Galvanized Square Steel Tube: Advantages, Uses & Specs

Galvanized steel square tube, also known as galvanized square steel tube, is one of the most widely used structural steel products in construction, infrastructure, and industrial fabrication. Thanks to its excellent corrosion resistance, high strength, and long service life, it has become a preferred choice for both indoor and outdoor applications.

This guide provides a complete overview of galvanized square tubes, including specifications, manufacturing processes, applications, advantages, and key considerations when sourcing from suppliers.

What Is a Galvanized Steel Square Tube?

A galvanized steel square tube is a hollow structural steel tube with a square cross-section that has been coated with zinc to protect it from corrosion. The zinc layer acts as a barrier against moisture, oxygen, and harsh environments, significantly extending the steel’s lifespan.

The term galvanized square steel tube is often used interchangeably in international trade and technical documents, referring to the same product.

Manufacturing Process of Galvanized Square Steel Tubes

There are two main galvanizing methods used in production:

Hot-Dip Galvanized Square Tube

Steel tube is immersed in molten zinc

Thick, durable zinc coating

Ideal for outdoor and heavy-duty applications

Longer corrosion protection life

Pre-Galvanized (GI) Square Tube

Made from galvanized steel strip or coil

Smooth and uniform surface

Cost-effective for indoor or light outdoor use

Hot-dip galvanized steel square tube is generally preferred for infrastructure and construction projects exposed to weather.

Galvanized Square Steel Tube Specifications

Galvanized square tubes are available in a wide range of sizes and thicknesses to meet different structural requirements.

Common Specifications

Size: 20×20 mm to 300×300 mm

Wall Thickness: 0.8 mm – 12.0 mm

Length: 6 m, 12 m, or customized

Zinc Coating: 40–275 g/m²

Standards

ASTM A500 / ASTM A53

EN 10219 / EN 10210

BS 1387

JIS G3466

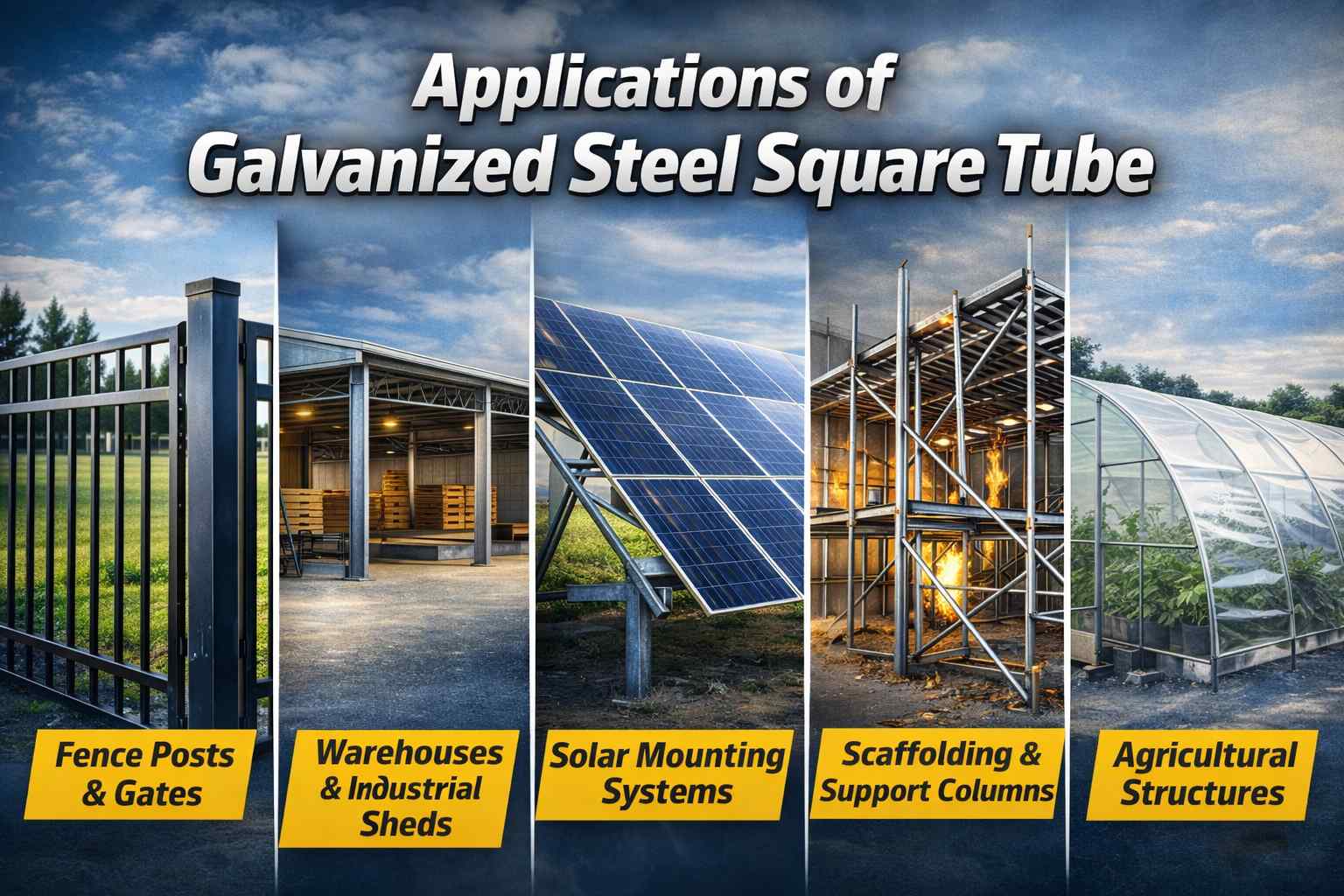

Applications of Galvanized Steel Square Tube

Because of its structural stability and corrosion resistance, galvanized square tube is widely used across multiple industries:

Steel structures and building frames

Warehouses and industrial sheds

Fence posts and gates

Solar mounting systems

Scaffolding and support columns

Agricultural structures and greenhouses

Furniture and metal fabrication

In coastal or high-humidity regions, galvanized square steel tube offers a clear advantage over black steel tubes.

Key Advantages of Galvanized Square Steel Tube

Corrosion Resistance – Zinc coating protects against rust and oxidation

Long Service Life – Lower maintenance cost over time

High Strength-to-Weight Ratio – Strong yet lightweight

Easy Fabrication – Suitable for welding, cutting, and drilling

Cost-Effective – Reduced replacement and repair costs

These benefits make galvanized steel square tubes especially popular in large-scale construction projects.

Galvanized Steel Square Tube vs Black Square Tube

Feature | Galvanized Square Tube | Black Square Tube |

Corrosion Resistance | High | Low |

Surface Treatment | Zinc Coated | None |

Outdoor Use | Suitable | Limited |

Maintenance Cost | Low | High |

Initial Cost | Slightly Higher | Lower |

For long-term outdoor use, galvanized square steel tube is the more economical choice.

How to Choose the Right Galvanized Square Steel Tube Supplier

When sourcing galvanized steel square tubes for export or construction projects, consider the following factors:

Compliance with international standards

Consistent zinc coating thickness

Stable mechanical properties

Custom size and length capability

Export packaging and logistics experience

Reliable suppliers should provide mill test certificates (MTC) and support bulk orders.

Frequently Asked Questions (FAQ)

Is galvanized steel square tube suitable for outdoor use?

Yes. Especially hot-dip galvanized square tubes are designed for long-term outdoor exposure.

Can galvanized square steel tube be welded?

Yes, but proper ventilation and post-weld zinc treatment are recommended.

What is the difference between galvanized steel square tube and galvanized rectangular tube?

Square tubes have equal sides, while rectangular tubes have different width and height.

Conclusion

Galvanized steel square tube and galvanized square steel tube are essential materials for modern construction and industrial projects. With excellent corrosion resistance, structural reliability, and cost efficiency, they remain a top choice for global buyers in 2026 and beyond.

Choosing the right specifications and a reliable supplier ensures project durability and long-term value.