Why is Rebar Used in Concrete? Importance Explained

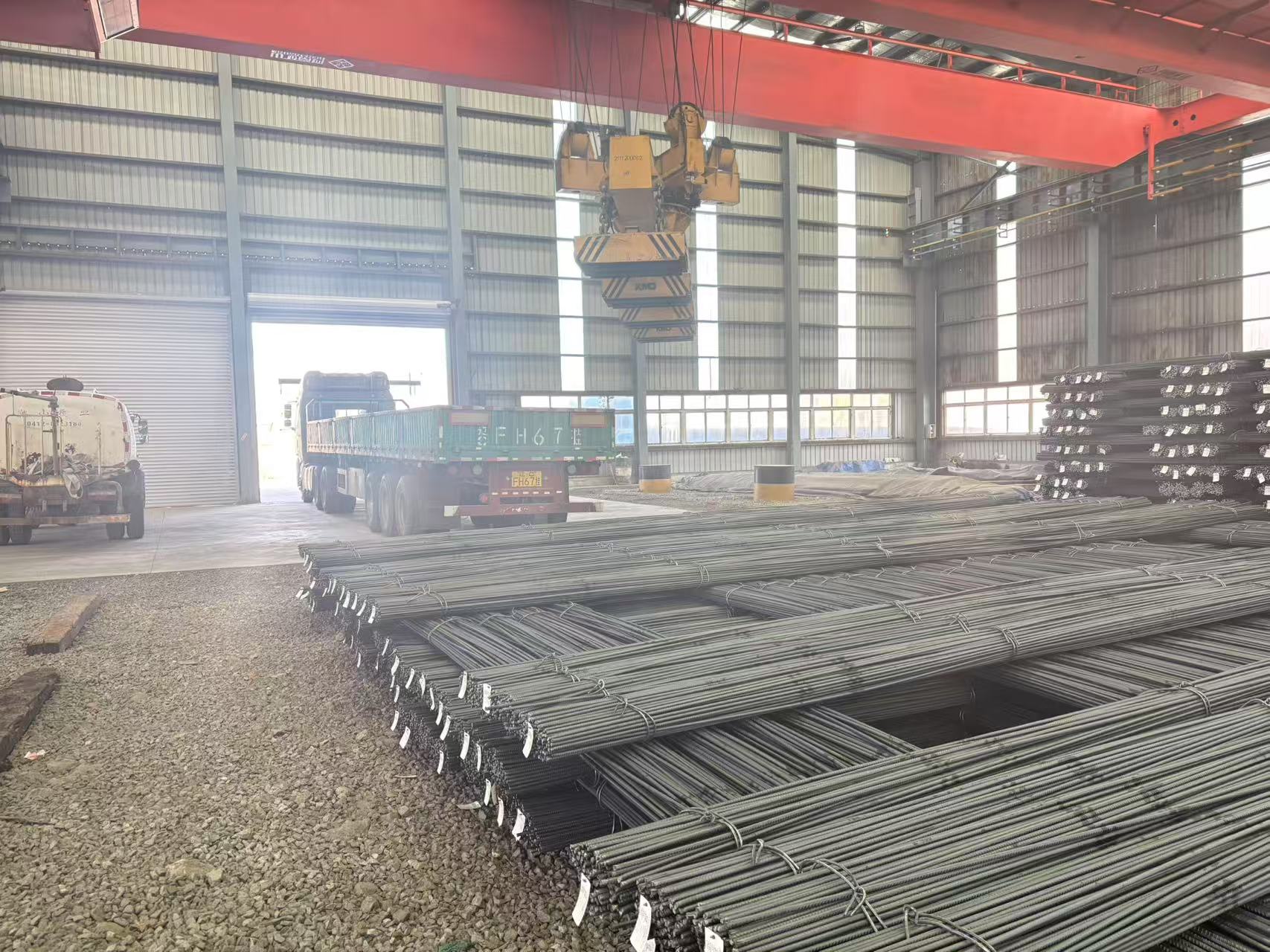

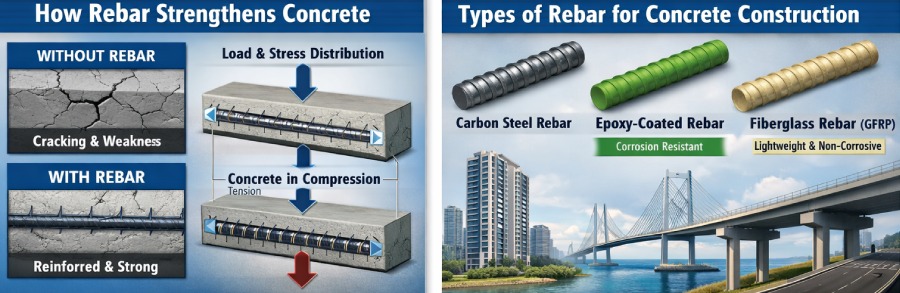

In the world of concrete construction, concrete is one of the most widely used materials due to its power and durability. However, on its own, concrete is strong in compression but weak in tension. This is where rebar (short for reinforcing bar), also known as steel rebar or reinforcing bar, comes in. Rebar is essential for enhancing the tensile strength of concrete, making structures safer and more durable.

The Engineering Synergy: How Rebar Strengthens Concrete

When concrete is poured into forms during concrete construction, it is subject to various forces such as bending, tension, and shear. Over time, these forces can cause cracks and structural failures. By embedding a steel bar into concrete, builders create a composite material that combines the compressive strength of concrete with the tensile strength of steel.

One fascinating reason this works so well is that steel and concrete have almost identical coefficients of thermal expansion. This means when temperatures change, they expand and contract at the same rate, preventing internal stress that would otherwise cause the structure to pull itself apart. Because concrete is strong only under weight, the addition of a steel bar is what prevents snapping under pressure.

Key Benefits of Using Rebar in Concrete

Improved Structural Integrity: Reinforced concrete resists bending and cracking, ensuring safety and stability even in seismic zones.

Longer Lifespan: Properly reinforced concrete can last decades, even under harsh environmental conditions, preserving the initial strength of concrete against wear and tear.

Cost-Effective: Although adding rebar (short for reinforcing bar) increases initial costs, it prevents costly repairs and structural failures in the future, offering a much higher return on investment (ROI).

Load Distribution: Rebar helps distribute heavy loads across a wider surface area, reducing the localized pressure on the concrete slab.

Versatile Applications: Rebar can be used in foundations, slabs, walls, columns, bridges, and highways.

Technical Selection: Choosing the Right Rebar

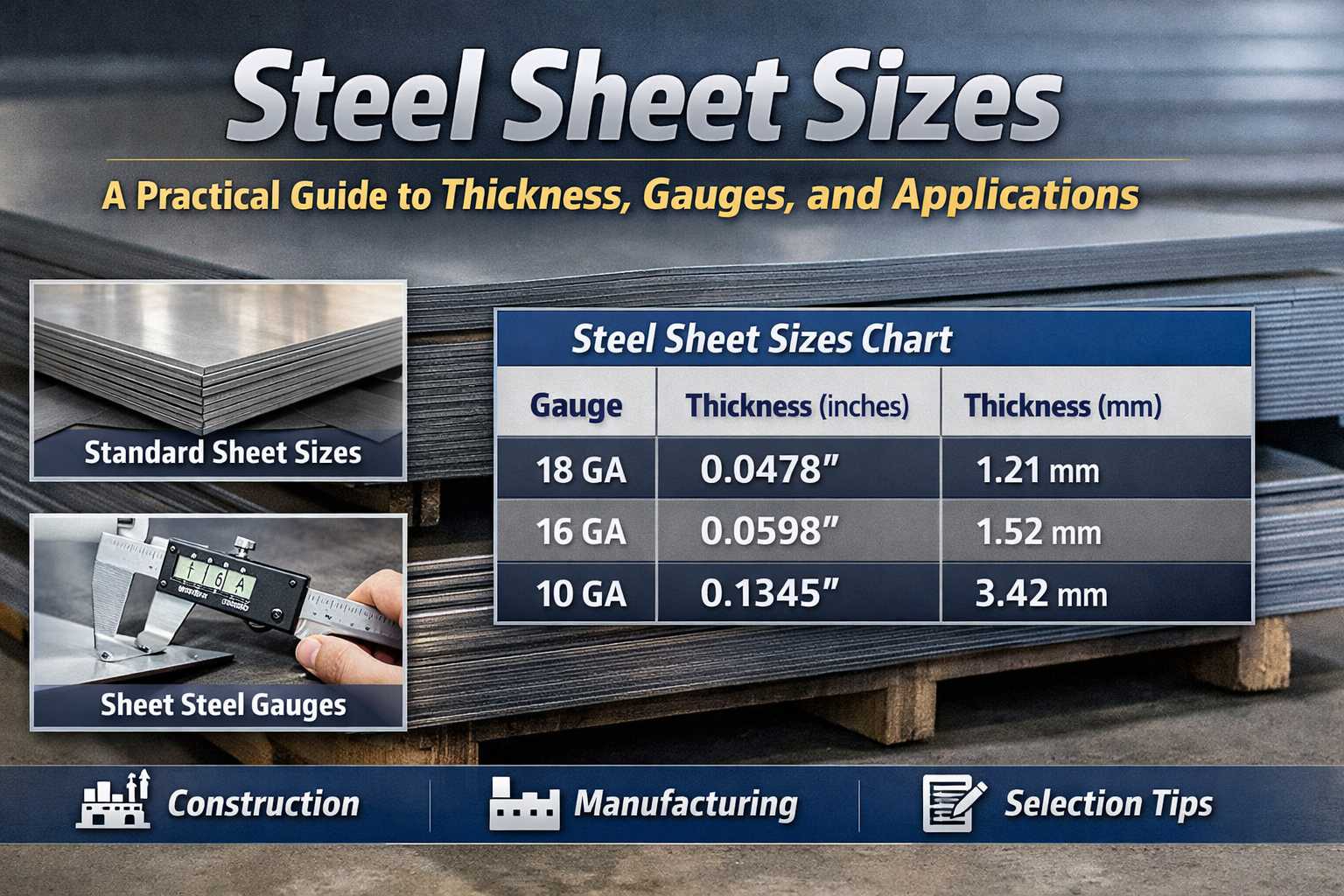

Selecting the appropriate reinforcing bar depends on the type of structure, environmental conditions, and load requirements. A critical factor in design is determining the correct rebar size. Rebar size is typically designated by numbers (e.g., #3, #4, #5), where each size corresponds to a specific diameter and cross-sectional area tailored to the weight it must support.

Common types include:

1. Carbon Steel Rebar: The industry standard for most concrete construction projects.

2. Epoxy-Coated Rebar: Used in bridges or coastal areas to fight corrosion from salt and moisture.

3. Fiberglass (GFRP) Rebar: A lightweight, non-conductive alternative that never rusts.

Selecting the right rebar size and material type ensures the project meets safety codes and engineering tolerances. Working with a reliable rebar supplier ensures the quality and compliance of materials with concrete construction standards.

Conclusion

The question, “why is rebar used in concrete?” is answered by its ability to enhance tensile strength and durability. From residential buildings to large infrastructure projects, steel rebar plays a crucial role in creating safe and long-lasting concrete structures. For any concrete construction project, sourcing quality steel bar materials and the correct rebar size from trusted rebar suppliers is essential for success.

By reinforcing the natural strength of concrete with the flexibility of steel, we can build taller, longer, and safer structures that stand the test of time.