What is Strip Steel and How to Choose the Right One?

Strip steel is one of the most versatile steel forms, widely used across industries such as construction, automotive manufacturing, electronics, and even scientific or medical engineering. Understanding what strip steel is, its production process, properties, and applications can help businesses and engineers select the right material for their projects. This article will guide you through everything you need to know about strip steel and how to choose the most suitable option.

What is Strip Steel?

Strip steel is a bulk steel material manufactured primarily for small steel components. Unlike large steel plates, strip steel is narrower and thinner, usually less than 24 inches (60.96 cm) in width and 0.157–0.197 inches (4–5 mm) in thickness. Manufacturers typically supply it in large coils, which are then cut or processed into smaller strips for specific applications.

Its compact size and high versatility make strip steel ideal for projects requiring precision and smaller steel pieces. Common uses include automotive parts, electronic components, household appliances, and structural elements in construction.

Strip Steel Production Process

The production of strip steel involves several precise steps to ensure high quality and performance:

Step 1: Smelting and Alloying

Steel mills begin by smelting iron ore at extremely high temperatures, sometimes exceeding 2,000°C. Other metals and chemical elements are added to create the desired steel alloy, tailored to specific mechanical or chemical requirements.

Step 2: Rolling

The molten steel is cast into slabs and then rolled using hot or cold rolling methods. Hot rolling thins the steel while removing surface imperfections, producing flat, long, or striped shapes. Cold rolling further refines thickness, improves surface finish, and enhances mechanical properties.

Step 3: Surface Treatment

After rolling, steel may undergo technical treatments such as:

Acid pickling to remove oxides and impurities

Coating for corrosion resistance

Heat treatment to improve strength and hardness

Anti-oxidation surface treatments

These processes ensure that strip steel meets the stringent quality standards required for industrial applications.

Step 4: Roll Slitting

Finally, the large coils are processed through roll slitting, which cuts them into narrower strips. Depending on project requirements, widths as small as 0.035 inches can be achieved.

Outstanding Properties of Strip Steel

Strip steel is usually derived from hot-rolled or cold-rolled coils, inheriting several advantages:

High Strength and Durability: Hot-rolled strips maintain excellent mechanical properties.

Precision Thickness: Cold-rolled strips offer tighter thickness tolerances and smooth surfaces.

Versatility: Strip steel can be further processed into complex components, making it suitable for various applications.

Corrosion Resistance: With proper surface treatments, strip steel can withstand harsh environments.

These features make strip steel a preferred choice for both industrial and commercial applications.

Applications of Strip Steel

Strip steel is highly adaptable, and its applications span multiple industries:

Automotive Industry

Cold-rolled stainless steel strips are commonly used to manufacture automotive parts. The strips can be stamped, rolled, and shaped into components such as brackets, chassis reinforcements, and decorative trims. Their uniform thickness and smooth surface make assembly and construction easier.

Construction

In building and structural applications, stainless steel and coated steel strips are used for reinforcing, cladding, and decorative purposes. Hot-rolled strips provide cost-effective structural support, while cold-rolled strips offer enhanced aesthetics for visible applications.

Electronics

Stainless steel strips are ideal for electronic components because of their excellent thermodynamic properties, such as heat conduction, capacity, and resistance to high temperatures. They are widely used in appliances like refrigerators, air conditioners, and other electrical devices.

Household Appliances

Manufacturers use strip steel to produce durable parts for washing machines, ovens, microwaves, and other home appliances. Its strength, corrosion resistance, and ability to be fabricated into precise shapes make it highly suitable for these applications.

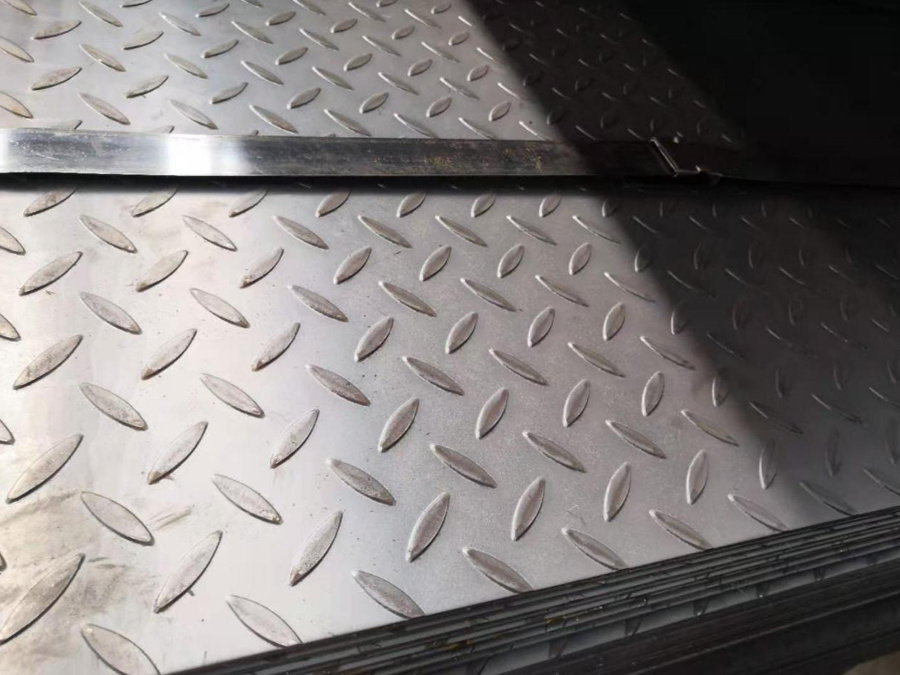

Strip Steel vs. Sheet Steel

Though strip steel and sheet steel are both derived from flat-rolled coils, they differ in size and application.

Sheet Steel

Thickness: Less than ¼ inch

Width: More than 24 inches

Processed for structural applications or large panels

Often undergoes pickling, coating, annealing, and heat treatment

Used for large projects, construction panels, and structural components

Strip Steel

Thickness: Similar to sheet steel but narrower width (<24 inches)

Lightweight, easy to transport, process, and assemble

Suitable for small parts and detailed components

Cut from large coils using roll slitting

The key distinction is the width: products narrower than 24 inches are classified as strip steel, while wider products are considered sheets.

How to Choose the Right Strip Steel

Selecting the proper strip steel depends on your project requirements and desired properties. Consider the following factors:

1. Rolling Method

Hot-rolled strips: Lower cost, rough surface, suitable for structural use

Cold-rolled strips: Smooth, precise surface, ideal for visible or aesthetic applications

2. Material Type

Stainless Steel: Offers corrosion resistance, ideal for electronics, automotive, and appliances

Carbon Steel: Economical choice for structural components and construction projects

Aluminum Alloy Strips: Lightweight and corrosion-resistant, used for lightweight structures

3. Thickness and Width

Determine the required mechanical strength and flexibility

Ensure the width fits the cutting or stamping equipment

4. Surface Treatment

Coated or polished strips may be required for corrosion resistance or aesthetic purposes

Acid-pickled strips have improved bonding and finishing quality

5. Application Needs

Automotive and electronics require high precision and tight tolerances

Construction and structural projects can prioritize cost and strength

By carefully evaluating these factors, you can select the right strip steel for your needs, ensuring efficiency, durability, and long-term performance.

Strip steel is a versatile, essential material in modern manufacturing, offering strength, durability, and adaptability for numerous industries. From automotive parts to construction components and electronic devices, strip steel provides the ideal balance between size, quality, and cost. Understanding its production, properties, and differences from sheet steel ensures informed decisions when selecting materials for your projects.

Whether you are sourcing hot-rolled, cold-rolled, stainless, or aluminum strip steel, prioritizing the right width, thickness, material type, and surface treatment will guarantee optimal performance and value for your applications.