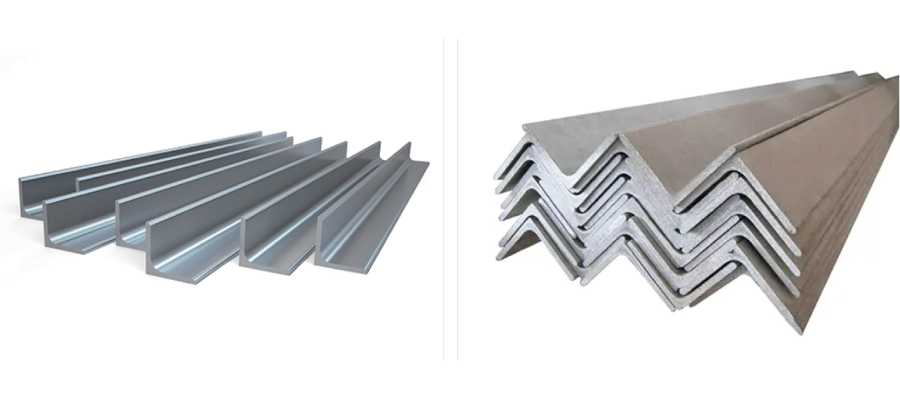

Steel Angle Iron: Definition, Features, and Uses

Steel angle iron, also known as steel angle or angle bar, is one of the most widely used structural steel products in construction and manufacturing. Thanks to its simple shape, high strength, and cost efficiency, it plays a key role in many load-bearing and support applications. This article explains what steel angle iron is, how it is made, its main types, key features, and common uses.

What Is Steel Angle Iron?

Steel angle iron is a long steel product with an L-shaped cross section. It consists of two legs that meet at a 90-degree angle. These legs can be equal in length or unequal, depending on design requirements.

Most angle irons are made from carbon steel, which offers a good balance of strength, toughness, and affordability. Due to its structural stability, steel angle iron is commonly used to support loads, reinforce frames, and connect components in various engineering projects.

Steel Angle Iron Manufacturing Process

Steel angle iron is typically produced through the hot rolled process. In this method, steel billets are heated to a high temperature above the recrystallization point and then rolled into the required angle shape.

Hot rolling provides several advantages:

Good mechanical strength

Uniform internal structure

Cost-effective production for large volumes

After rolling, the angles are cooled naturally, cut to length, and may undergo further surface treatment such as galvanizing or painting for corrosion protection.

Types of Steel Angle Iron

Steel angle iron can be classified in several ways based on leg size, surface treatment, and standards.

1. Equal Angle Steel

Both legs have the same width. This type is widely used in structural frameworks, towers, and general fabrication due to its balanced strength.

2. Unequal Angle Steel

The two legs have different widths. This design is suitable for applications where load distribution or space constraints require asymmetric support.

3. Galvanized Steel Angle

This type is coated with zinc to improve corrosion resistance. It is ideal for outdoor structures, humid environments, and coastal areas.

4.Hot Rolled Steel Angle

Manufactured by hot rolling process.

Offers good toughness and is suitable for heavy-duty applications.

Key Features and Advantages

Steel angle iron offers several important benefits that make it a preferred structural material:

High Strength and Load Capacity

The L-shape provides excellent resistance to bending and torsion, making it suitable for heavy loads.

Versatility

It can be cut, welded, drilled, and bolted easily, allowing flexible use in different projects.

Cost Efficiency

Compared with more complex steel sections, angle iron is economical while still providing reliable performance.

Wide Size Range

Available in various thicknesses and leg dimensions to meet different engineering needs.

Durability

When made from carbon steel and properly protected, it offers a long service life.

Common Applications of Steel Angle Iron

Because of its structural stability and adaptability, steel angle iron is used across many industries.

Construction and Infrastructure

In building projects, steel angle iron is used for:

Structural frames

Bracing and reinforcement

Stair supports

Roof trusses

It helps improve overall stability and load distribution in steel structures.

Manufacturing and Fabrication

Angle iron is widely applied in:

Machine frames

Equipment supports

Storage racks

Work platforms

Its ease of fabrication makes it ideal for custom metalwork.

Power and Communication Structures

Steel angle iron is commonly used in:

Transmission towers

Communication masts

Substation structures

Its strength and dimensional stability are critical for tall and exposed structures.

Transportation and Industrial Projects

It is also used in:

Railway components

Truck and trailer frames

Industrial shelving systems

In these applications, reliability and structural integrity are essential.

Standards and Specifications

Steel angle iron is produced according to international and regional standards to ensure quality and performance. Common standards include:

ASTM (such as ASTM A36)

EN standards

JIS standards

GB standards

Different grades define chemical composition, mechanical properties, and tolerances, allowing buyers to select the right product for their project.

Choosing the Right Steel Angle Iron

When selecting steel angle iron, consider the following factors:

Load requirements

Environmental conditions

Required size and thickness

Surface treatment needs

Applicable standards

For outdoor or corrosive environments, galvanized or coated angle iron is recommended.

Conclusion

Steel angle iron is a fundamental structural material known for its strength, versatility, and affordability. Made mainly from carbon steel through the hot rolled process, it is available in multiple types and sizes to suit a wide range of applications. From construction and infrastructure to manufacturing and industrial projects, steel angle iron continues to be a reliable solution for structural support and reinforcement.

Understanding its features and proper uses can help engineers, contractors, and buyers choose the right angle iron for long-lasting and cost-effective performance.