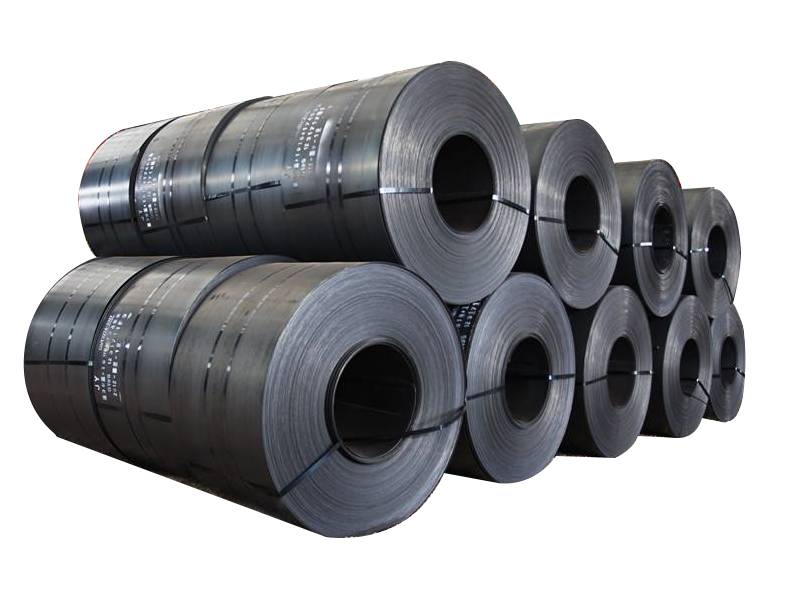

Hot Rolled Steel Coil

WhatsApp / Tel / Wechat

Still deciding? Get samples first, Contact US !

View similar products

- Product Description

-

Hot rolled steel coil (HRC) are steel that is rolled in a high-temperature environment and produced at the crystallization point, using this process can have excellent ductility, uniformity and ease of welding, and common uses include structural applications, auto parts, shipbuilding and large-scale projects. Steel plates are available in a variety of thicknesses and widths and can be further processed as required, such as cutting, bending, or shaping.

Hot Rolled Steel Coil Specifications

Thickness

0.8-16mm

Width

910-1600mm

Inner diameter

570mm

Roll weight

5-25t

Main Materials

The main materials used for hot-rolled coil steel are Q195, Q235B, Q345B, Q355B, Q355BH, Q355C, Q355D, Q345A, Q345E, SPHC, SPHE, SPHD, SAE1006

Hot Rolled Steel Coil Uses

Construction

Automotive

Shipbuilding & Marine

Machinery & Equipment

Metal Fabrication

Hot rolled steel coil Production process

Hot rolled steel coil production process: After the slab is heated to 1200°C, it is rolled into a rod in a rough tying machine by rough rolling to remove phosphorus, vertical roller edge grinding, and then flying shears are carried out to separate the head and tail. Then the phosphorus is removed through the finishing process, and the fine rolling is done to the required thickness, and the cooling and temperature control process is adopted to roll the bar into a coil through a coil making machine. In the final step, finishing processes such as flattening and shearing are required to produce finished products such as steel plates.

Slab out of furnace → Roughing dephosphorization box → Large vertical roller roughing mill → Hot coil box → Flying shear → Finishing dephosphorization device → Finishing vertical roller → Seven-stand finishing mill → Laminar cooling system → Downcoiler → Finishing line → Finished product

Thickness

Yield Strength

Tension strength

Elongation

>1.5-2.5

≤290Mpa

≥310Mpa

≥38

>2.5-3.0

≤290Mpa

≥300Mpa

≥38

>3.0-4.0

≤290Mpa

≥300Mpa

≥40

Features of Hot Rolled Steel Coil

Available in a variety of thicknesses and widths

High strength and excellent ductility

Uniform mechanical properties and surface finish

Easy to weld, cut, and form

Meets international standards (ASTM, EN, JIS)

Cost-effective solution for heavy-duty applications

Hot Rolled Steel Coil

WhatsApp / Tel / Wechat

Contact us via email

Still deciding? Get samples first, Contact US !

Products Category

Tag list

hot rolled carbon steel coil

Hot Rolled Carbon Steel Coil

Hot Rolled Coil

Hot Rolled Steel Coils

HRC

Hot Rolled Mild Steel Coil

Get a Free Quote

Note: Please leave your email address, our professionals will contact you as soon as possible!