Galvanized Steel Pipe | GI Pipe Manufacturer & Supplier

WhatsApp / Tel / Wechat

Still deciding? Get samples first, Contact US !

- Product Description

-

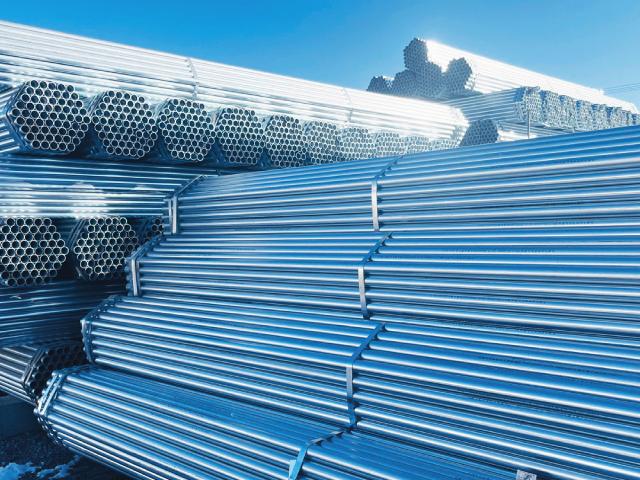

Galvanized Steel Pipe is a carbon steel pipe coated with a protective zinc layer to prevent rust and corrosion. It is widely used in construction, water supply systems, fencing, scaffolding, and industrial applications, especially in humid or outdoor environments.

At Shineyond Group, we supply premium gi pipes manufactured to international standards, ensuring long service life, stable performance, and competitive pricing for global buyers.

Galvanized Steel Pipe Parameters

Product name Galvanized steel pipe Thickness 0.12mm-60mm or customer requirements Diameter 10-3000mm or customer requirements Length 5m-14m, 5.8m, 6m, 10m-12m, 12m or according to customer's actual requirements Technology ERW welding, hot dip galvanizing, pregalvanizing Galvanized pre-galvanized steel pipe: 30g/m2-80g/m2 Galvanized steel pipe: 200g/m2-400g/m2 Surface treatment Galvanized, oiled, unoiled, lacquered, etc. Materials 10#, 20#, 45#, 16Mn, A53(A, B), Q235, q345, Q195, Q215, St37, St42, ST37-2, St35.4, St52.4, ST35, etc. Pipe ends flat/beveled, protected by plastic covers at both ends, cut square, slotted, threaded and coupler, etc. Standards ASTM AISI JIS DNS GB, etc Package Factory standard export seaworthy packing Application 1. Fence, greenhouse, door tube, greenhouse2. Low pressure liquid, water, gas, oil, pipeline pipe3. Suitable for indoor and outdoor construction4. Widely used in scaffolding construction, low cost and convenient GI Pipe Key Features & Advantages

Hot-Dip Galvanized Surface – Strong corrosion and rust resistance

High Mechanical Strength – Suitable for structural and pressure use

Uniform Zinc Coating – Long service life

Smooth Inner Surface – Efficient fluid flow

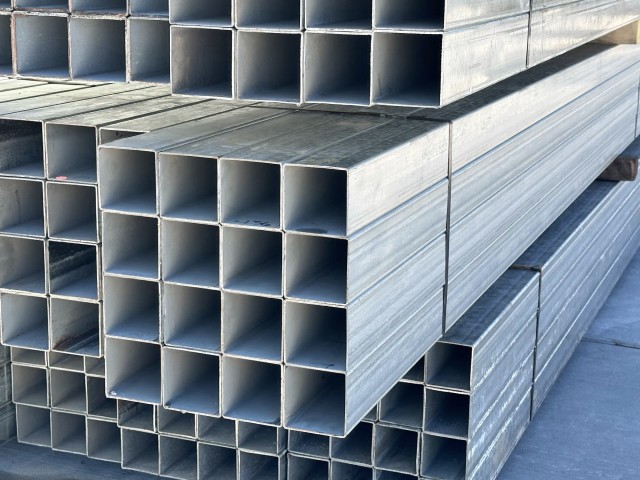

Wide Size Range – Round, square, and rectangular pipes available

Low Maintenance Cost – Ideal for long-term projects

Applications of GI Pipe

Gi pipes are commonly used in:

Construction & Steel Structure Projects

Water Supply & Drainage Systems

Fencing, Handrails & Guardrails

Scaffolding & Temporary Structures

Fire Protection Systems

Agricultural & Greenhouse Structures

They are especially suitable for infrastructure and housing projects in Africa and developing markets, where durability and cost efficiency are essential.

GI Pipe Manufacturing Process

High-quality steel strip forming

High-frequency welding

Surface cleaning & degreasing

Hot-dip galvanizing or pre-galvanizing

Quality inspection & packaging

Each pipe undergoes strict dimensional, coating thickness, and surface quality checks before shipment.

Why Choose Our Galvanized Steel Pipe

As a professional gi pipe supplier, Shineyond Group provides reliable galvanized steel pipes to customers worldwide.

Strict quality inspection and stable supply

Competitive factory-direct pricing

Export-standard packaging

Fast delivery and professional technical support

We understand the needs of contractors, distributors, and project buyers, providing practical solutions rather than just products.

For construction and infrastructure projects, many clients prefer square or rectangular galvanized steel pipes due to their superior structural stability.

Explore our Galvanized Square Steel Pipe and Galvanized Rectangular Steel Pipe solutions for engineering applications.

FAQ – Galvanized Steel Pipe

Q1: What is galvanized steel pipe used for?

It is widely used in construction, water pipelines, fencing, scaffolding, and industrial applications.

Q2: What is the difference between hot-dip and pre-galvanized steel pipes?

Hot-dip galvanized pipes have thicker zinc coating and better corrosion resistance, making them more suitable for outdoor use.

Q3: Can galvanized steel pipes be welded?

Yes, but proper ventilation and anti-corrosion treatment after welding are recommended.

Looking for a reliable Galvanized Steel Pipe supplier?

Contact Shineyond Group today for competitive pricing, technical support, and fast global delivery.

Galvanized Steel Pipe | GI Pipe Manufacturer & Supplier

WhatsApp / Tel / Wechat

Contact us via email

Still deciding? Get samples first, Contact US !

Products Category

Tag list

Galvanized steel pipe

Galvanized round steel pipe

Hot dipped galvanized steel pipe

GI steel pipe

Galvanized iron pipe

Sliver square steel pipe

Hot dipped galvanized square steel pipe

GI square steel pipe

Galvanized Round Steel Pipe

Get a Free Quote

Note: Please leave your email address, our professionals will contact you as soon as possible!