Effect of Chemical Composition on SAE 1008 Wire Rod Workability

SAE 1008 is a type of low-carbon steel that's a go-to for making wire rods because it bends easily and is simple to shape. What's in SAE 1008 really changes how well the wire rods work. The stuff it's made of impacts how strong it is, how smooth the surface looks, and how it changes when you bend it. If you want wire rods to do their job well in factories, knowing all this stuff is very important.

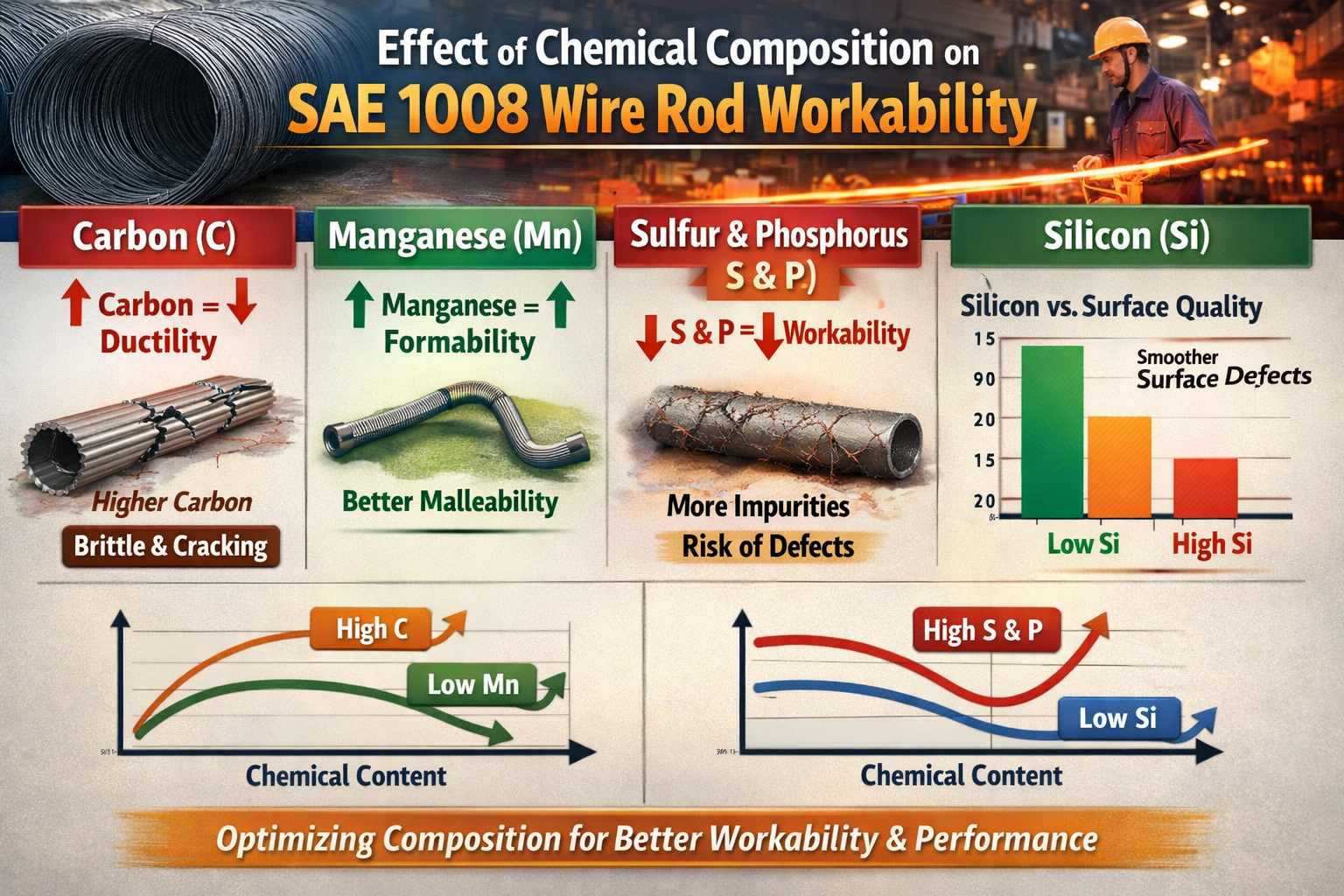

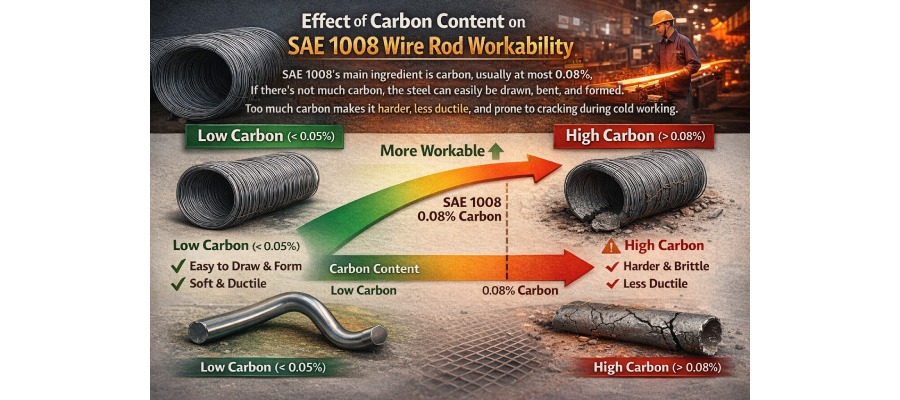

SAE 1008's main ingredient is carbon, usually at most 0.08%. How much carbon is in it really changes how hard and strong the wire is. If there's not much carbon, the steel can bend and be shaped easily, which is great for drawing, bending, and forming stuff. but If the amount of carbon is off by even a little, it can be harder to work with. Too much carbon makes it harder, less stretchy, and more likely to crack when you're shaping it cold.

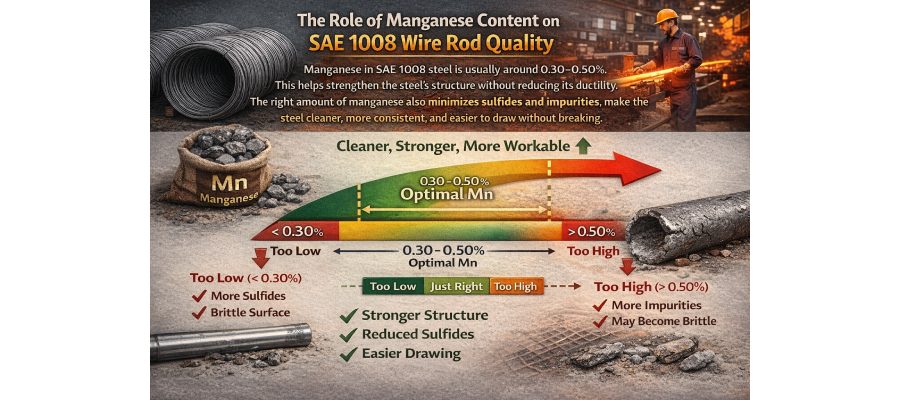

Manganese is also important. It's usually around 0.30–0.50%. It cleans up the steel and makes it stronger without losing bendiness. It also keeps sulfides from forming, which can mess up the surface or make it brittle inside if things aren't right. Just the right amount of manganese makes the steel consistent, so it's easier to work with and less likely to break when you're drawing it.

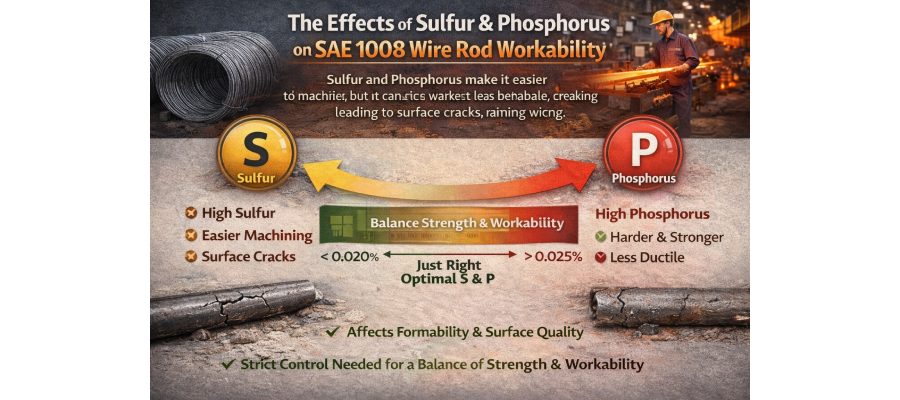

Sulfur and phosphorus, even in small amounts, really change how the wire works. A lot of sulfur can make it easier to machine, but it can also make it less bendable, leading to surface cracks. Phosphorus can make it stronger and harder, but it also makes it less stretchy and hard to form. So, keeping these elements in check is key to balancing strength and workability.

Other stuff like silicon and tiny bits of other metals also mess with how SAE 1008 behaves. Silicon makes it a bit stronger and harder and helps it not rust when it's hot rolled. Tiny amounts of copper or nickel might be added to help it resist rust or stay stable, but they're watched closely so they don't ruin workability.

Besides what's in it, how it's processed also matters. Things like rolling temperature, cooling speed, and lubrication all play with the steel's chemistry. low-carbon SAE 1008 wire needs careful rolling to avoid surface problems and keep its properties consistent. How it's made and what's in it together decide how workable it is, which is important for things like fasteners, springs, and regular wire stuff.

Basically, how easy SAE 1008 wire is to work with depends a lot on what it's made of. Keeping carbon low, manganese balanced, and sulfur and phosphorus controlled keeps it bendy, consistent, and easy to form. By understanding how each element changes things, makers can make better wire, have fewer problems, and make stuff that works better.