What Is Carbon Steel Sheet? Types, Properties

Carbon steel sheets are one of the most commonly used materials in the steel industry. They are popular because they are strong, versatile, and cost-effective. The carbon content in these sheets ranges from 0.05% to 2.0%. By adjusting the carbon content and using different treatment processes, manufacturers can produce different grades of steel. Each grade can be used for different purposes in various industries such as construction, automotive, shipbuilding, and machinery.

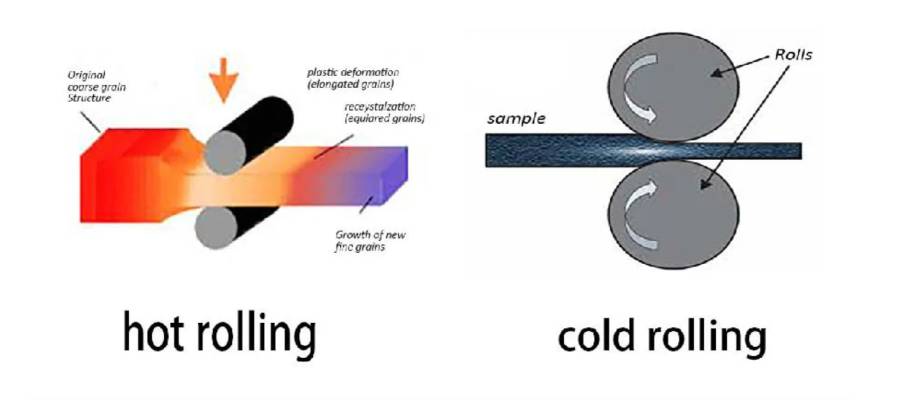

These steel sheets are usually made in two main ways: hot rolling (HR) and cold rolling (CR). Hot-rolled sheets are formed at high temperatures. This process makes the steel strong, flexible, and tough. However, the surface of hot-rolled steel is rough. Cold-rolled sheets are further processed at room temperature. This gives a smoother surface, tighter dimensions, and better mechanical properties. The choice between hot-rolled and cold-rolled sheets depends on how the steel will be used.

Types of Carbon Steel Sheet

Steel sheets can be divided into three main types based on their carbon content. Each type has different characteristics and uses.

1. Mild Steel Sheet (Low Carbon Steel)

2. Mild steel has less than 0.25% carbon. It is very ductile, which means it can bend and stretch easily without breaking. It also has good weldability and can be formed into different shapes with little effort. Common grades of mild steel include Q195, Q235, and A36. This type of steel is often used in construction projects, building frames, and general engineering. It is not the hardest steel, but it is easy to work with and affordable.

3. Medium Carbon Steel Sheet

4. Medium carbon steel has 0.25% to 0.60% carbon. It offers a balance between strength and flexibility. This makes it suitable for mechanical parts, automotive components, and machinery. Medium carbon steel is stronger than mild steel but still has some ductility. It is also used in applications where moderate wear resistance is needed.

5. High Carbon Steel Sheet

6. High carbon steel contains 0.60% to 1.0% carbon. This type of steel is very hard and wear-resistant. It is often used for tools, cutting equipment, and heavy-duty industrial applications. High carbon steel is strong but less flexible. It is harder to weld compared to low or medium carbon steel.

Manufacturing Process of Carbon Steel Sheets

There are two main methods to produce these sheets: hot rolling and cold rolling.

Hot Rolled Steel Sheets (HR): These sheets are made at high temperatures. Hot rolling gives the steel good strength, toughness, and flexibility. Hot-rolled sheets are often used in construction, shipbuilding, and large industrial projects where precision is less important, but strength is essential.

Cold Rolled Steel Sheets (CR): These sheets are further processed at room temperature. Cold rolling improves the surface finish and makes the steel more precise. Cold-rolled sheets are often used for automotive parts, appliances, and projects where smooth surfaces and tight tolerances are required.

Key Properties of Carbon Steel Sheets

Carbon steel sheets have several important properties:

High tensile and yield strength, which means they can handle heavy loads without breaking

Good machinability and weldability, making them easy to work with

Compatibility with surface treatments like galvanizing, painting, or coating

Excellent formability, so they can be bent, shaped, or rolled easily

Cost-effective, which makes them a good choice for many industries

Applications of Carbon Steel Sheets

Because of their strength and versatility, these sheets are used in many industries. In construction, they are used for building frames, structural supports, and roofing. In the automotive industry, they are used for car bodies, chassis, and parts. In shipbuilding, carbon steel sheets help make hulls and other structural parts. They are also used in machinery manufacturing, appliances, and general engineering.

Conclusion

Carbon steel sheets are a fundamental material for modern industry. They combine strength, durability, and affordability. Whether you need hot-rolled or cold-rolled sheets, these steel products provide reliable performance. Companies like ShineWing Group offer high-quality steel sheets that can meet different project requirements. With multiple grades and finishes available, carbon steel sheets remain a dependable choice for engineers, builders, and manufacturers around the world.

They are not only versatile but also economical. The combination of strength, formability, and cost-effectiveness makes them essential for everyday engineering and large industrial projects. Whether building bridges, cars, or machines, carbon steel sheets are often the preferred material for their balance of performance and value.