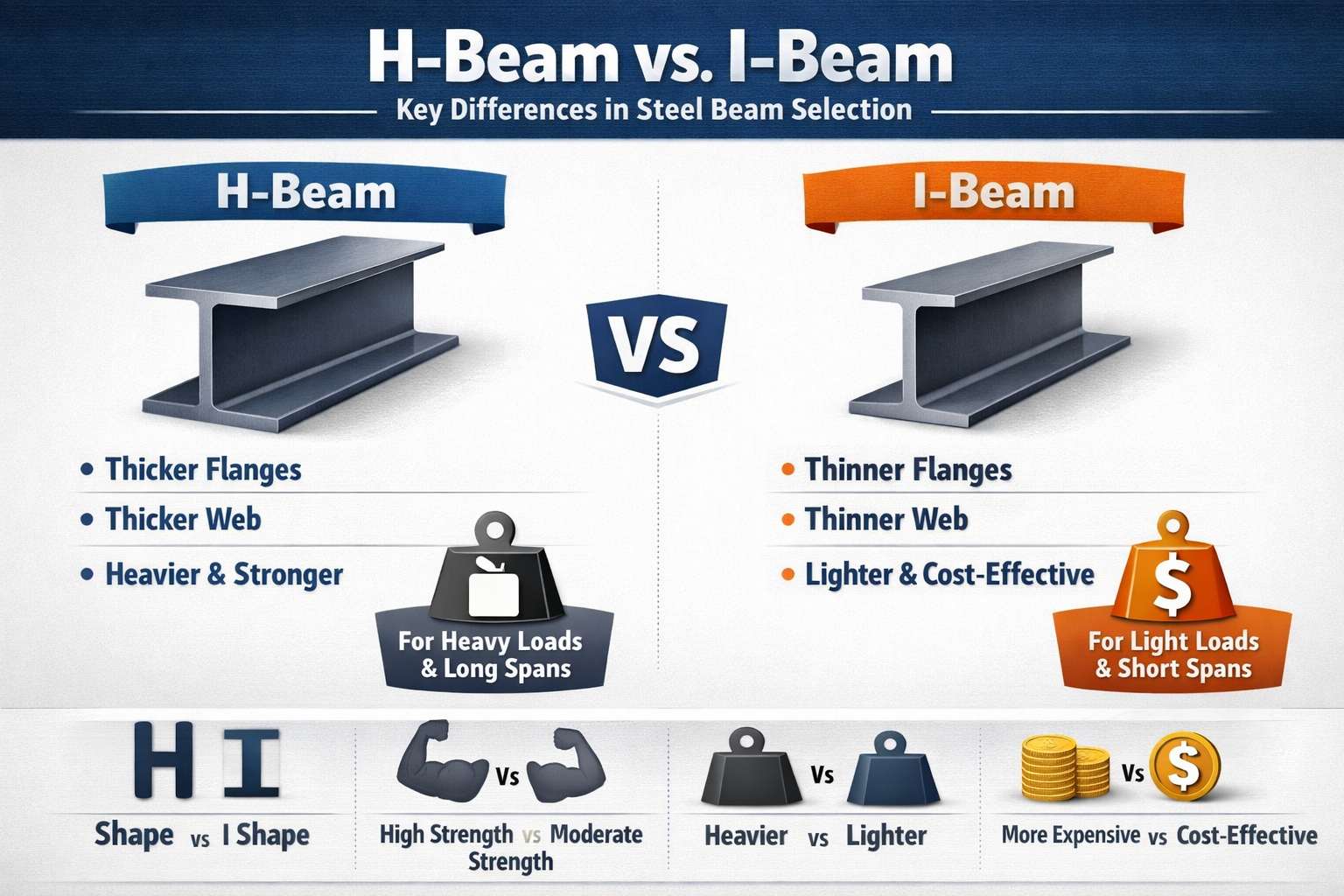

H-Beam vs. I-Beam: Key Differences in Steel Beam Selection

Steel beams are basic to structural engineering, letting us build things like open rooms, tall buildings, and strong bridges. If you don't know much about them, two key kinds, H-beams and I-beams, can seem almost the same. Though they both give support, they're made to handle various amounts of stress, length, and heaviness.

Picking the incorrect steel beam could cause extra expenses or, worse, cause the structure to fail. Here’s what you should know about these two industry standards.

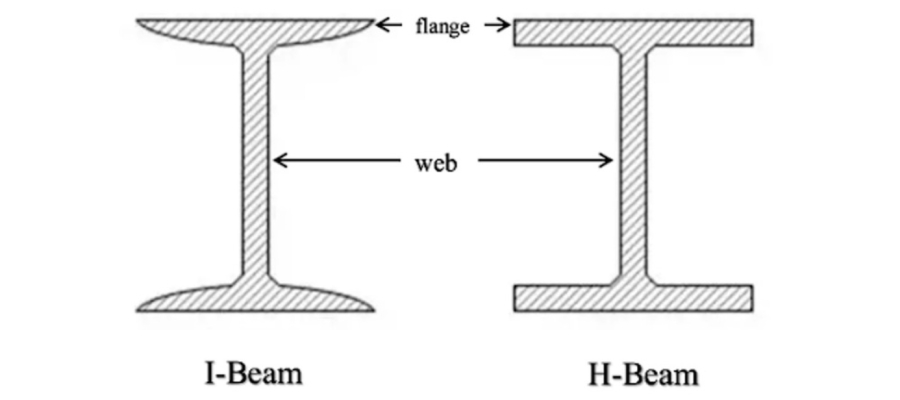

Geometric Profiles: The "H" and the "I"

H-beams and I-beams differ mainly in the shape of their cross-sections. The shapes matter because they affect how the steel withstands pressure.

The I-Beam (Standard Beam)

I-beams, sometimes called S-beams, have a design that features a thinner web and smaller flanges.

I-beams have a couple of unique traits. First, the inside of the flanges slopes, usually at a 1:10 ratio. This means the flange is thicker where it meets the web and thinner at the edges. Also, the web is always taller than the flanges are wide.

The H-Beam (Wide Flange Beam)

H-beams, also called W-beams, are made with a wider shape.

Unlike I-beams, H-beams have flanges that are parallel from the web to the edge, keeping a consistent thickness.

Also, many H-beams have flanges that are about as wide as the web is tall, which makes them look more square.

Weight and Load-Bearing Capacity

When comparing h beam vs i beam performance, weight is the deciding factor for structural integrity.

H-beams are heavier than I-beams of the same size because they have wider flanges and a thicker web. This extra weight means they can handle bigger loads.

H-beams are stronger than I-beams when it comes to resisting twisting forces. The wider flange on an H-beam gives it a bigger area to spread out stress from the side. In contrast, I-beams are really made to handle up-and-down bending.

Span Length: For steel beams in projects needing to cover over 30 feet without center supports, H-beams are usually the way to go. I-beams might buckle or sag if they're too long.

Manufacturing and Material Standards

The production of a steel beam involves hot-rolling steel through a series of rollers to achieve the desired shape.

I-Beams: These are usually made from a single piece of rolled steel. The machines that make I-beams follow common standards, which makes it easy to produce them in large quantities. They are also easy to find in common sizes.

H-Beam Creation: Regular H-beams are rolled, but for really big or special ones, they're often built-up. This means welding three plates together—two flanges and a web. This way, engineers can get exactly the size they need, even if it's not a standard size from the mill.

Most steel beams today are made with ASTM A992 steel. It's stronger for its weight than the old A36 steel, so it's the usual choice now for wide-flange beams.

Application: Where to Use Which?

The debate of h beam vs i beam often comes down to the specific environment and the scale of the build.

Residential and Light Construction

For a standard house renovation—such as removing a wall to create an open-plan kitchen—an I-beam is usually the preferred choice.

Advantage: It is lighter and easier for a small crew to install manually or with light machinery.

Space: Its narrower flanges allow it to be tucked away inside a standard wall or floor joist space more easily.

Heavy Industrial and Civil Engineering

For skyscrapers, large warehouses, and bridges, the H-beam is the undisputed king.

Advantage: Its ability to act as both a horizontal beam and a vertical column makes it versatile.

Safety: In regions prone to high winds or seismic activity, the lateral strength of the H-beam provides a critical safety margin that the I-beam lacks.

Cost-Benefit Analysis

Budgeting is key for any construction project. When figuring out the cost of a steel beam, keep these three things in mind:

Price per Foot: Since steel is sold by weight, the H-beam is more expensive per linear foot because it uses more raw material.

Installation Labor: An I-beam may save you money on crane rentals and labor hours because it is easier to maneuver.

Long-Term Value: If using an I-beam requires you to add extra support columns to prevent sagging, the H-beam might actually be the cheaper long-term solution by allowing for a "clear span" design.

Feature | I-Beam (S-Section) | H-Beam (W-Section) |

Flange Width | Narrow / Tapered | Wide / Parallel |

Weight | Lighter | Heavier |

Strength | Moderate | High |

Max Span | Up to 100 ft (rarely) | Over 300 ft (built-up) |

Common Use | Residential / Hoists | Skyscrapers / Bridges |

Summary: The Final Verdict

Choosing between an h beam vs i beam isn't about which beam is "better," but which is more appropriate for the specific physics of your build.

Choose an I-beam if you are working on a smaller scale, have a limited budget, and only need to support vertical weight over a relatively short distance.

Choose an H-beam if you are building vertically (columns), spanning wide distances, or if the structure must withstand significant lateral forces like wind or heavy machinery vibration.

Important Safety Note: A steel beam is only as good as the engineering behind it. Never substitute one beam type for another without consulting a licensed structural engineer. They will perform the necessary calculations (such as the Area Moment of Inertia) to ensure your structure remains standing for decades to come.