What Is a Structural Channel? A Complete Guide for Builders and Engineers

In steel construction and industrial projects, channel-shaped steel sections are widely used for load-bearing and framing purposes. Thanks to their open profile and excellent strength-to-weight ratio, they are commonly selected by builders and engineers for both light and heavy structural applications.

This guide explains the definition, types, sizes, uses, and selection tips of channel steel to help you choose the right solution for your project.

What Is a Structural Channel?

A Structural Channel is a steel section with a C-shaped or U-shaped cross-section, consisting of a vertical web and two parallel flanges extending in the same direction. This design allows efficient load distribution while keeping the section relatively lightweight.

Channel sections are typically produced through hot rolling or cold forming and are widely used as secondary structural members in buildings, bridges, and industrial facilities.

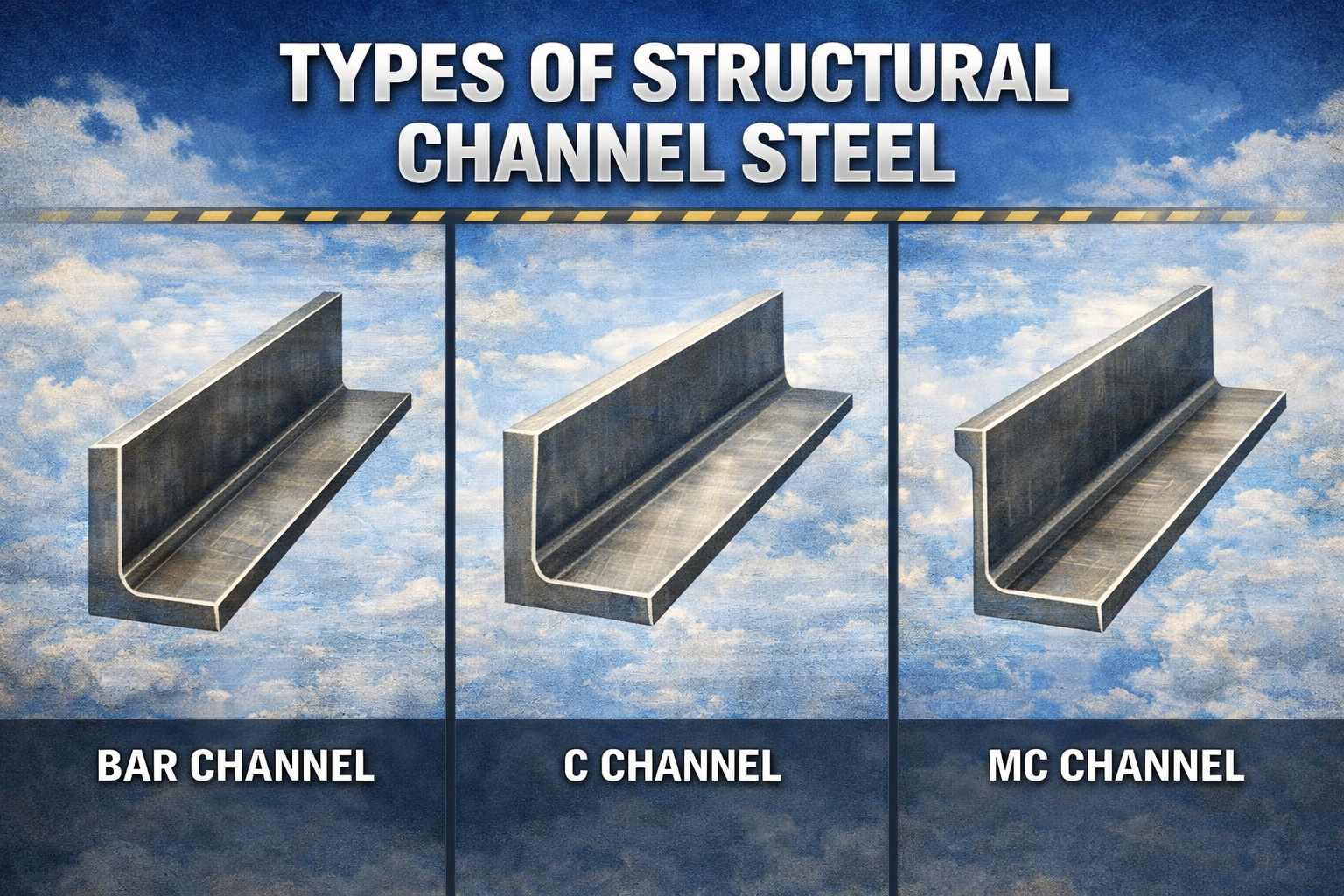

Types of Structural Channel Steel

Structural channel steel is available in several forms, depending on shape and manufacturing method:

C Channel Steel – Uniform thickness and strong bending resistance

U Channel Steel – Deeper web, suitable for load support and framing

Hot-Rolled Channels – High strength for heavy-duty structures

Cold-Formed Channels – Lightweight and precise, often used in prefabricated buildings

Each type serves different structural and economic requirements.

Structural Channel Sizes and Standards

Structural Channel products are manufactured in a wide range of sizes and thicknesses to meet engineering demands. Common standards include:

ASTM (A36, A572)

EN (EN 10279, EN 10025)

JIS (JIS G3192)

GB/T 706

Key size parameters include web height, flange width, thickness, and unit weight. Engineers select dimensions based on load calculations, span length, and design codes.

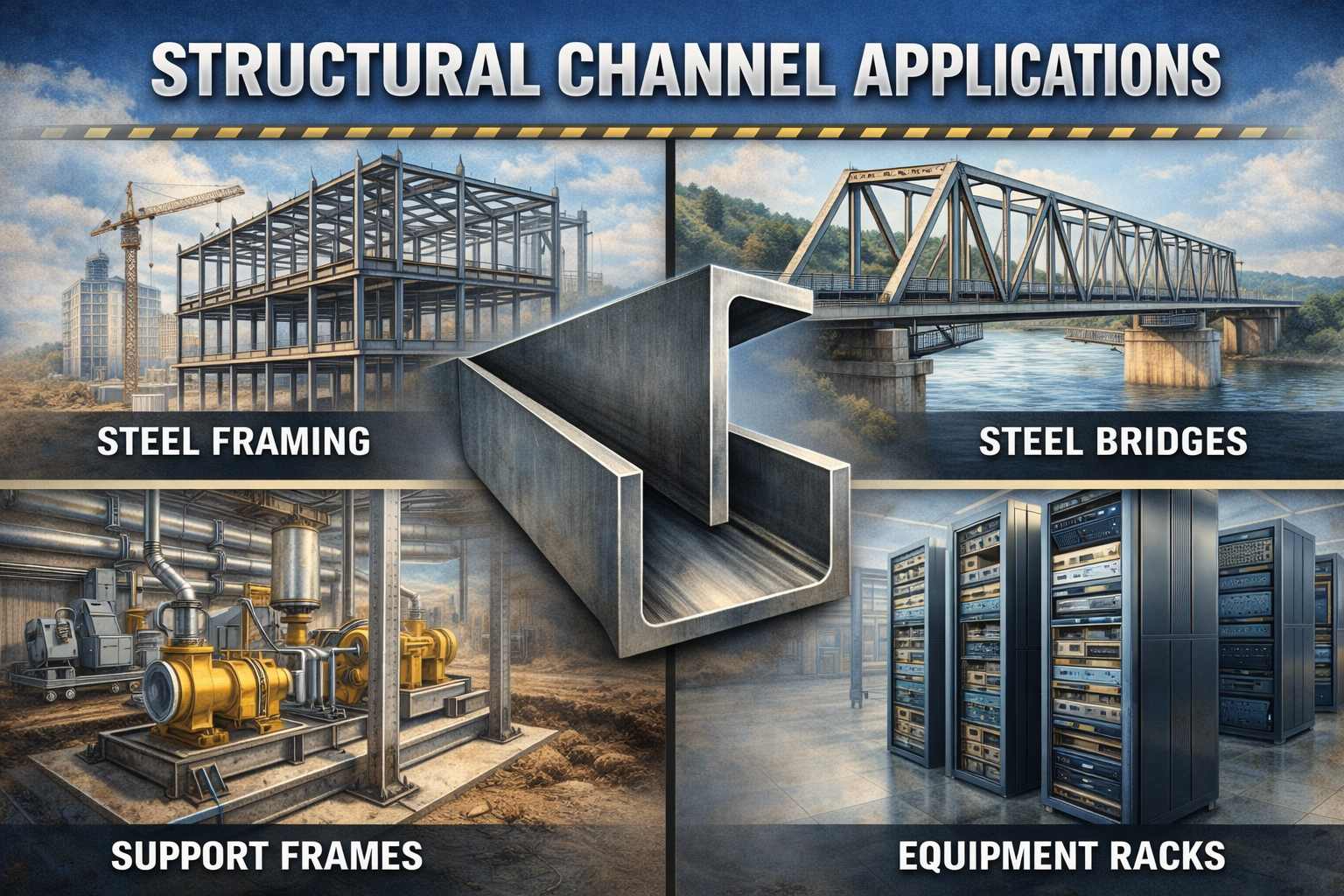

Structural Channel Applications in Construction

Structural Channel sections are widely used across construction and industrial fields, including:

Steel building frames and bracing

Platforms, walkways, and stair structures

Bridge components and supports

Equipment bases and machinery frames

Solar mounting and warehouse systems

Their open profile allows easy welding, bolting, and connection with I beams, H beams, and angle steel.

Advantages of Using Structural Channel Steel

Structural Channel steel offers multiple advantages in engineering projects:

High load-bearing efficiency

Easy fabrication and installation

Cost-effective material usage

Good compatibility with surface treatments such as galvanizing

Flexible use in both permanent and temporary structures

These benefits make channel steel a reliable choice for builders and engineers.

How to Select the Right Structural Channel

When choosing a Structural Channel, consider the following factors:

1. Structural load and design requirements

2. Span length and support conditions

3. Environmental exposure and corrosion risk

4. Compliance with local standards and codes

5. Installation and fabrication methods

Proper selection ensures safety, durability, and cost control throughout the project lifecycle.

Why Choose Shineyond Group for Structural Channel Supply?

Shineyond Group is a professional steel manufacturer and exporter providing high-quality Structural Channel products to international markets. We offer:

Complete C channel and U channel size ranges

Products compliant with ASTM, EN, JIS, and GB standards

Hot-rolled, cold-formed, and galvanized options

Stable quality, competitive pricing, and reliable delivery

Our channel steel solutions are trusted by construction and infrastructure projects worldwide.

Conclusion: Structural Channel in Modern Engineering

Structural Channel steel plays a key role in modern construction by providing strength, flexibility, and efficiency. Understanding its types, sizes, and applications enables builders and engineers to make informed material decisions and achieve long-term structural performance.