Wire Rods (Steel Wire Rod) | Raw Material Supplier

WhatsApp / Tel / Wechat

Still deciding? Get samples first, Contact US !

View similar products

- Product Description

-

What Are Wire Rods?

Wire rods, or carbon steel wire rods, are semi-finished steel products made by hot rolling billets into coils. Available in smooth and ribbed types, common diameters range from 5.5mm to 20mm, with custom sizes up to 12mm. Produced by Shineyond Group, our wire rods feature stable dimensions, excellent surface quality, high ductility, and reliable tensile strength for diverse industrial uses.

Steel Wire Rods Specifications

Coil Weight:

2mt, coil diameter 1.3m, length 1.6m

2.5mt , coil diameter 1.3m, length 1.8m

Commodity

Grade

Standard

Size

Application

Low carbon drawing wire

Q195 Q235

GB/T701-2008

5.5 - 20mm

Industrial wire drawing Wire mesh production

Low carbon

US StandardSAE1006/1008/1006B/1008B/

1018B/1045/1055/1022ASTM A510M

5.5 - 20mm

Industrial wire drawing ( export)

High carbon steel

45#、55#、60#、65#、70#

GB/T4354-2008

6.5 - 16mm

For industrial wire drawing, nail making, spring making, etc.

Prestressing Steel for Stranded Wires

SWRH62B、SWRH77B、SWRH82B

JIS G 3506

6.5mm 8-11mm

8-14mmFor steel nails, prestressing strands, scored wires, etc.

Electrode steel

H08A、H08MnA

GB/T3429-2015

6.5mm

Extracted wire is used as electrode core.

weld steel

ER70S-6

GB/T3429-2015

5.5 - 6.5mm

For the production of submerged arc welding wire

Cold heading steel

Japan standardSWRCH35K、SWRCH22A

JIS G 3507

6.5 - 16mm

5.5 - 6.5mmUsed for making standard parts, steel nails, self-tapping nails and drywall nails, etc.

Cold heading steel Enterprise standard

AS08

YB/T4155-2006

6.5 - 20mm

For making standard parts, nuts, bolts, etc.

Reinforced concrete

Hot-rolled ribbed steel bars

HRB400、HRB400E、HRB500、HRB500E

GB/T 1499.2-2018

8mm 12mm

Project construction

Reinforced concrete

Hot rolled round bars

HPB300

GB/T

1499.1-20176.5mm

Project construction

Steel rods for prestressed concrete

Hot Rolled Coil

30MnSi

GB/T 24587-2009

8-12mm

Project construction

Spring steel

65Mn

GB/T 1222-2016

6.5mm

For making springs

Alloy structural steel

20Mn2A

GB/T 1222-2016

6.5 - 14mm

For chain and chain making

Cord steel

C72DA、C82DA

GB/T 27691-2017

5.5mm

For the production of hose steel wire, tire bead steel wire

Wire rods Manufacturer

Wire rods are produced in various grades depending on the type of material used.

Carbon steel wire rod is the most widely used type and does not contain any minimum specified amounts of alloying elements such as molybdenum (Mo), aluminum (Al), chromium (Cr), niobium (Nb), cobalt (Co), nickel (Ni), tungsten (W), titanium (Ti), zirconium (Zr), or vanadium (V). It typically contains up to 0.40% copper, while the manganese content does not exceed 1.65%, and silicon levels are limited to a maximum of 0.60%.

wire rods are supplied in the following grades:

Low carbon:

The carbon content ≤ 0.15%. Generally we are also called "mild steel" or "electrode steel", and the size is 5.5-20mm.

Medium Carbon:

low grade; Carbon content 0.15% ≤ 0.23%

high grade; Carbon content 0.23% ≤ 0.44%.

High Carbon:

The carbon content > 0.44 %.

Shineyond Group is a professional global manufacturer of wire rods, using advanced production technology and strict quality control. Supply quality products that meet international standards.

Applications of Wire Rods

Wire rods are commonly used to manufacture:

Steel wire and binding wire

Nails and fasteners

Wire mesh and fencing

Springs and cables

Welding wire

Construction and industrial products

Wire Rod Grades Option

Wire rods can be supplied in different grades based on application needs:

Low carbon wire rod (drawing & binding)

Medium carbon wire rod (springs & fasteners)

High carbon wire rod (wires & cables)

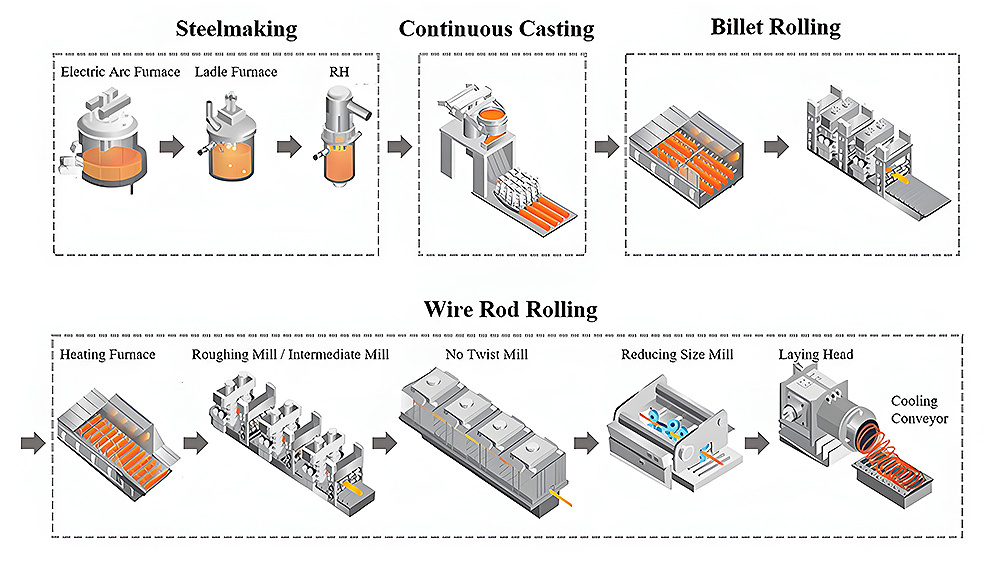

Steel Wire Rods Process

1. Heating Stage: Steel billets are heated to above 1100°C in a walking beam furnace to reach the ideal rolling temperature.

2. Descaling: High-pressure water jets are used to remove surface oxides from the heated billets.

3. Rough Rolling: The billets pass through the roughing mill, shaping them into an initial form.

4. Controlled Cooling: After rough rolling, the material is rapidly cooled in the water-cooling section to refine its metallurgical structure.

5. Finish Rolling: The semi-finished rod is rolled multiple times through intermediate and finishing mills to achieve the desired diameter and precision.

6. Coiling: The finished is discharged at high speed through the laying head, forming uniform, loose coils.

7. Air Cooling & Bundling: The coils are air-cooled to room temperature and collected into standardized bundles by the coiler.

8. Strapping: Each coil is compressed into a compact cylindrical form and securely strapped using automatic bundling machines.

9. Warehousing: The inspected and approved products are stored in the finished goods warehouse, ready for shipment.

Why Choose Shineyond Group's Wire Rods

As a reliable steel supplier, Shineyond Group provides wire rods trusted by global customers:

Stable quality and strict inspection

Bulk supply with competitive pricing

Export-standard packing and logistics

Technical support for wire processing

FAQ – Wire Rods

Q1: What are wire rods used for?

Wire rod coils are used to produce steel wires, nails, mesh, springs, and various wire products.

Q2: What is the difference between wire rod and rebar?

Wire rods are supplied in coils and used for drawing, while rebars are straight bars used for reinforcement.

Q3: Can wire rods be customized in grade or size?

Yes, wire rod diameter and steel grade can be customized according to application requirements.

Looking for a reliable Wire Rods supplier?

Please contact Shineyond Group for wire rods specifications, grades, and bulk prices.

Wire Rods (Steel Wire Rod) | Raw Material Supplier

WhatsApp / Tel / Wechat

Contact us via email

Still deciding? Get samples first, Contact US !

Products Category

Tag list

Wire rod

SAE1006 Wire rod

SAE1008 Wire rod

6.5mm Wire rod

5.5mm Wire rod

High carbon wire rod

Low carbon wire rod

Get a Free Quote

Note: Please leave your email address, our professionals will contact you as soon as possible!