Galvanized Steel Coil

WhatsApp / Tel / Wechat

Still deciding? Get samples first, Contact US !

- Product Description

-

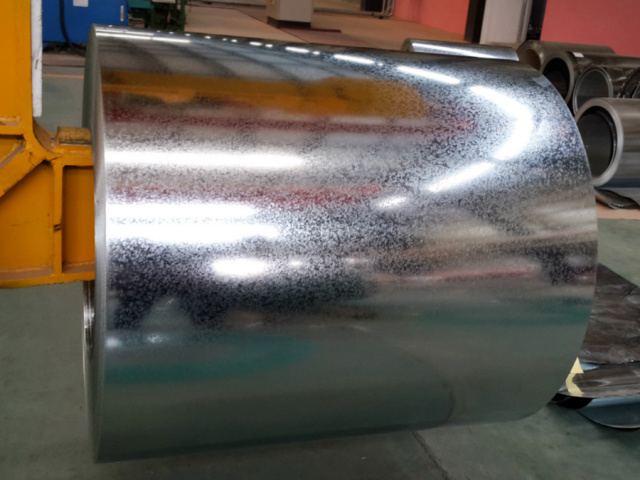

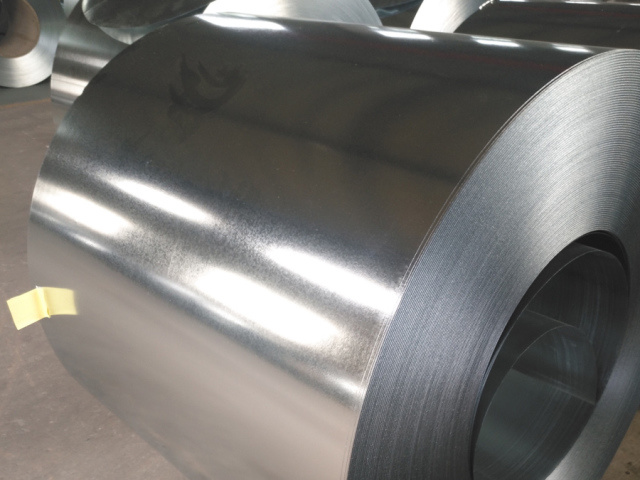

What are galvanized steel coils?

Galvanized steel coil is made by immersing a thin steel plate in a molten zinc bath, and a uniform zinc coating is formed on its surface, which can greatly improve the corrosion resistance and service life of the steel plate. Shineyond Group, as a galvanized steel coil suppliers, mainly adopts advanced continuous galvanizing process for efficient production. The steel coil is continuously fed into the galvanizing tank and dipped in the high-temperature molten zinc liquid to ensure the uniform adhesion of the zinc layer, which is suitable for construction, home appliances, automobiles and other fields.

Shineyond Group also produces alloy galvanized steel coils, which are hot-dip galvanized with a special heat treatment process. Immediately after the steel plate leaves the zinc tank, it is heated to about 500°C, which causes the zinc to form a dense zinc-iron alloy layer with iron. This alloy galvanized steel coil not only has excellent rust resistance, but also has excellent paint adhesion and welding properties, and is widely used in high-end manufacturing and precision machining industries.

Specification

Material

Steel, Zinc Alloy

Standard

SGCC, ASTM A653/653M, ASTM A36, JISG302, etc

Grade

DX51D, DX52D, DC51D, DX54D, SGCC, SGCD, SECC, etc

Thickness

0.12-3.50mm

Width

100-1250mm

Zinc Layer

30-275g/㎡

Inner Diameter

508/610mm

Coil Weight

3-4tons, 4-6tons or according to customer requirements

Spangle

no spangle, minimized spangle, maximum spangle, regular spangle

Surface Treatment

oiled, passivated or chrome-free passivated, passivated + oiled

MOQ

36 tons

Delivery Time

about 35 days

Package

Standard export package

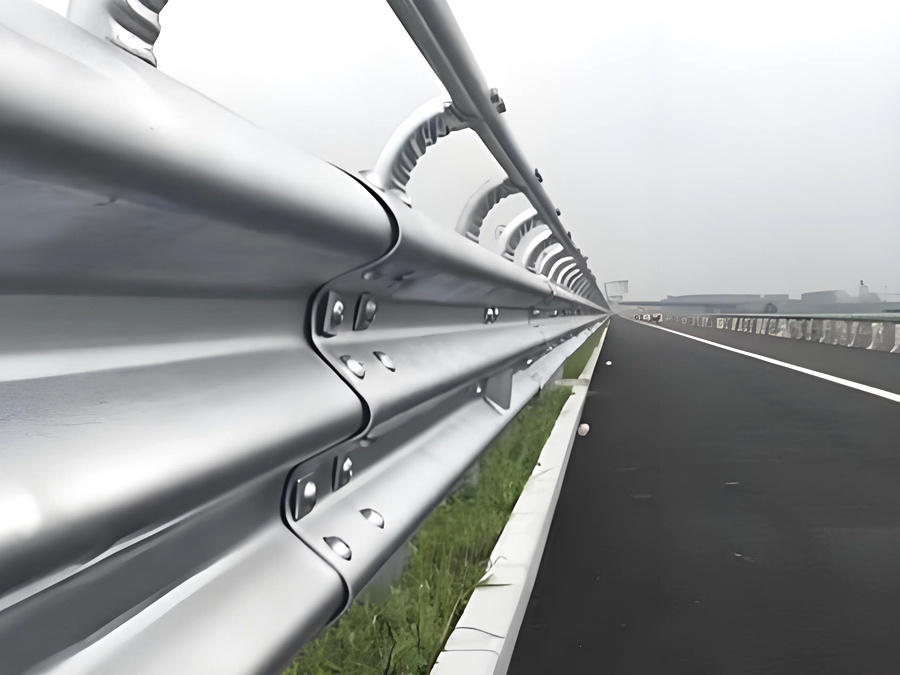

steel galvanized coil Applications

Galvanized steel coil is widely used in ship, automobile, Bridges, buildings, machinery, pressure vessels and other manufacturing industries.

1. Building & Construction:Roofing; Terrace; Window Frame;

2. Door:Rolling-up Door; Shutter; Mobile House;

3. Interior Decorations:Wall; Door Frame; Steel Structure; Screen; Ceiling; Elevator.

4. Household Appliances:Fridge; Washing Machine; Microwave Oven; Air-Conditioner; Duplicating Machine, etc.

Advantages

1. Strong anti-corrosion properties: galvanized steel coils undergo a number of processes such as hot-dip galvanizing during the production process, forming a uniform and dense zinc layer, which can effectively isolate the steel coils from contact with the external environment, thus preventing the purpose of corrosion. The zinc layer has good corrosion resistance and can maintain the corrosion resistance of the steel coil for a long period of time, even in harsh environments.

2. Good durability: Due to the excellent anti-corrosion properties of galvanized steel coils, the surface condition and service life of steel coils can be maintained for a long time. The zinc layer on the surface of steel coils can also play a role in reducing oxidized corrosion and prolonging the service life.

3. Aesthetically pleasing: galvanized steel coils have a good appearance, usually using galvanizing, spraying and other processes, you can form a layer of beautiful and strong outer layer on the surface of the steel coil. This kind of surface treatment is low-cost, but also has a high applicability, suitable for a variety of different occasions and environments.

4. Good processing performance: galvanized steel coils have good processing performance, whether it is shearing, stamping, bending or welding, can easily cope with different design needs. Its good ductility and plasticity make the galvanized steel coil not easy to break or deformation in the process, to ensure the stability and consistency of product quality.

5. Wide range of applications: Galvanized steel coils are widely used in various fields such as construction, furniture, automobile, electrical appliances and machinery.

6. Good economy: galvanized steel coils have significant cost advantages. Its corrosion resistance extends the service life of the material and reduces the frequency of replacement and repair due to corrosion, thus reducing long-term maintenance costs. In addition, the production process of galvanized steel coil is relatively mature, high production efficiency, cost control, making its market price competitive.

7. Good environmental friendliness: With the increasing awareness of environmental protection, recycling of used galvanized steel coils has become an industry trend, providing an additional source of income for enterprises. This further enhances the economic and environmental value of galvanized steel coils.

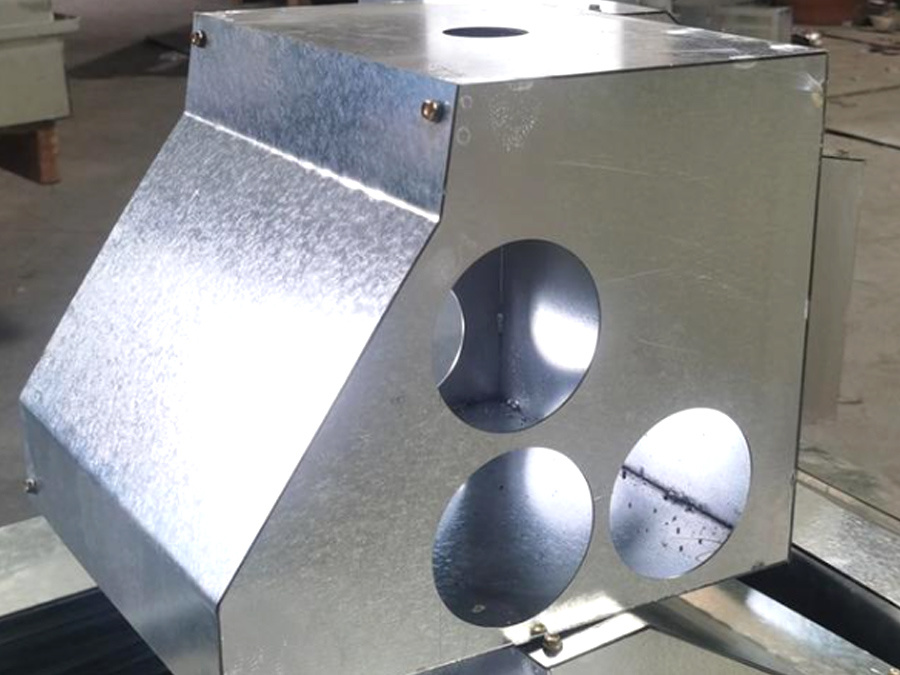

Production Process

1. Coil pickling: Steel coils to be galvanized are put into the acid solution for pickling with the purpose of removing oxides, oils and rusts from the steel surface to ensure the galvanizing effect.

2. Cleaning: After pickling, the surface of the steel coil is rinsed with water to remove residual acid and harmful substances such as chloride ions.

3. Pre-treatment: Put the cleaned steel coil into the pre-treatment tank to form a protective film on the steel surface through chemical reaction to increase the bonding force between the steel coil and the zinc solution and improve the quality of the coating.

4. Baking: After pretreatment, the steel coil is baked to make it completely dry for the subsequent zinc dipping process.

5. Zinc dipping: The baked coil is dipped into molten zinc to form a zinc layer to protect the coil from corrosion. The dipping time and temperature are adjusted according to requirements to achieve the desired galvanizing quality. 5.

6. Cooling: After dipping, the coils are cooled to allow the zinc layer to solidify quickly and to ensure the quality of the coating.

7. Coiling: After cooling, the galvanized steel coils are re-coiled and inspected for quality, including coating thickness, adhesion, and uniformity.

Galvanized Steel Coil

WhatsApp / Tel / Wechat

Still deciding? Get samples first, Contact US !

Products Category

Tag list

Galvanized steel coil

Zinc coated GI coil

Galvanized Steel Sheet In Coil

Galvanized Steel Sheet Roll

Galvanized Steel Coil For Roofing Sheet

Zinc Coated GI Steel Coil

Hot Dip GI Coil

Zinc coating steel coil

Electro galvanized steel coil

Inquire Now

Note: Please leave your email address, our professionals will contact you as soon as possible!

Related Products