Standard Angle Iron Sizes and Size Chart

Angle iron is a common type of steel used in building, manufacturing, and other big projects. It makes frames, supports, towers, and steel structures strong and sturdy. Picking the right size of angle iron is important to make sure things are built well, don't waste materials, and stay within budget.

This guide tells you about standard angle iron sizes, shows you a chart of sizes, and gives you tips on how to pick the best size for what you're building.

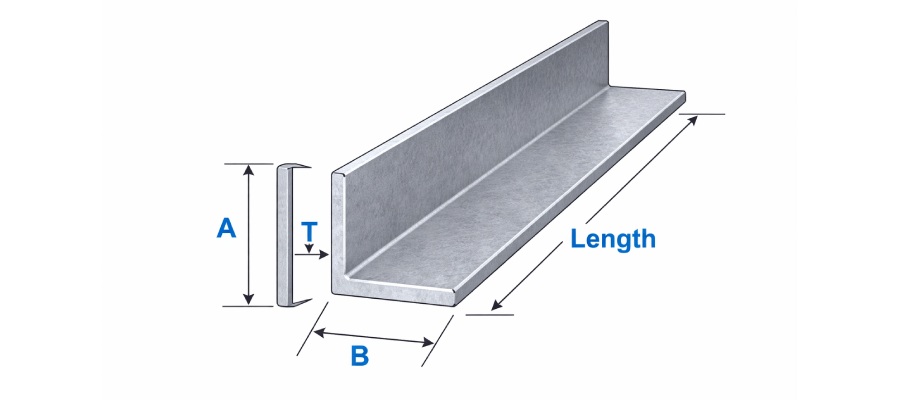

What Are the Sizes of Angle Iron?

Angle iron sizes are shown with three numbers:

Leg × Leg × Thickness

Like this:

40 × 40 × 4 mm means it's an equal angle with two 40 mm legs, and it's 4 mm thick.

75 × 50 × 6 mm means it's an unequal angle (the legs are different lengths).

You can usually find angle iron in two types:

Equal Angle – both legs are the same length

Unequal Angle – legs are different lengths; use these when you need something special for your structure.

Typical lengths are:

6 meters (you'll see this one the most)

9 or 12 meters (mainly for big building jobs)

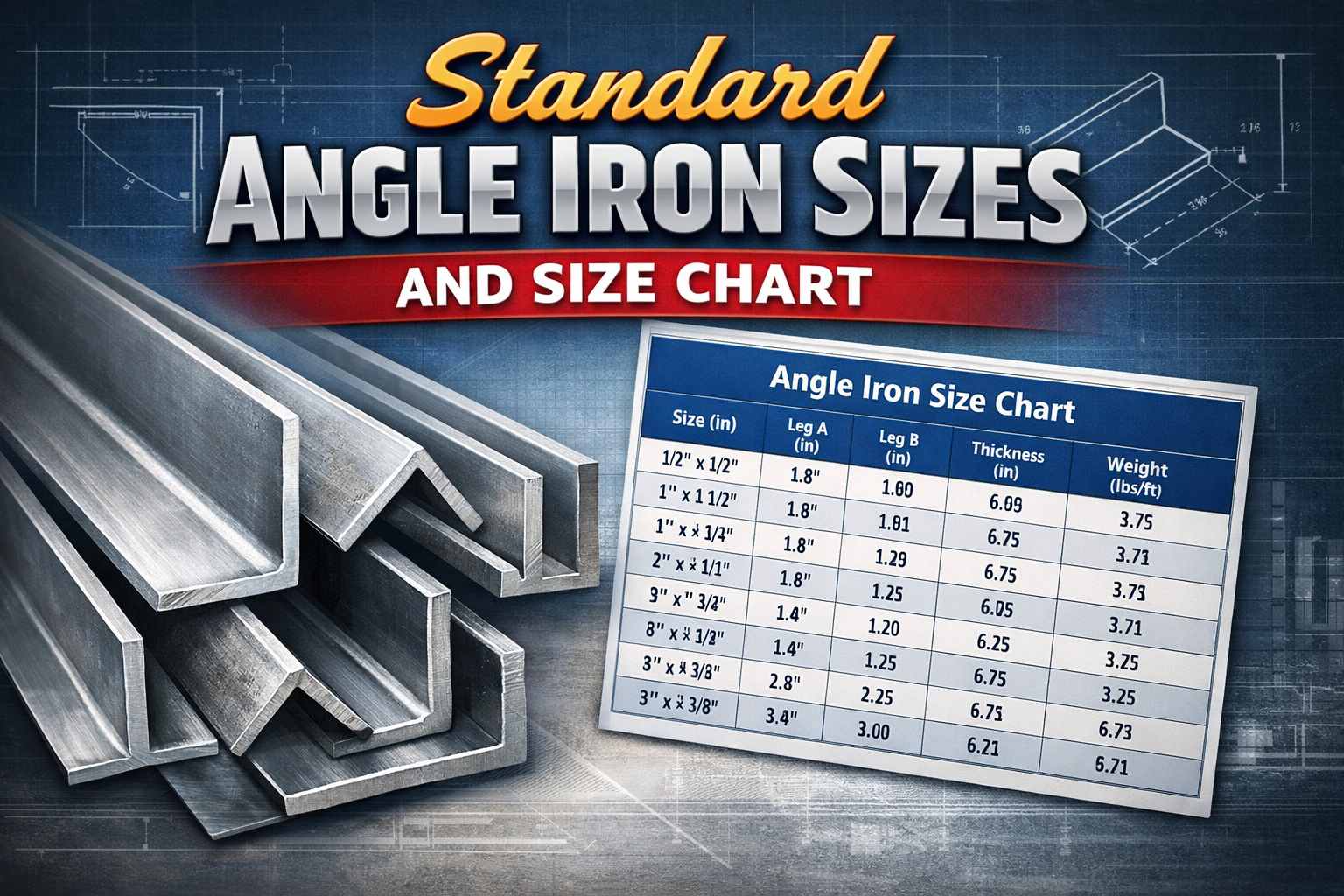

Angle Iron Sizes Chart (Equal Angles)

Here's a chart with common equal angle iron sizes and their approximate weights.

Size (mm) | Thickness (mm) | Approx. Weight (kg/m) |

25x25 | 3 | 1.12 |

30x30 | 3 | 1.36 |

40x40 | 4 | 2.42 |

50x50 | 5 | 3.77 |

60x60 | 6 | 5.42 |

65x65 | 6 | 5.91 |

70x70 | 6 | 6.38 |

75x75 | 6 | 6.85 |

80x80 | 8 | 9.66 |

90x90 | 8 | 10.9 |

100x100 | 10 | 15.1 |

125x125 | 10 | 19.1 |

150x150 | 12 | 27.3 |

The real weight might be a bit different because of how it's made (following ASTM, EN, or JIS rules).

Standard Unequal Angle Iron Sizes

Unequal angles are often used when loads aren't spread evenly or connections need to be different.

Size (mm) | Thickness (mm) | Approx. Weight (kg/m) |

50x30 | 4 | 2.35 |

63x40 | 5 | 3.90 |

75x50 | 6 | 5.69 |

90x60 | 6 | 6.70 |

100x75 | 8 | 10.6 |

125x75 | 8 | 12.1 |

150x90 | 10 | 18.2 |

Common Uses for Different Angle Iron Sizes

Angle Iron Size | Typical Applications |

25–40 mm | Brackets, furniture frames, light fabrication |

50–75 mm | Gates, racks, shelving, small structures |

80–100 mm | Building frames, machinery supports |

25–150 mm | Bridges, towers, heavy structural work |

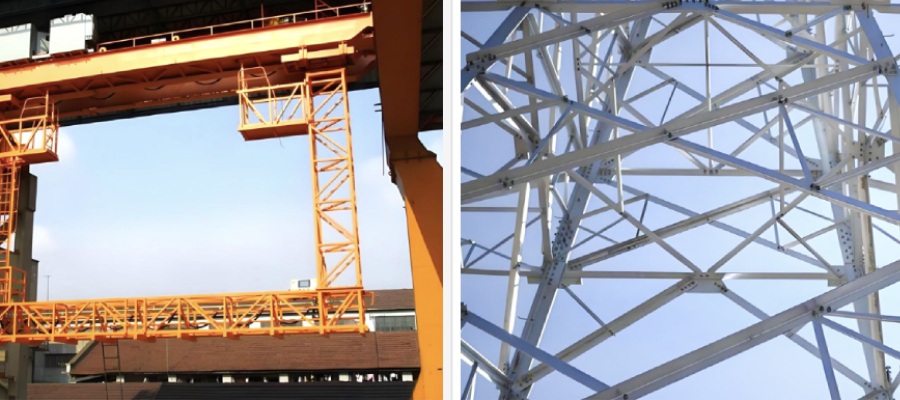

Angle iron is widely used in:

Steel structures

Transmission towers

Equipment frames

Roofing supports

Truck bodies and trailers

How to Choose the Right Angle Iron Sizes

When you're picking out angle iron, here's what to keep in mind:

✅ How much weight will it hold?

If it's holding a lot, you'll need thicker, bigger pieces of angle iron.

✅ How long is the span and what's the structure like?

For longer spans or spots that have a lot of stress, go with larger angles.

✅ How will things be connected?

Bolting or welding might mean you need a certain thickness.

✅ Where will it be located?

If it's outside or near the coast, use galvanized angle iron.

✅ Does it meet the rules?

Make sure it follows ASTM A36, EN 10056, or whatever standards are used where you are.

Quick Tip:

For basic stuff and light building, 40×40 mm to 75×75 mm angles usually work. For bigger building jobs, it's common to use 90×90 mm and up.

FAQs About Angle Iron Sizes

Q: What are some common sizes for steel angle?

A: You'll often see sizes like 50×50×5 mm, 63×63×6 mm, and 75×75×6 mm in building and making things.

Q: What's the difference between equal and unequal angle iron?

A: Equal angle iron has sides that are the same length. Unequal angle iron is used when you need different sides to handle different amounts of weight.

Q: What is angle iron made of?

A: Usually, it's made of mild steel (like Q235 or ASTM A36). But you can also find it in stainless steel and galvanized steel.

Q: Can angle iron be galvanized?

A: Yep. If it's galvanized, it holds up real well against rust, so it's great for using outside.

Knowing your angle iron sizes, checking out a chart, and picking the right ones are super important for building stuff safely and without wasting materials. If you're doing small projects, go with smaller angle irons. For bigger, heavy-duty builds, you'll need the thicker ones. Getting this right means your structure will last longer, cost less in the long run, and stay strong.