Hot Rolled Steel Coil: Overview, Process, and Uses

Hot rolled steel coil is a common steel product used in many industries. It is valued for its strength, good workability, and cost efficiency. Because it is produced at high temperatures, this material is suitable for structural and industrial applications where precise surface finish is not required.

This article introduces its basic definition, production process, main features, and typical uses.

What Is Hot Rolled Steel Coil?

Hot rolled steel coil refers to steel that is rolled at temperatures above its recrystallization point. At such high heat levels, the steel becomes easier to shape and form. After rolling, the steel strip is cooled and wound into coils for storage and transport.

Compared with cold rolled products, this type of steel usually has a rough surface and slightly less accurate dimensions. However, it offers reliable mechanical performance and lower manufacturing cost.

Manufacturing Process

The production process includes several main steps:

Heating: Steel slabs are reheated in a furnace until they reach the required rolling temperature.

Rolling: The heated slabs pass through rolling mills to reduce thickness and control width.

Cooling and coiling: The steel strip is cooled and then coiled into large rolls.

This process improves ductility and makes the material suitable for heavy-duty use.

Main Characteristics

This steel product has several important characteristics:

Good strength and toughness

Easy cutting, bending, and welding

Cost-effective for large-volume projects

Natural mill scale on the surface

Because of these properties, it is widely used where appearance is not a top priority.

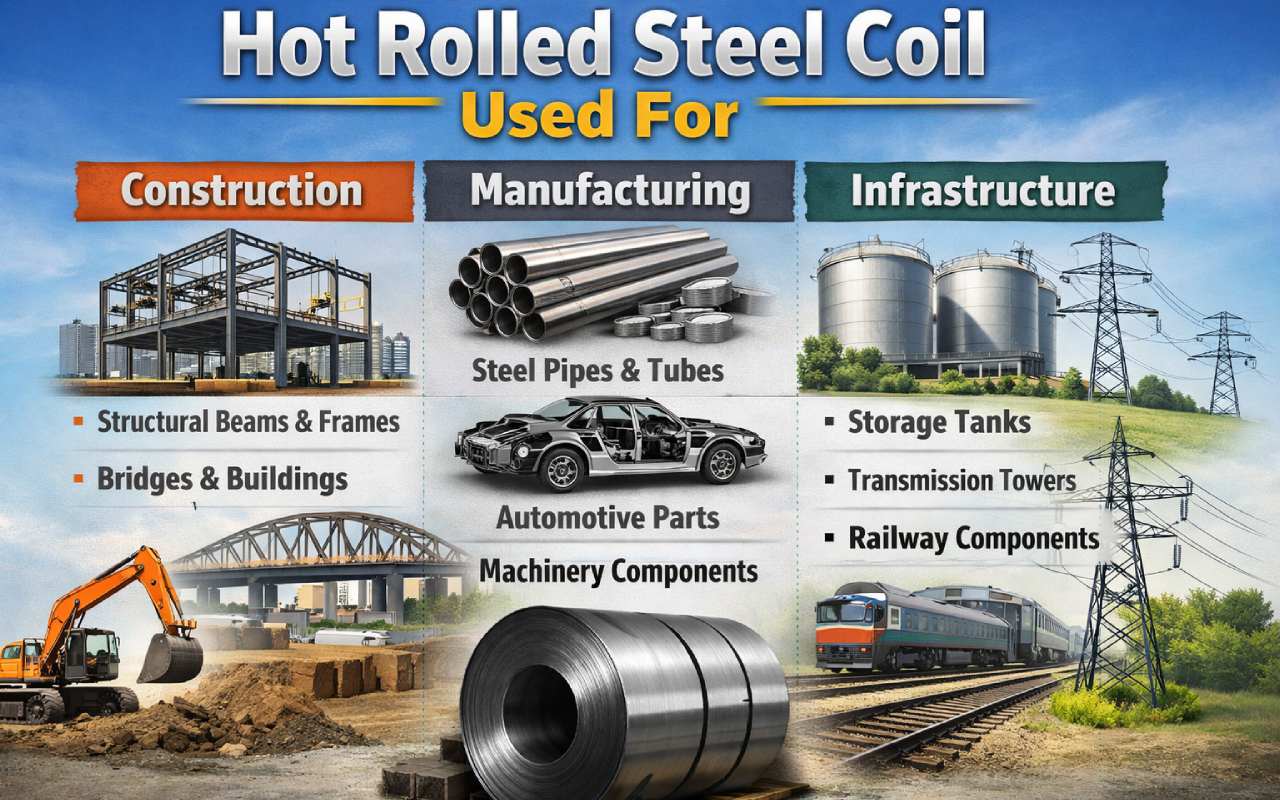

What Is Hot Rolled Steel Coil Used For?

Many buyers want to know what hot rolled steel coil is used for. Typical applications include:

Construction

Structural frames

Beams, angles, and channels

Industrial buildings and bridges

Manufacturing

Steel pipes and tubes

Machinery components

Automotive frames

Infrastructure

Storage tanks

Power transmission structures

Railway systems

It is also commonly used as a base material for further processing, such as pickled steel, galvanized steel, and cold rolled products.

Comparison with Cold Rolled Steel

Hot rolling and cold rolling differ mainly in processing temperature and final properties.

Hot rolled products focus on strength and cost efficiency.

Cold rolled products offer smoother surfaces and tighter tolerances.

The choice depends on application requirements rather than appearance alone.

Conclusion

Hot rolled steel coil remains an essential material for construction, manufacturing, and infrastructure projects. With its strong performance, easy processing, and reasonable cost, it continues to be a practical option for many steel buyers around the world.