Beam Steel?

H beam steel is a structural steel section with a wide flange and uniform thickness, forming an H-shaped profile. This design allows loads to be evenly distributed, improving resistance to bending and deformation.

In international markets, this product is also commonly referred to as steel H beams, especially in large-scale building and infrastructure projects supplied by experienced manufacturers like Shineyond Group.

H Beam Steel Classification

Hot rolled H beam specifications are divided into wide flange hot rolled H-beam specifications (HW), narrow flange hot rolled H-beam specifications (HN).

H Beam Steel Product Specifications

Height (H): Generally ranges from 100mm to 900mm, with customized options available for specific project requirements.

Flange Width (B): Typically between 50mm and 300mm, suitable for different load-bearing needs.

Web Thickness (t1): Ranges from 6mm to 30mm, depending on the size and structural application of the H-beam.

Flange Thickness (t2): Usually equal to or slightly less than the web thickness, ensuring balanced strength and stability.

Section Area: Varies according to the beam’s height and thickness, ranging from tens to several hundred square centimeters, providing excellent load-carrying capacity.

Type

Model (height*width)

Cross-section size/mm

Cross-sectional area/cm²

H×B

t₁

t₂

r

HW

Wide flange

100×100

100×100

6

8

10

21.90

125×125

125×125

6.5

9

10

30.31

150×150

150×150

7

10

13

40.55

175×175

175×175

7.5

11

13

51.43

200×200

200×200

8

12

16

64.28

200×204

12

12

16

72.28

250×250

250×250

9

14

16

92.18

250×255

14

14

16

104.7

300×300

294×302

12

12

20

108.3

300×300

10

15

20

120.4

300×305

15

15

20

135.4

350×350

344×348

10

16

20

146.0

350×350

12

19

20

173.9

400×400

388×402

15

15

24

179.2

394×398

11

18

24

187.6

400×400

13

21

24

219.5

400×408

21

21

24

251.5

414×405

18

28

24

296.2

428×407

20

35

24

361.4

458×417

30

50

24

529.3

498×432

45

70

24

770.8

Type

Model (height*width)

Cross-section size/mm

Cross-sectional area/cm²

H×B

t₁

t₂

r

HM

Middle flange

150×100

148×100

6

9

13

27.25

200×150

194×150

6

9

16

39.76

250×175

244×175

7

11

16

56.24

300×200

294×200

8

12

20

73.03

350×250

340×250

9

14

20

101.5

400×300

390×300

10

16

24

136.7

450×300

440×300

11

18

24

157.4

500×300

482×300

11

15

28

146.4

488×300

11

18

28

164.4

600×300

582×300

12

17

28

174.5

588×300

12

20

28

192.5

594×302

14

23

28

222.4

Type

Model (height*width)

Cross-section size/mm

Cross-sectional area/cm²

H×B

t₁

t₂

r

HN

Narrow flange

100×50

100×50

5

7

10

12.16

125×60

125×60

6

8

10

17.01

150×75

150×75

5

7

10

18.16

175×90

175×90

5

8

10

23.21

200×100

198×99

4.5

7

13

23.59

200×100

5.5

8

13

27.57

250×125

248×124

5

8

13

32.89

250×125

6

9

13

37.87

300×150

298×149

5.5

8

16

41.55

300×150

6.5

9

16

47.53

350×175

346×174

6

9

16

53.19

350×175

7

11

16

63.66

400×150

400×150

8

13

16

71.12

400×200

396×199

7

11

16

72.16

400×200

8

13

16

84.12

450×150

450×150

9

14

20

83.41

450×200

446×199

8

12

20

84.95

150×200

9

14

20

97.41

500×150

500×200

10

16

20

98.23

500×200

496×199

9

14

20

101.3

500×200

10

16

20

114.2

506×201

11

19

20

131.3

600×200

596×199

10

15

24

121.2

600×200

11

17

24

135.2

606×201

12

20

24

153.3

700×300

692×300

13

20

28

211.5

700×300

13

24

28

235.5

800×300

792×300

14

22

28

243.4

800×300

14

26

28

267.4

900×300

890×299

15

23

28

270.9

900×300

16

28

28

309.8

912×302

18

34

28

364.0

H Beam Steel Material

Q235: A common carbon structural steel known for its good overall mechanical properties and excellent weldability, making it suitable for general construction and structural applications.

Q345: A low-alloy, high-strength structural steel with greater load-bearing capacity, widely used in buildings, bridges, and heavy-duty structures.

Q420: A high-strength structural steel that offers enhanced durability and superior corrosion resistance, ideal for projects requiring higher performance standards.

Special Materials: Other customized steel grades are available to meet specific engineering and project requirements.

Key Features & Advantages

Wide flange design for efficient load-bearing

High structural strength and dimensional stability

Good weldability and fabrication performance

Consistent section geometry ensured by Shineyond Group’s quality control

Suitable for heavy-duty and long-span structures

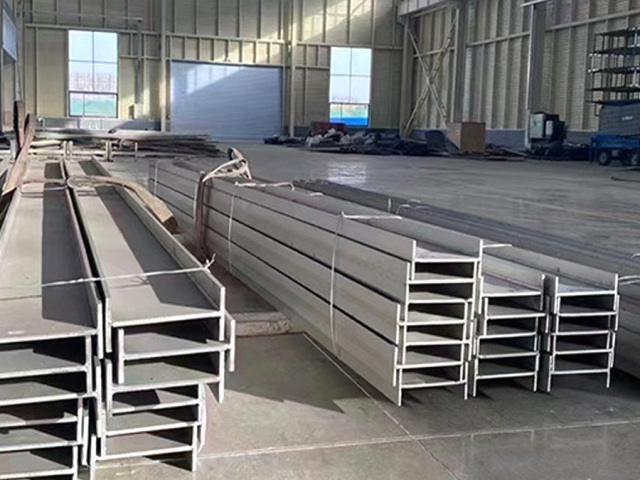

Applications

Shineyond Group H beam steel is commonly used in:

Steel structure buildings and warehouses

Bridges and transportation facilities

Industrial plants and equipment platforms

Columns and beams in large-span frameworks

Hot Rolled H Beam vs I Beam

Feature H Beam I Beam Flange Width Wider and equal thickness Narrower, tapered Load Capacity Higher, better for large spans Lower, suitable for small structures Weight Distribution More uniform Less uniform Applications Heavy construction, bridges, infrastructure Light construction, smaller frameworks Hot rolled H beams are preferred for large-scale projects due to their superior strength and durability.

Common Sizes of H Beam Steel

Height (mm) Flange Width (mm) Web Thickness (mm) Length (m) 100 – 200 100 – 150 5 – 8 6 / 9 / 12 250 – 400 125 – 200 6 – 12 6 / 9 / 12 450 – 600 150 – 250 8 – 20 6 / 9 / 12 700 – 1000 200 – 300 10 – 30 6 / 9 / 12 Why Choose Shineyond Group?

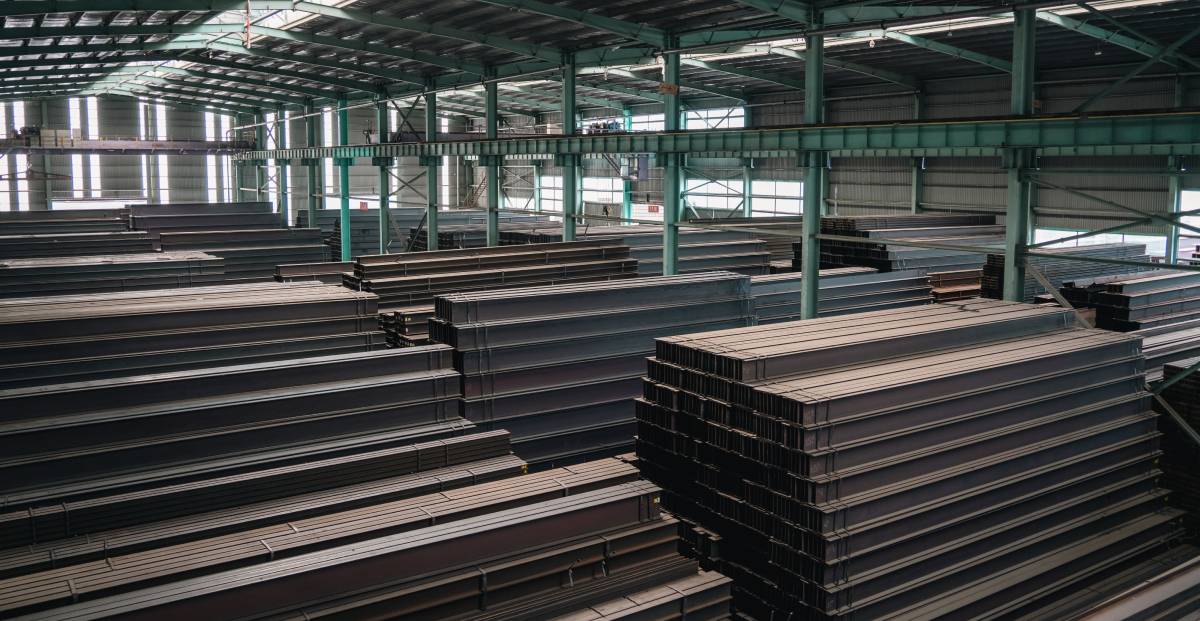

Global Supplier – Exporting to Africa, South America, Middle East.

High Quality Standards – Products comply with ASTM, EN, JIS, and GB.

Competitive Prices – Direct mill supply ensures lower costs.

Fast Delivery – Strong logistics network and sufficient stock.

Project Support – Technical consultation for construction and infrastructure projects.

FAQ – H Beam Steel

Q:What is H beam steel mainly used for?

A:It is used as a primary structural component in buildings, bridges, and industrial frameworks.

Q:Is H beam steel supplied by Shineyond Group suitable for welding?

A:Yes, it offers good weldability and supports standard fabrication processes.

Q:Which standards does Shineyond Group supply?

A:Common standards include ASTM, EN, and JIS.

Q:Can custom sizes be provided?

A:Yes, Shineyond Group offers custom lengths and section sizes based on project requirements.

Looking for a reliable H beam steel supplier?

Contact Shineyond Group for technical consultation, specifications, and competitive quotations tailored to your project.

H Beam Steel | Steel H Beams Supplier

WhatsApp / Tel / Wechat

Contact us via email

Still deciding? Get samples first, Contact US !

Products Category

Tag list

Hot rolled H-shaped steel

Welding H-shaped steel

Wide flange H-shape steel

Narrow flange H-shape steel

Building steel structural support

Bridge support

Get a Free Quote

Note: Please leave your email address, our professionals will contact you as soon as possible!