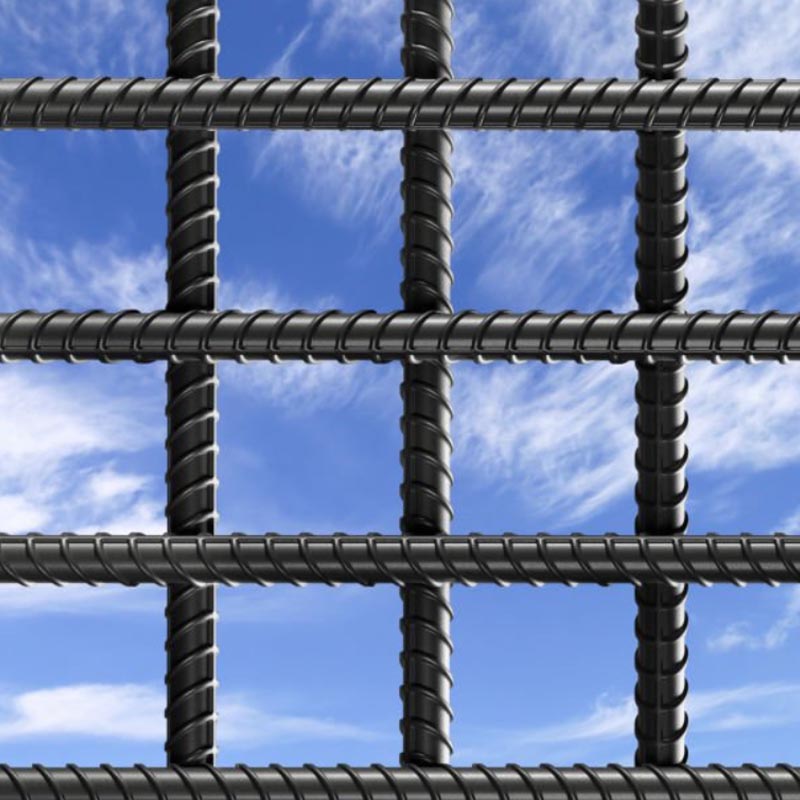

Reinforcing Bar for Strong and Lasting Concrete Projects

Reinforcing Bar—yeah, that steel stuff you see in concrete—is way more important than it looks. Most people just call it reinforcement steel, or sometimes “rebar,” but whether you say “reinforcing bar” or “rebar,” the idea is the same: it makes concrete much stronger. Concrete alone is great at handling weight from the top, but it’s not so good when things try to pull or bend it. That’s where steel comes in. Together, they make structures that can last decades without major problems.

Even small projects benefit from reinforcement. A simple concrete slab without steel is more likely to crack over time, especially if it’s exposed to temperature changes, heavy furniture, or small movements in the foundation. Adding reinforcing bar helps prevent these issues, giving you a longer-lasting and safer structure.

So, How Does It Actually Work?

Concrete can crack if it bends, shakes, or takes a big hit. That’s where reinforcement steel steps in. The steel carries tension forces that concrete can’t handle by itself. Plus, concrete and steel expand at almost the same rate when it gets hot, which is super handy because it keeps the whole structure stable.

In places like the United States, steel bars are often measured using the imperial bar size system. Engineers also check the nominal diameter and cross-section in square inch so they know exactly how much load each bar can carry. This stuff is crucial when you’re talking about beams, slabs, or foundations—you don’t want to guess here. A beam with the wrong bar size might bend or crack, which could cost a fortune to fix. So engineers carefully calculate how many bars are needed, what size, and where to place them.

What’s It Made Of?

Most reinforcement today is carbon steel. Why? It’s strong, affordable, and easy to work with. You can bend it, weld it, or cut it on site without messing up its strength. That’s why it’s used everywhere—from homes to big bridges. Different rebar grades give you different strength levels, so engineers can pick what’s needed—whether it’s a small house or a massive bridge.

And those ribs on the bars? Not just decoration. They grip the concrete, so the steel doesn’t slip around. This grip spreads the load evenly and helps prevent cracks and failures. Some projects even use epoxy-coated or stainless steel bars, especially in marine or coastal areas where corrosion could be a problem.

Why You Can’t Skip It

Concrete is amazing, but it has a weak spot: tension. Without steel, it would crack and fail under stress. Here’s why people keep using reinforcement:

Tougher structures: It carries tension so concrete doesn’t crack.

Long-lasting: Helps buildings survive wind, vibration, and movement over time.

Flexible designs: Makes it easier to create curved shapes, thin slabs, or long spans.

Cost-effective: Gives you strong concrete without breaking the budget.

Quick and easy: You can bend, cut, or tie it fast on site.

Even small reinforcements can make a huge difference in the lifespan of a building. It’s not just about heavy structures; even residential slabs benefit from a few well-placed bars.

Where You’ll See It

Honestly, it’s everywhere. Reinforced concrete shows up in almost every building and infrastructure project:

Foundations, footings, and retaining walls

Slabs, beams, and columns in homes, offices, or factories

Roads, bridges, and highways

Tunnels and underground railways

Water tanks, dams, and marine projects

Precast panels, pipes, and piles

Even in salty coastal areas, engineers make adjustments—like epoxy-coated bars—to make sure the steel lasts longer. It’s not overkill; it’s just smart planning for long-term durability.

Picking the Right Steel

Choosing the right reinforcement is actually pretty simple if you know what to look for:

Bar size: Check the imperial bar size or nominal diameter. Bigger bars = more strength.

Rebar grades: Stronger grades for bridges or high-rise buildings.

Material: Most are carbon steel; some projects need stainless or coated steel.

Surface condition: Clean, ribbed bars bond better.

Design specs: Make sure it matches the national or international standards.

These little details make a huge difference in safety and longevity. Even small mistakes in bar selection can lead to cracking or uneven stress distribution in the concrete.

How It Helps in Modern Construction

The construction industry loves reinforcement because it’s strong, cheap, and available almost everywhere. From roads and airports to renewable energy foundations, reinforced concrete keeps everything standing tall. With different sizes, nominal diameters, and rebar grades, engineers have tons of options for every type of project.

High-rise buildings, for example, rely heavily on proper reinforcement. Columns, beams, and slabs all need bars that can handle massive loads. Bridges are even trickier—they face constant traffic, wind, temperature changes, and sometimes earthquakes. Choosing the right bar size and grade ensures they remain safe for decades.

Even smaller projects, like residential homes or garden walls, benefit from reinforcement. It may seem overkill at first, but a few well-placed bars prevent cracking, sagging, and future repairs. Over time, this saves homeowners both money and stress.

Finding a Good Supplier

The last thing you want is steel that doesn’t meet standards. Reliable suppliers give you consistent bar sizes, correct strength, and materials that perform exactly as expected. Good quality means easier installation, better bonding with concrete, and a longer-lasting structure.

We supply high-quality reinforcement steel, whether you’re building a small house or a massive bridge. You get the right bar size, grade, and material, plus competitive pricing and fast delivery. Basically, we make sure your concrete stands strong for years without any headaches.

Wrapping It Up

Reinforcing Bar isn’t just another construction material—it’s what makes concrete actually work the way it’s supposed to. From small residential projects to huge infrastructure, it adds tensile strength, durability, and reliability. By choosing the right bar size, nominal diameter, material, and rebar grade, and sourcing from a trusted supplier, you can ensure your structures will last a long time.

So next time you see a concrete slab or a bridge, take a closer look—you’re looking at a combination of smart engineering, carbon steel, and a little thing called reinforcing bar that quietly keeps everything standing.