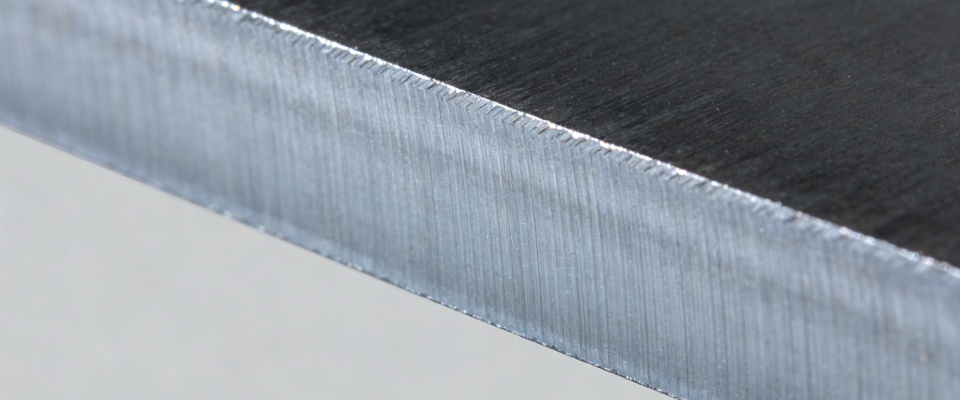

How to choose the right edge type for a cold rolled steel strip?

Choosing the right edge type for a cold rolled steel strip is a critical decision that balances functionality, safety, and production costs. The "edge" refers to the finish of the strip's longitudinal sides, and it significantly impacts how the material behaves during stamping, welding, or final use.

Here is a guide to selecting the appropriate edge for your project.

Understanding Common Edge Types

The industry typically classifies edges based on how much secondary processing they receive after the initial slitting or rolling.

No. 1 Edge (Prepared Edge)

This is a premium edge that has been rolled or filed to a specific shape, usually a perfect round or a square. It is completely free of burrs and provides the highest level of dimensional accuracy.

No. 2 Edge (Mill Edge)

This is the natural edge produced during the hot rolling process and maintained through cold rolling. It is unrefined and irregular. While it is the most economical, it has wide width tolerances and may contain small cracks or "fish-scale" imperfections.

No. 3 Edge (Slit Edge)

This is the most common industrial edge. It is produced by passing the steel through rotary slitters. While it offers precise width control, it inherently possesses a "burr"—a sharp, raised lip on one side of the cut.

No. 4 & No. 6 Edges (Rounded and Square)

These are produced by edge rolling. A No. 4 edge is rounded and smooth, ideal for applications where the edge is exposed. A No. 6 edge is a square-rolled edge used when a neat, rectangular profile is required without the sharpness of a slit edge.

No. 5 Edge (Deburred Edge)

This starts as a No. 3 slit edge but passes through a secondary process (like rolling or grinding) to flatten or remove the burr. It is safer to handle than a slit edge but less precise than a No. 1 edge.

If you need a steel strip, you can click here to view the product details.

Key Factors for Selection

To choose the right edge, evaluate your requirements against these four criteria:

Safety and Exposure

If the edge of the steel will be touched by consumers (such as in handrails, shelving, or tools), you must specify a No. 1, No. 4, or No. 5 edge. A standard No. 3 slit edge is sharp enough to cause injuries and can snag clothing or cleaning materials.

Tooling and Die Life

Slit edges (No. 3) have a work-hardened burr. In high-speed stamping operations, this burr acts like a tiny abrasive tool, accelerating the wear on your expensive dies. If you are running millions of parts, switching to a No. 5 (Deburred) edge can significantly extend the interval between tool sharpenings.

Formability and Stress

During severe bending or drawing, the micro-cracks or burrs on a No. 3 edge can act as "stress risers," causing the steel to split or crack along the side. For safety-critical components or parts with tight radiuses, a No. 1 or No. 4 rounded edge is much more resilient under mechanical stress.

Welding and Assembly

For automated butt-welding, a No. 1 or No. 6 square edge provides the best fit-up, ensuring a consistent weld bead. If the edges are slightly uneven (as with No. 2), you may face gaps that lead to weak joints or burn-through.

Summary of Recommendations

For Maximum Economy: Use No. 3 (Slit) if the edge is hidden inside an assembly and the forming is not severe.

For Human Contact: Use No. 1 or No. 5 to ensure safety and a smooth feel.

For Complex Bending: Use No. 1 or No. 4 to prevent edge cracking during the manufacturing process.

For Critical Dimensions: Use No. 1 to maintain the tightest width and shape tolerances.