Seamless Steel Pipe vs Welded Pipe: Key Differences Explained

Steel pipes are fundamental components in various industries, from construction and oil & gas to water supply and manufacturing. Choosing the right type of steel pipe is crucial for ensuring durability, efficiency, and cost-effectiveness. This guide breaks down the key differences between seamless steel pipes and welded steel pipes, helping engineers, contractors, and procurement specialists make informed decisions.

What Are Seamless and Welded Steel Pipes?

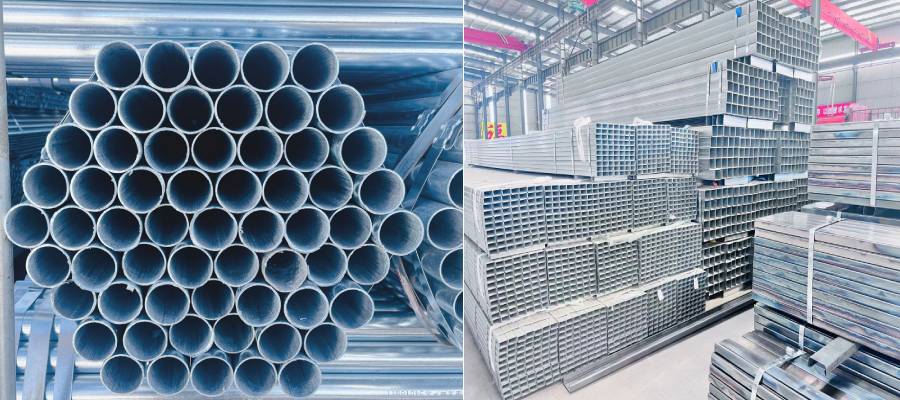

Seamless Steel Pipe

Seamless steel pipes are manufactured from a solid steel billet, which is heated and stretched over a mandrel to create a hollow tube. Since they have no welded joints, seamless pipes are known for their uniform strength, high pressure tolerance, and smooth internal surface.

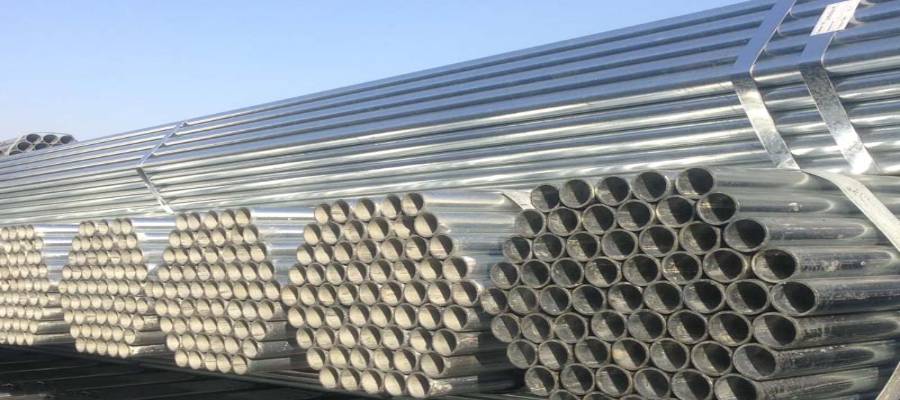

Welded Steel Pipe

Welded steel pipes are made by rolling a flat steel plate or strip into a cylindrical shape and then welding the seam either by electric resistance welding (ERW), submerged arc welding (SAW), or other welding techniques. Welded pipes are often more cost-effective and are widely used in applications where high pressure resistance is not critical.

Key Differences Between Seamless and Welded Steel Pipes

FeatureSeamless Steel PipeWelded Steel PipeManufacturing ProcessExtruded from solid billet, no seamRolled and welded from steel plates/stripsStrength & Pressure ToleranceHigh, suitable for high-pressure applicationsModerate, may be less suitable for extreme pressuresSurface FinishSmooth internal and external surfaceSlightly uneven at weld seam; internal surface may require finishingCostGenerally more expensive due to complex productionMore affordable and faster to produceDimensional AccuracyVery preciseSlightly less precise, depending on welding processApplicationsOil & gas pipelines, boilers, high-pressure hydraulic systemsWater pipelines, structural tubes, low-pressure applications

Common Sizes and Specifications

Steel pipes are available in a wide range of diameters and wall thicknesses, measured in inches or millimeters. Some common categories include:

Small-diameter pipes: 1/2" to 4" – widely used for plumbing, gas lines, and industrial applications

Medium-diameter pipes: 4" to 12" – used for structural frameworks, water distribution, and moderate-pressure pipelines

Large-diameter pipes: 12"+ – typically for oil & gas transmission, sewage, and high-capacity industrial use

Wall thickness is critical for determining pressure handling and load-bearing capacity. Seamless pipes are often preferred when wall uniformity is essential.

Applications of Seamless vs Welded Pipes

Seamless Steel Pipe

High-pressure oil and gas pipelines

Boilers and heat exchangers

Hydraulic systems

Industrial machinery

Welded Steel Pipe

Structural supports in buildings and bridges

Water and sewage pipelines

Low-pressure oil and gas lines

Mechanical and furniture tubing

How to Choose Between Seamless and Welded Pipes

Consider these factors when selecting the right steel pipe type:

✅ Pressure Requirements – For high-pressure applications, seamless pipes are recommended.

✅ Cost Efficiency – Welded pipes are more economical for lower-pressure or structural applications.

✅ Dimensional Accuracy – Seamless pipes offer tighter tolerances for critical systems.

✅ Project Size – Large-scale industrial pipelines may require seamless pipes for safety; structural frameworks can rely on welded pipes.

✅ Corrosion Resistance – Both pipes can be galvanized or coated; seamless pipes may have a slight advantage in uniformity of coating adhesion.

Pro Tip: For most commercial construction projects, welded pipes suffice, while high-pressure industrial or oilfield projects demand seamless pipes.

FAQs About Seamless and Welded Steel Pipes

Q: Can welded pipes handle high pressure like seamless pipes?

A: Welded pipes can handle moderate pressures, but seamless pipes are superior for very high-pressure systems due to the absence of a seam.

Q: Are seamless pipes more expensive?

A: Yes, seamless pipes cost more due to the complex manufacturing process, but they provide higher strength and reliability.

Q: Can both types be galvanized?

A: Yes, both seamless and welded pipes can be galvanized to resist corrosion.

Q: Which pipe is better for structural use?

A: Welded pipes are generally sufficient for structural purposes unless extreme loads or pressures are involved.

Conclusion

Choosing the right type of steel pipe is crucial for both structural integrity and cost-effectiveness. Seamless steel pipes provide superior strength, uniformity, and pressure tolerance, making them ideal for high-demand applications. Welded steel pipes are more economical and suitable for structural and low-pressure uses. By understanding the differences, engineers and contractors can select the optimal pipe type for their specific project requirements.