What Is Steel Bllets? Properties, Uses, and Manufacturing Process

A Steel Billets is a semi-finished steel product that is used in a variety of applications, from construction to automotive manufacturing. But do you know what a billet is? How is it different from other steels such as slabs?

In this guide, we’ll explore:

The definition of billet steel

Its key properties and advantages

Common applications across industries

The manufacturing process

How it compares to other steel products

By the end, you’ll understand why billet steel is a crucial material in moder

what is a steel billets?

Steel billets is a solid, semi-finished steel product, generally in the shape of a square or rectangular cross-section. The product is produced by continuous casting or hot rolling and can be further processed into raw materials for bars, bars, wire rods, and other steel components.

Compared to slabs, which are mainly used for sheet production, or large billets with larger cross-sectional dimensions, billets are smaller and more adaptable, making them particularly suitable for manufacturing applications that require high precision.

Key Characteristics of Billet Steel

High strength and durability – Suitable for structural applications

Uniform composition – Ensures consistency in final products

Machinability – Easily forged, rolled, or extruded into different shapes

Weldability – Compatible with various welding techniques

Properties of Billet Steel

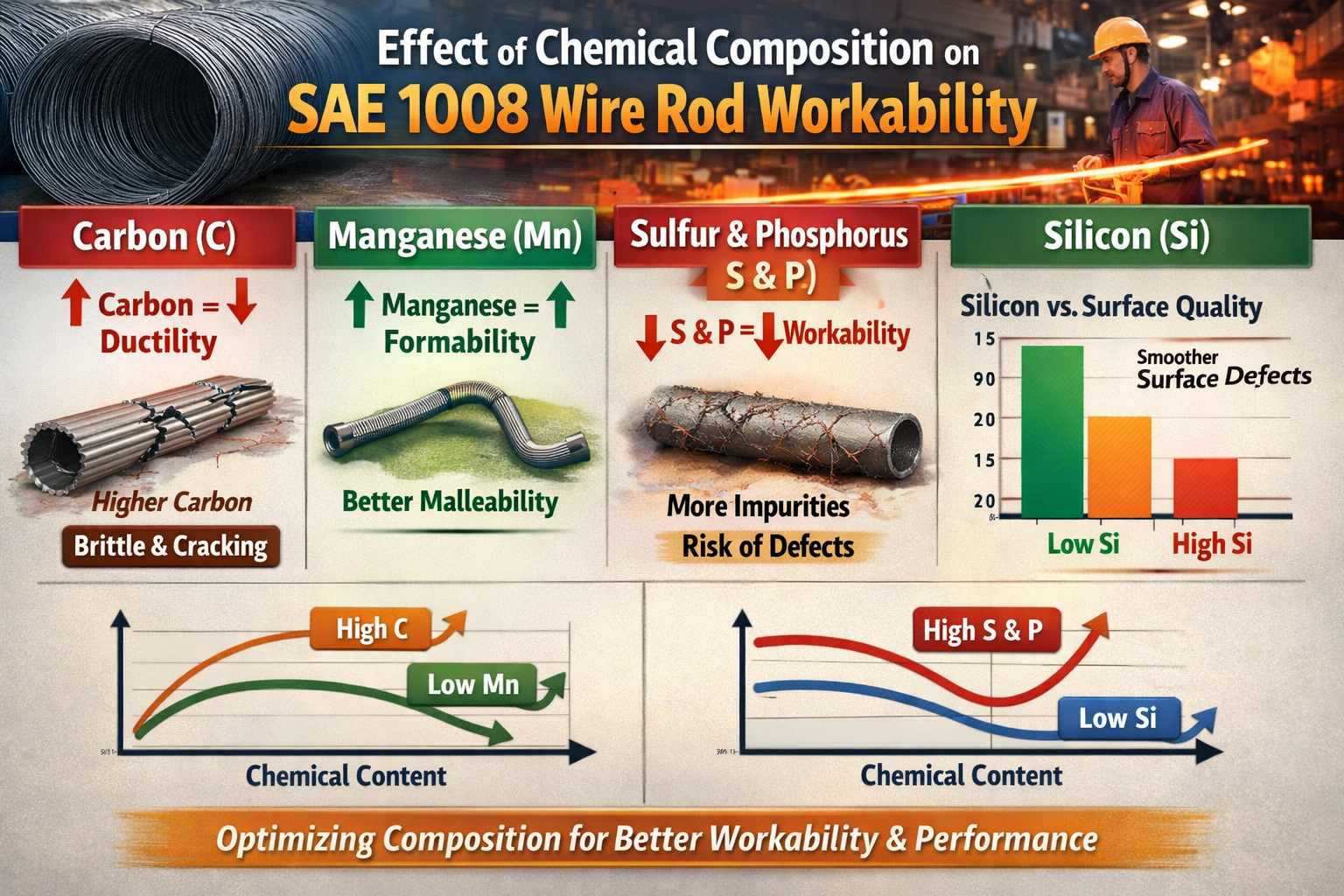

Billet steel’s properties depend on its chemical composition and manufacturing process. Common grades include low-carbon, medium-carbon, and high-carbon steel, each offering different benefits:

| Property | Description |

|---|---|

| Strength | High tensile strength, making it ideal for load-bearing structures. |

| Ductility | Can be stretched or bent without breaking (useful in wire and rod production). |

| Corrosion Resistance | Can be enhanced with coatings or alloying elements (e.g., stainless steel billets). |

| Thermal Conductivity | Retains structural integrity under high temperatures. |

These properties make billet steel a preferred choice for automotive, construction, and machinery manufacturing.

Common Uses of Billet Steel

Due to its versatility, billet steel is used in multiple industries:

1. Automotive Industry

Engine components (crankshafts, connecting rods)

Gear shafts and axles

Suspension parts

2. Construction & Infrastructure

Rebar and structural beams

Fasteners and bolts

Scaffolding components

3. Manufacturing & Machinery

Tool and die making

Hydraulic and pneumatic systems

Precision-machined parts

4. Energy Sector

Wind turbine shafts

Oil and gas drilling equipment

5. Consumer Goods

Hand tools

Bicycle frames

Hardware fittings

How Is Billet Steel Made? The Manufacturing Process

The production of billet steel involves several key steps:

1. Steelmaking (Primary Production)

Raw materials (iron ore, scrap steel) are melted in a blast furnace or electric arc furnace (EAF).

Alloying elements (carbon, manganese, chromium) are added to achieve desired properties.

2. Continuous Casting

Molten steel is poured into a continuous caster, forming long strands.

These strands are cut into smaller lengths, creating billets.

3. Hot Rolling (Optional)

Billets may be reheated and passed through rolling mills to refine dimensions.

This improves surface finish and mechanical properties.

4. Cooling & Finishing

Billets are cooled in a controlled environment to prevent internal stresses.

They are then inspected for defects before being shipped to manufacturers.

Steel Billets vs. Other Steel Forms

How does billet steel compare to similar products?

| Feature | Billet Steel | Bloom | Slab |

|---|---|---|---|

| Cross-Section | Small (≤150mm) | Large (>150mm) | Flat & wide |

| Primary Use | Bars, rods, wires | Structural beams | Sheets, plates |

| Flexibility | Highly machinable | Less versatile | Requires further rolling |

Billet steel is best for precision parts, while blooms and slabs are used for larger structural applications.

Conclusion: Why Choose Billet Steel?

Billets have high strength, versatility and economic benefits of universities, and have become the basic materials of modern manufacturing. Whether you are engaged in automobile, construction, or machinery production, you should carefully understand the characteristics and manufacturing process of products before choosing them, which can better help you choose the right steel grade.

Looking for High-Quality Steel billets?

If you need a reliable billet supplier, you can contact Shineyond Group, we offer certified materials that provide consistent quality. And you can get the manufacturer's preferential price, as well as high durability and excellent performance products from us.