3, 5, and 6 Reinforcing Bar: Sizes, Strength, and Uses

Reinforcing bars are a key material in the construction industry. They are used to strengthen concrete and improve safety in buildings and infrastructure. Among the many sizes available, 3 reinforcing bar, 5 reinforcing bar, and 6 reinforcing bar are widely used because they meet different structural needs. These bars are commonly produced from carbon steel, which provides strength, durability, and good bonding with concrete.

Understanding Reinforcing Bar Sizes

In the United States, reinforcing bars are identified using the imperial bar size system. Each bar number relates to its diameter measured in fractions of an inch. This system helps engineers quickly understand the size and strength of the bar.

3 reinforcing bar → 3/8 inch diameter

5 reinforcing bar → 5/8 inch diameter

6 reinforcing bar → 3/4 inch diameter

These measurements are important when calculating the nominal area, which is usually expressed in square inch. The nominal area affects how much force the bar can carry inside concrete.

Nominal Area and Physical Characteristics

The nominal area of a reinforcing bar increases as the bar size becomes larger. A larger area means higher load capacity. For example:

3 reinforcing bar has a smaller nominal area and is lightweight

5 reinforcing bar offers a balanced size and strength

6 reinforcing bar has a larger nominal area for heavy loads

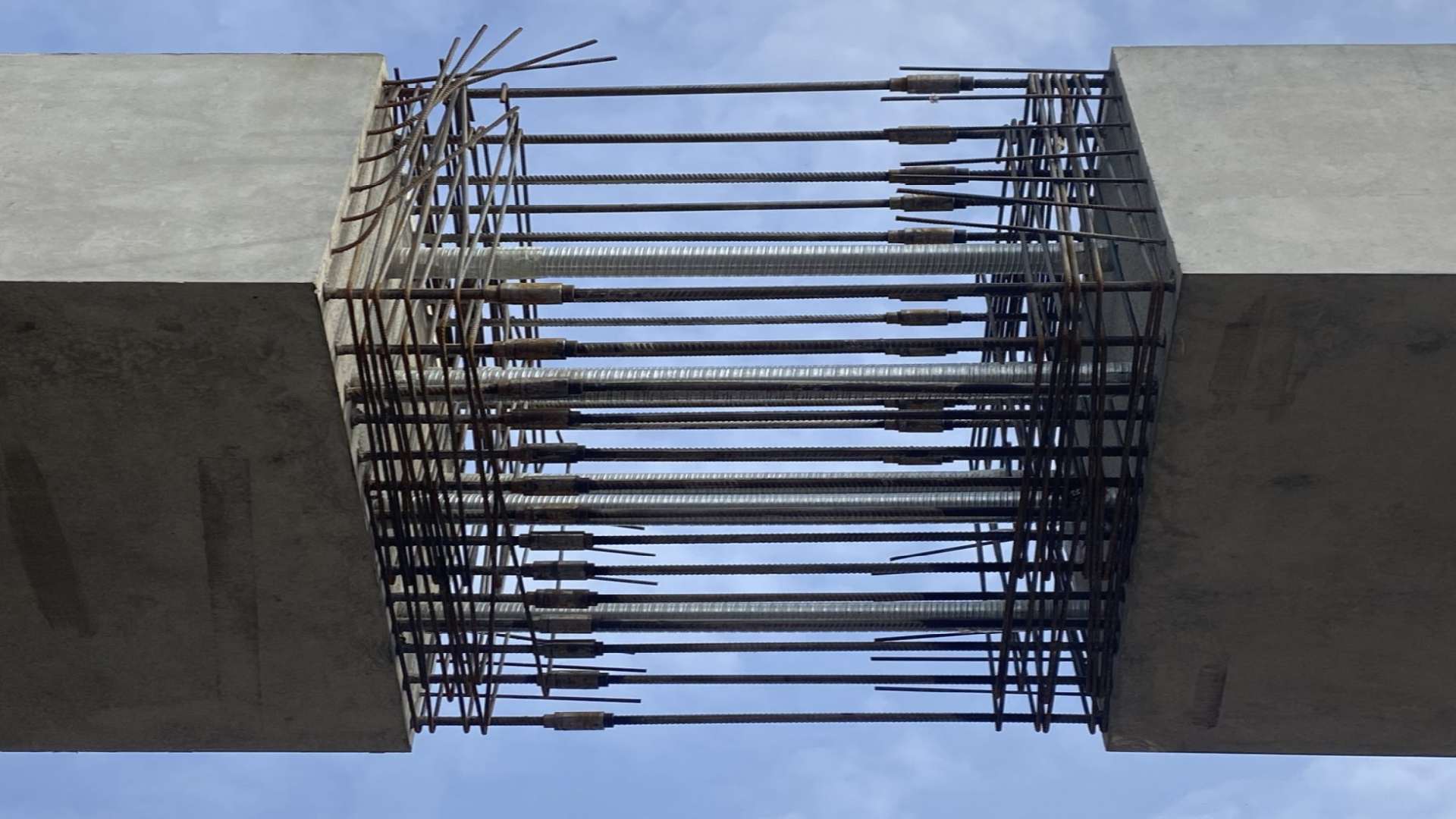

The physical characteristics of steel rebar include surface ribs, round shape, and high tensile capacity. These ribs improve the bond between the steel rebar and concrete, helping the structure resist cracking and bending forces.

Carbon Steel and Rebar Grades

Most reinforcing bars are made from carbon steel, which is valued for its strength and cost efficiency. Different rebar grades are used to meet various structural requirements. Rebar grades are defined mainly by their yield strength, which is the stress level at which steel begins to deform permanently.

Common rebar grades in the United States include:

Grade 40

Grade 60

Grade 75

Higher grades provide higher yield strength, making them suitable for demanding structural applications.

Applications of 3 Reinforcing Bar

The 3 reinforcing bar is commonly used in light construction work. Its smaller size makes it easy to bend and install.

Typical applications include:

Residential slabs

Sidewalks and pavements

Small foundations

Light concrete walls

It is often selected where crack control is needed but heavy structural loads are not required.

Applications of 5 Reinforcing Bar

The 5 reinforcing bar is one of the most popular choices in the construction industry. It provides a strong balance between strength and flexibility.

Common uses include:

Building foundations

Beams and columns

Retaining walls

Commercial concrete structures

Because of its reliable performance, this size is widely specified in structural designs.

Applications of 6 Reinforcing Bar

The 6 reinforcing bar is designed for heavy-duty construction. With a larger diameter and higher nominal area, it can support greater loads.

It is often used in:

Bridges and highways

Industrial buildings

High-rise structures

Large concrete footings

This bar size is frequently combined with higher rebar grades to achieve greater yield strength.

Conclusion

The 3 reinforcing bar, 5 reinforcing bar, and 6 reinforcing bar are essential materials in modern concrete construction. Made from carbon steel and defined by imperial bar size standards in the United States, these steel rebar products differ in nominal area, physical characteristics, and yield strength. By understanding rebar grades and proper applications, builders and buyers can choose the right reinforcing bar to ensure strength, safety, and long-term performance in concrete structures.