Steel Angle | Angle Steel Manufacturer & Supplier

WhatsApp / Tel / Wechat

Still deciding? Get samples first, Contact US !

View similar products

- Product Description

-

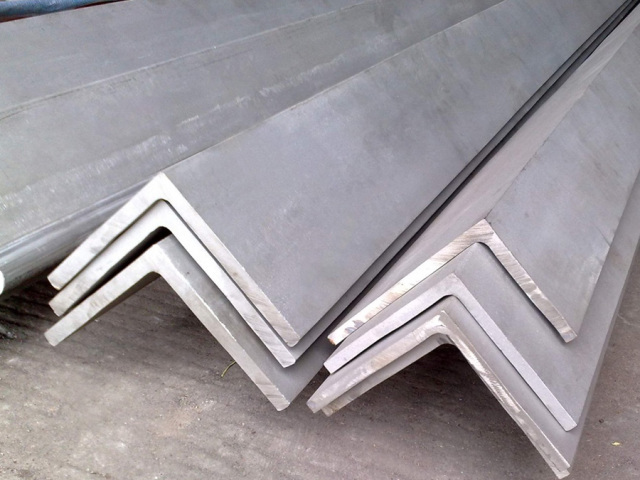

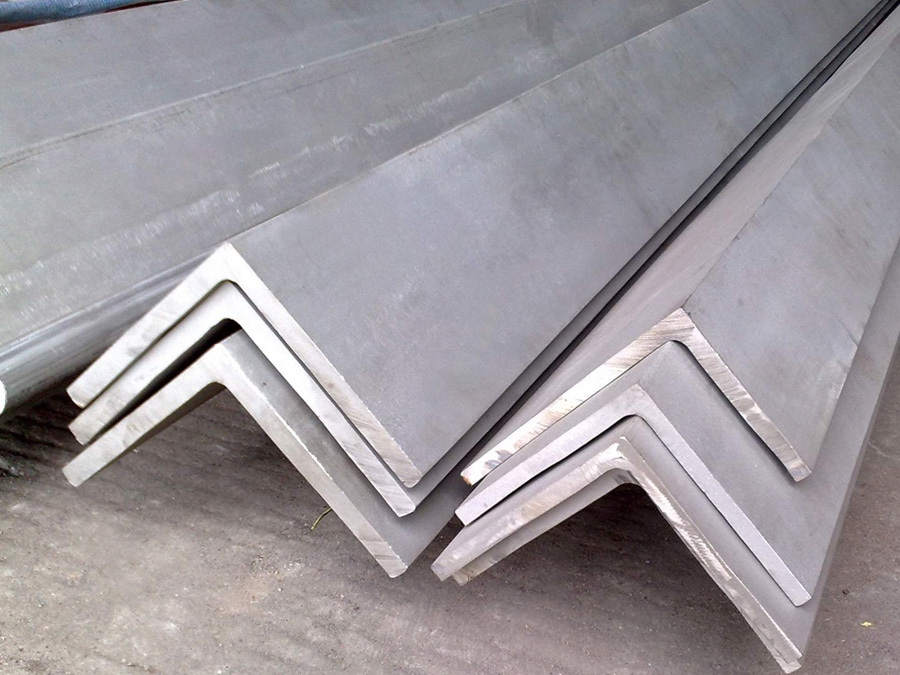

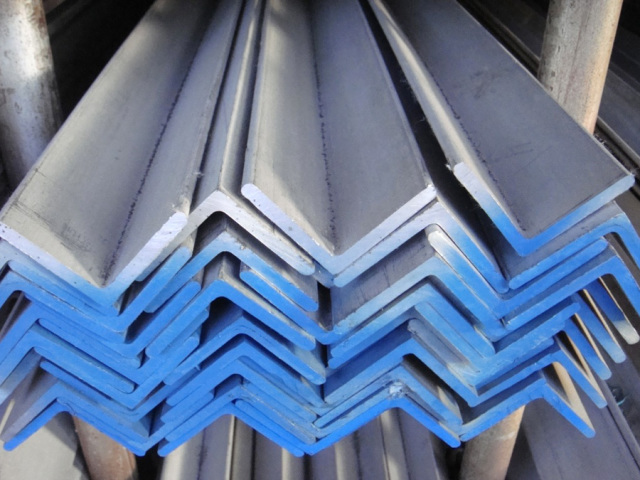

Steel Angle, also known as angle steel, is an L-shaped structural product made from carbon steel and widely used in construction and industrial projects. It is commonly produced through the Hot Rolled process, which gives it reliable strength, good toughness, and stable performance under load. Thanks to its simple shape and strong load-bearing capacity, steel angle is ideal for frames, supports, brackets, and structural reinforcement in buildings, machinery, and infrastructure applications.

Steel Angle Specifications

Specifications

Description

Size

20mm x 20mm to 200mm x 200mm

Thick

3mm to 20mm

Wide

20mm to 200mm

Length

3m to 12m

Material

Q235、Q345、Q420 etc.

MOQ

None

Delivery time

In stock

Packing

Strap

Size

Qide(mm)

Thick(mm)

Legth(m)

Equal

20×20

20

3、4

3-9

25×25

25

3、4

3-9

30×30

30

3、4

3-9

36×36

36

3、4、5

3-9

40×40

40

3、4、5

3-9

45×45

45

3、4、5、6

4-12

50×50

50

3、4、5、6

4-12

56×56

56

3、4、5、8

4-12

63×63

63

4、5、6、7、8、10

4-12

70×70

70

4、5、6、7、8

4-12

75×75

75

5、6、7、8、10

4-12

80×80

80

5、6、7、8、10

4-12

90×90

90

5、6、7、8

4-19

100×100

100

6、7、8、10、12、14、16

9-19

110×110

110

7、8、10、12、14

4-19

125×125

125

10、12、14

4-19

140×140

140

10、12、14、16

4-19

160×160

160

10、12、14、16

6-19

180×180

180

12、14、16、18

6-19

200×200

200

14、16、18、20、24

6-19

Unequal

2.5/16

25

16

3、4

3.2/2

32

20

3、4

4/2.5

40

25

3、4

4.5/2.8

45

28

3、4

5/3.2

50

32

3、4

5.6/3.6

56

36

3、4、5

6.3/4

63

40

4、5、6、7

7/4.5

70

45

4、5、6、7

7.5/5

75

50

5、6、8

8/5

80

50

5、6、7、8

9/5.6

90

56

5、6、7、8

10/6.3

100

63

6、7、8、10

Customized sizes, lengths, and coatings are available upon request.

Material

Angle steel raw materials are generally used is Q195, 10 #, 20 #, 35 #, 45 #, Q215, Q235, 304, 316, 20Cr, 40Cr, 20CrMo, 35CrMo, 42CrMo, 40CrNiMo, GCr15, 65Mn, 50Mn, 50Cr, 3Cr2W8V, 20CrMnTi, 5CrMnMo, etc.

Applications of Angle Steel

Steel Angle is widely used in construction and industrial applications due to its strength and versatility. It is commonly applied in building frames, steel structures, and structural reinforcement. Steel angle iron is also used in bridges, towers, and power transmission structures to provide stable support. In manufacturing, it serves as a key material for machinery frames, racks, brackets, and equipment supports. Additionally, steel angles are often used in shipbuilding, storage systems, and general fabrication where reliable load-bearing performance is required.

Common Sizes of Steel Angle Iron

Size (mm) Thickness (mm) Length (m) 20×20 3 – 4 6 / 9 / 12 30×30 3 – 5 6 / 9 / 12 50×50 4 – 8 6 / 9 / 12 75×75 6 – 10 6 / 9 / 12 100×100 6 – 12 6 / 9 / 12 150×150 8 – 15 6 / 9 / 12 200×200 10 – 20 6 / 9 / 12 Custom dimensions are available upon project request.

Equal Angle Iron vs Unequal Angle Iron

Type Shape Common Uses Advantages Equal Angle Iron Both sides equal Structural frames, reinforcement Balanced load distribution Unequal Angle Iron Sides of different lengths Bridges, towers, special designs Greater flexibility for engineering Steel Angle Iron vs Other Steel Products

Product Shape Main Use Advantages Angle Iron (L-shape) L-shaped Frames, reinforcement Strong at corners, versatile Flat Bar (Rectangle) Flat rectangular General fabrication Wide surface contact Channel Steel (U-shape) U-shaped Beams, supports High bending resistance I-Beam / H-Beam I or H cross-section Heavy structures Strong load capacity Why Choose Shineyond Group?

Global Supplier – Serving Africa, South America, Middle East with stable supply.

High Quality Standards – Products comply with ASTM, EN, JIS, and GB.

Competitive Prices – Direct factory export to reduce costs.

Fast Delivery – Strong logistics network ensures timely shipment.

Project Support – Professional team provides technical advice and after-sales service.

FAQ

Q1: What is the difference between hot rolled and cold formed angle iron?

Hot rolled angle iron is stronger and suitable for heavy-duty structures, while cold formed angle iron has a smoother finish and tighter tolerance.

Q2: Can angle iron be galvanized?

Yes. Shineyond Group offers black, pickled, and galvanized angle irons for different applications.

Q3: What sizes are commonly available?

Equal angle: 20×20mm – 200×200mm, Unequal angle: 25×16mm – 200×150mm.

Q4: How long is the service life of galvanized angle iron?

Typically 20–30 years, depending on environmental conditions.

Q5: Do you provide samples?

Yes. Free samples are available upon request for quality testing.

Looking for a reliable Steel Angle supplier?

Contact Shineyond Group for specifications, pricing, and fast global delivery.

Steel Angle | Angle Steel Manufacturer & Supplier

WhatsApp / Tel / Wechat

Contact us via email

Still deciding? Get samples first, Contact US !

Products Category

Tag list

Building Angle steel

Equal Angle steel

Unequal Angle steel

Building support structure

Hot rolled Angle steel

Steel Angle

Angle Bar

Steel Angle Bar

Get a Free Quote

Note: Please leave your email address, our professionals will contact you as soon as possible!