GI Pipe: Meaning, Full Form, Specifications & Weight Guide

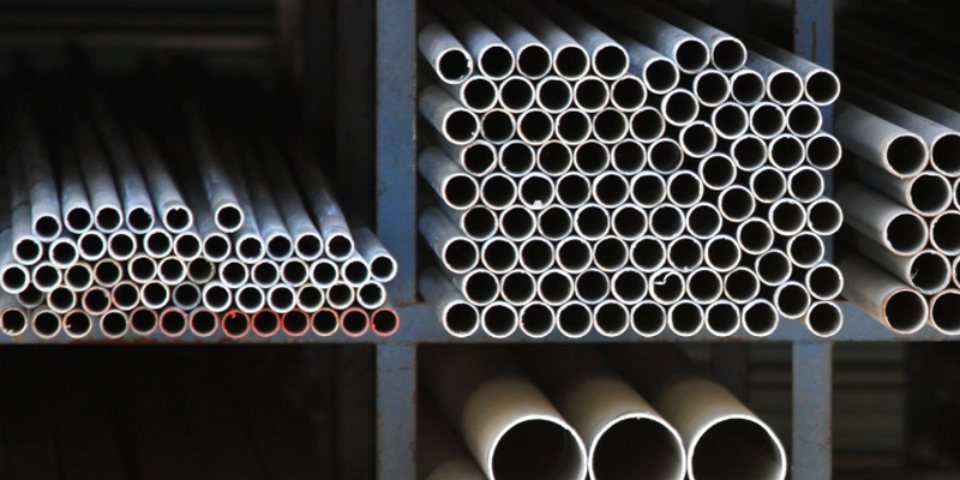

GI Pipe (Galvanized Iron Pipe) is one of the most widely used piping materials in construction, water supply, fire protection, and industrial systems. Its corrosion-resistant zinc coating, long service life, and cost-effectiveness make it a preferred choice for engineers, contractors, and infrastructure developers.

This guide explains what GI pipe is, its full form, specifications, sizes, weights, and key applications—helping you choose the right product for your project.

What Is GI Pipe?

GI Pipe stands for Galvanized Iron Pipe.

It is a steel pipe coated with a protective layer of zinc to prevent corrosion and rust. The zinc coating is applied through the hot-dip galvanizing process, forming a strong barrier against moisture, chemicals, and environmental exposure. Galvanized steel pipes can be divided into two types: round and square pipes

GI Pipe Meaning

The term refers to:

A steel pipe treated with a galvanized zinc layer

A pipe designed for corrosion resistance and extended durability

A commonly used pipe in water lines, structural applications, and outdoor installations

Full Form of GI Pipe

GI Pipe = Galvanized Iron Pipe

GI Pipe Specifications

GI pipes follow international standards such as:

IS 1239 (Part 1 & 2) – India standard for medium & heavy pipes

BS 1387 – British Standard for galvanized welded steel pipes

ASTM A53 / A123 – American standards for galvanized steel pipes

EN 10255 / EN 10240 – European standard for galvanized pipe and coating

Most GI pipes are classified by:

Nominal Bore (NB) – the internal diameter

Outside Diameter (OD)

Wall Thickness

Class (Light, Medium, Heavy)

GI Pipe Classifications (Common Grades)

Class | Typical Marking | Wall Thickness | Application |

ClassA (Light) | Blue | Thin | Low-pressure water, fencing |

ClassB (Medium) | Yellow | Medium | Water supply, plumbing |

ClassC (Heavy) | Red | Thick | Firefighting,high pressure, industrial |

GI Pipe Weight Chart (per meter)

Weight depends on:

Pipe diameter

Wall thickness

Steel density

Below is a typical GI pipe weight chart for Class B (medium class):

Size (NB) | Thickness | Weight (kg/m) |

15mm | 2.65mm | 1.38kg |

20mm | 2.65mm | 1.84kg |

25mm | 3.25mm | 2.59kg |

32mm | 3.25mm | 3.38kg |

40mm | 3.25mm | 4.08kg |

50mm | 3.65mm | 5.47kg |

60mm | 3.65mm | 7.48kg |

80mm | 4.05mm | 9.78kg |

100mm | 4.50mm | 13.43kg |

If you need a full detailed weight chart for all classes (A/B/C), I can generate it.

Need GI Pipes?

Shineyond Group supplies:

GI Pipe / Galvanized Pipe

Galvanized Steel Tubes

Steel Coils, Sheets, Pipe, Rebar & Sections

Factory-direct prices, bulk supply, full specifications available.

Contact us for a quote today!

Common Uses of GI Pipe

GI pipes are used across residential, commercial, and industrial applications:

1. Water Supply Systems

✔ Plumbing lines

✔ Rural & municipal water transport

✔ Borewell and overhead tank installation

2. Firefighting & High-Pressure Systems

✔ Fire hydrant networks

✔ Sprinkler systems

3. Construction & Structural Uses

✔ Scaffolding

✔ Handrails, fences, gates

✔ Greenhouse structures

4. Industrial Applications

✔ Oil & gas transport

✔ Chemical lines (non-corrosive fluids)

✔ Compressed air piping

5. Agriculture

✔ Irrigation lines

✔ Tube wells

✔ Drip and sprinkler systems

How to Choose the Right GI Pipe

Consider the following factors:

1. Pressure Requirements

Low pressure → Class A

Medium pressure → Class B

High pressure & industrial → Class C

2. Corrosion Resistance Needed

Higher zinc coating = longer pipe life.

3. Pipe Size & Flow Rate

Bigger diameter = higher flow capacity.

4. Standards & Certification

Always ensure compliance with:

IS 1239

BS 1387

ASTM A53

5. Application Environment

Outdoor, chemical exposure, or load-bearing use requires heavier and better-coated pipes.

FAQs About GI Pipes

Q1: What is the full form of GI pipe?

A: Galvanized Iron Pipe.

Q2: What is the meaning of GI pipe?

A zinc-coated steel pipe designed to resist corrosion.

Q3: Are GI pipes rust-proof?

They are rust-resistant, not completely rust-proof. Over time, zinc layers can wear out.

Q4: Is GI pipe suitable for drinking water?

Yes, but ensure certified pipes with safe zinc coating thickness.

Q5: What is better: GI pipe or MS pipe?

GI pipes are better for corrosion-prone or outdoor environments, while MS pipes suit structural or welding applications.