Steel Strip (Cold Rolled & Galvanized) | Precision Steel

WhatsApp / Tel / Wechat

Still deciding? Get samples first, Contact US !

View similar products

- Product Description

-

What Is Steel Strip?

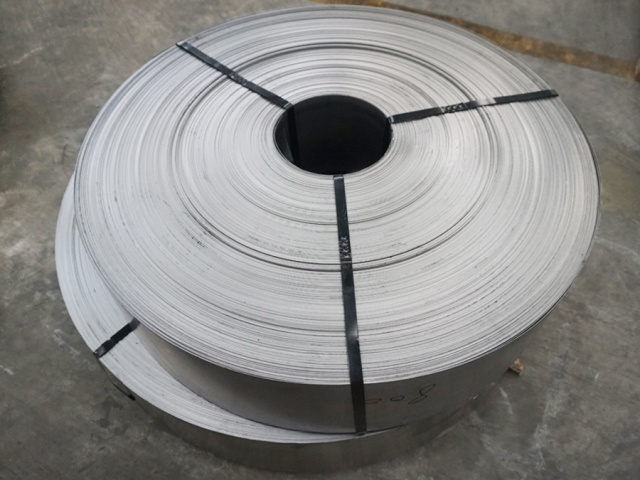

Steel strip refers to steel processed into narrow widths from steel coils through slitting or rolling. It offers excellent dimensional accuracy, smooth surface quality, and consistent mechanical performance.

At Shineyond Group, steel strips are produced and supplied to meet international manufacturing standards, ensuring reliable performance for downstream processing.

Steel Strip Specifications

Material

carbon steel, carbon bonded steel, spring steel, tool steel, and other steel production

Grade

Q195 Q235 Q355 Q215 SS400 SPHC sae006 sae008 SPHD

Standard

Bs EN GB AiSi ASTM DIN JIS

Width:

20mm-1000mm

Thickness

hot rolled ordinary strip thickness of 2mm-6mm,

cold rolled strip is generally 0.05mm - 3.60mm.

Weight:

3-5tons

MOQ

None

Delivery Time

in stock

Packaging:

Packing belt,binding

Types of Steel Strip

Shineyond Group supplies multiple types of strip steel to meet different industrial needs:

Cold Rolled strip steel – smooth surface, high dimensional accuracy

Galvanized Steel Strips – zinc-coated for corrosion resistance

Hot Rolled Strip Steel Coil – cost-effective solution for structural and industrial use

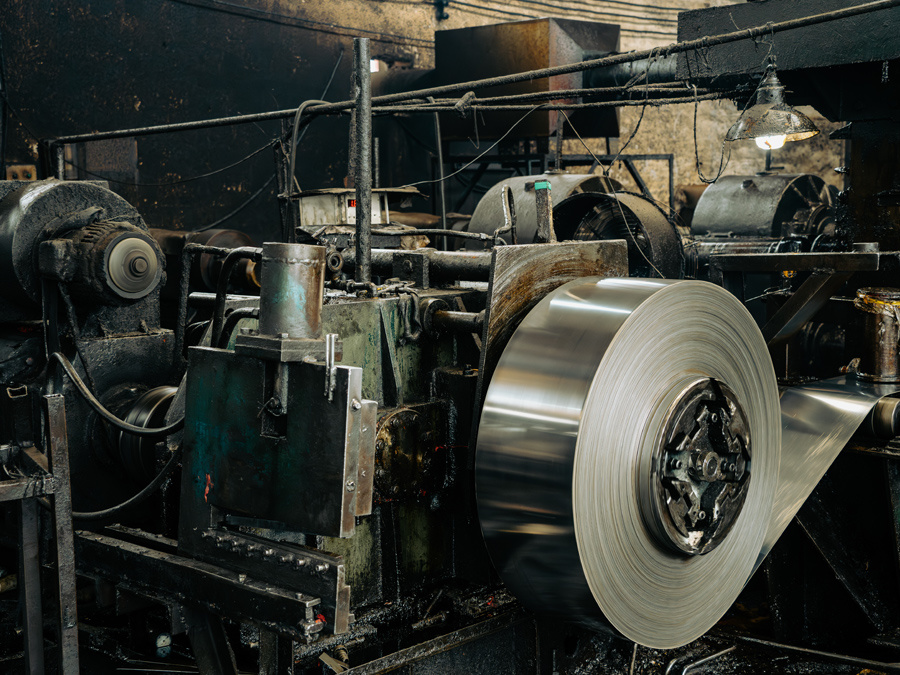

Strip Steel Process

Cold rolled strip process:

pickling -- rolling -- annealing -- synchronous lubrication of rolling size -- anti-rust oil -- leveling and sizing -- polishing -- packaging

Hot rolled strip process:

Heating furnace - phosphorus removal machine - roughing mill - phosphorus removal machine - finishing mill - Surface quality inspection instrument layer cold - coiler - bundling machine - spray mark machine - coil store slab

The slab is heated to the desired rolling temperature, removing surface oxides through a rough rolling mill. The width and thickness of the steel strips are adjusted in rough and finishing mills, and the surface temperature is strictly controlled during cooling. Finally, the strips are wound, numbered, and packaged into finished steel strips.

Advantages:steel strips is generally supplied in coils, with high dimensional accuracy, good surface quality, easy processing, material saving and other advantages.

Key Features & Advantages of Strip Steel

Precise thickness and width tolerance

Smooth and uniform surface quality

Good formability and machinability

Stable mechanical properties

Suitable for high-speed production lines

Custom specifications available from Shineyond Group

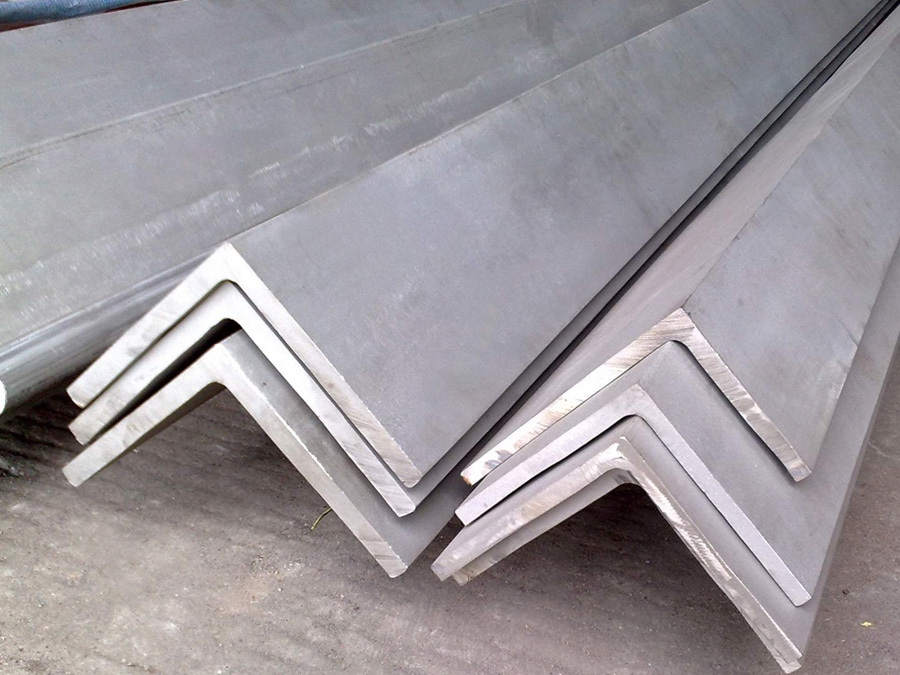

Applications of Strip Steel

Strips steel from Shineyond Group are widely used in:

Steel pipe and tube manufacturing

Automotive components and stamping parts

Household appliances

Construction profiles and frames

Electrical and industrial equipment

Metal packaging and fastening systems

Why Choose Shineyond Group

Stable quality with strict tolerance control

Wide range of steel grades and coatings

Export-standard packing for global delivery

Reliable supply for long-term projects

Professional technical support for industrial buyers

FAQ – Strip Steel

Q1: What is steel strip mainly used for?

Steel strip is widely used for pipe making, stamping, forming, and industrial manufacturing.

Q2: What is the difference between steel strip and steel coil?

Steel strip is narrower and processed from steel coil through slitting or rolling.

Q3: Can Shineyond Group customize steel strip specifications?

Yes, thickness, width, surface finish, and coating can all be customized.

Steel Strip (Cold Rolled & Galvanized) | Precision Steel

WhatsApp / Tel / Wechat

Contact us via email

Still deciding? Get samples first, Contact US !

Products Category

Tag list

Steel strip

Galvanized steel strip

Spring steel strip

Steel strip coil

Cold rolled steel strips

Carbon steel strip

Get a Free Quote

Note: Please leave your email address, our professionals will contact you as soon as possible!