C Channel Steel Sizes: Standard Dimensions and Specifications

C channel steel is a common steel product used in many industries. It is widely used in construction, factories, and infrastructure projects. Understanding c channel steel sizes helps buyers choose the right material. The correct size improves safety, reduces waste, and controls cost.

Shineyond Group is an experienced steel exporter. The company supplies C channel steel in many sizes and standards. Its products are used in building projects in many countries.

What Is C Channel Steel?

C channel steel has a cross section shaped like the letter “C”. It has one flat web and two flanges on the same side. This shape gives good strength and stability.

C channel steel is usually made from carbon steel. It can be produced by hot rolling or cold forming. Hot rolled C channel steel is thicker and stronger. It is often used in heavy structures. Cold formed C channel steel is lighter. It is often used in light steel frames.

Why C Channel Steel Sizes Are Important

Different projects need different c channel steel sizes. Size affects strength, weight, and cost. If the size is too small, the structure may not be safe. If the size is too large, the cost may be too high.

Choosing the correct size helps to:

Support the required load

Improve structural safety

Reduce material waste

Lower transport cost

Make installation easier

For these reasons, size selection is very important.

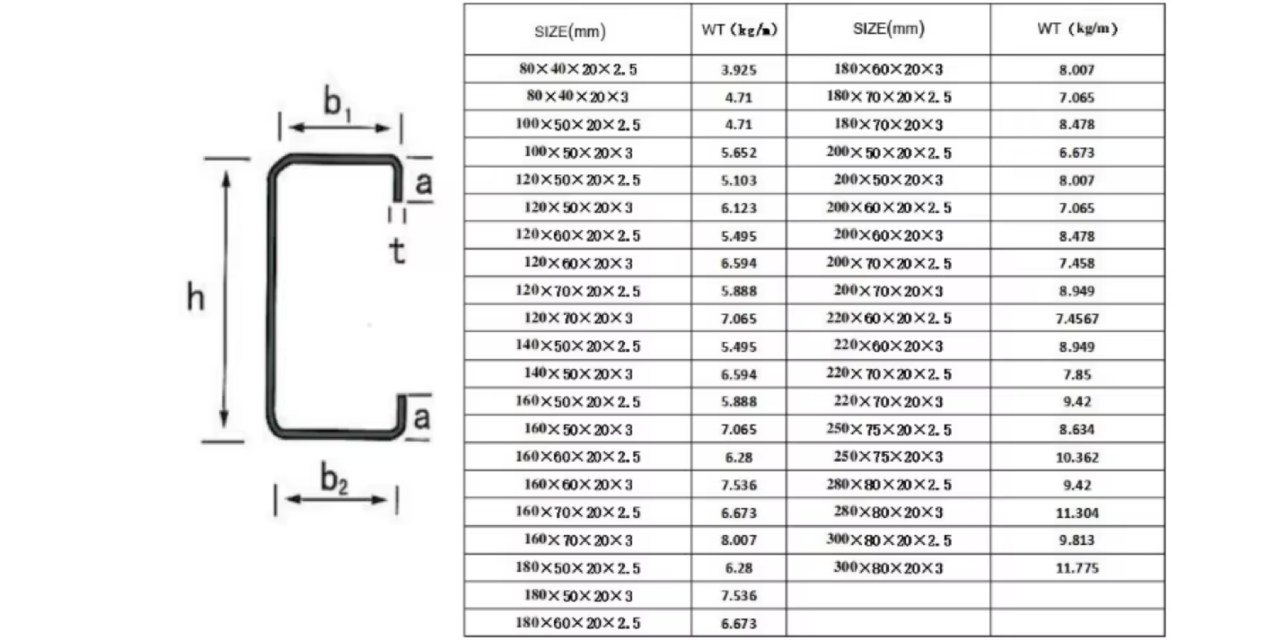

How C Channel Steel Sizes Are Measured

C channel steel sizes are defined by three main dimensions.

Web height (H). This is the vertical part.

Flange width (B). This is the horizontal part.

Thickness (T). This is the wall thickness.

Sizes are usually written as H × B × T. All dimensions are in millimeters.

Length is also important. Standard lengths are usually 6 meters or 12 meters. Shineyond Group can also supply custom lengths based on customer needs.

Common C Channel Steel Sizes

There are many standard c channel steel sizes used in the market. Some common sizes supplied by Shineyond Group include:

C80 × 40 × 5 mm

C100 × 50 × 5 mm

C120 × 50 × 5 mm

C140 × 60 × 6 mm

C160 × 65 × 6 mm

C180 × 70 × 7 mm

C200 × 75 × 8 mm

Smaller sizes are light and easy to install. Larger sizes provide higher strength and load capacity.

Standards for C Channel Steel Sizes

C channel steel sizes follow different standards in different regions. Shineyond Group supplies products that meet major international standards.

Common standards include:

ASTM A36 and ASTM A572

EN 10025 (S235, S275, S355)

JIS G3101

GB/T 706

Each standard defines chemical composition, strength, and size tolerance. Buyers should confirm the required standard before ordering.

Weight and Strength of C Channel Steel

The weight of C channel steel depends on its size and thickness. Larger sizes have more steel and more weight. They also have higher strength. Smaller sizes are lighter and easier to transport.

Weight is important for:

Structural design

Shipping and logistics

Installation planning

Shineyond Group provides clear weight tables for different c channel steel sizes. This helps buyers calculate total project weight and cost.

Applications Based on C Channel Steel Sizes

Different c channel steel sizes are used for different purposes.

Small sizes are often used for:

Light steel frames

Shelves and racks

Support brackets

Equipment bases

Medium sizes are commonly used for:

Building structures

Roof and wall supports

Steel platforms

Machinery frames

Large sizes are used for:

Factories and warehouses

Heavy steel structures

Industrial buildings

Infrastructure projects

Using the right size helps extend service life and improve performance.

How to Choose the Right C Channel Steel Size

Choosing the right size depends on several factors.

First, consider the load requirement. Heavier loads need larger sizes.

Second, consider the span length. Longer spans need stronger sections.

Third, consider the working environment. Outdoor use may need extra protection.

Fourth, consider local building codes and standards.

Finally, consider your budget.

Shineyond Group offers technical support. The team helps customers select suitable c channel steel sizes for their projects.

Why Choose Shineyond Group

Shineyond Group focuses on quality and reliability. The company has strong supply capacity and export experience.

Main advantages include:

Wide range of c channel steel sizes

Stable quality control

Competitive pricing

Flexible order quantities

Each order is inspected before shipment to ensure size accuracy and quality.

Conclusion

Understanding c channel steel sizes is essential for construction and industrial projects. Size affects strength, safety, and cost. With a full range of sizes, international standards, and professional service, Shineyond Group is a reliable supplier of C channel steel for global customers.