What Is Painted Steel Coil? A Comprehensive Buyer’s Guide

Introduction

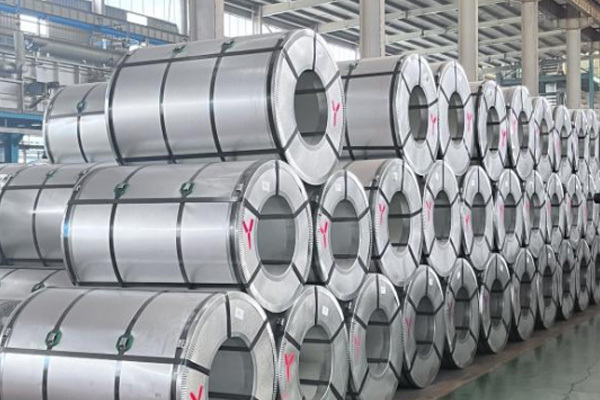

What Is a Painted Steel Coil?

A painted steel coil, also known as pre-painted steel or color coated steel, is a flat steel product that has been coated with organic paint layers in a controlled factory environment before fabrication.

Instead of painting steel after forming, painted steel coils are finished in advance, ensuring consistent quality, strong adhesion, and long-term performance.

From Raw Steel to Finished Material

The core concept of painted steel coil lies in transforming raw steel—such as cold-rolled, galvanized, or galvalume steel—into a functional, corrosion-resistant, and aesthetically pleasing material ready for immediate use.

Market Importance

Painted steel coils are widely preferred in modern construction and manufacturing because they:

Reduce processing time

Improve durability

Offer design flexibility

Lower total project costs

As a result, they are a key material in global building, appliance, and infrastructure projects.

The Anatomy of a Painted Steel Coil

A painted steel coil is not just “steel with paint.” It is a multi-layer engineered system, where each layer serves a specific function.

Base Metal Options

Cold Rolled Steel (CR): Smooth surface, used mainly for indoor applications

Galvanized Steel (GI): Zinc-coated for corrosion protection

Galvalume Steel (GL): Aluminum-zinc alloy coating for enhanced durability

Coating Layer Structure

1. Top Coating (Finish Coat)

Provides color, UV resistance, and weather protection

2. Primer Coat

Ensures strong adhesion between paint and steel

3. Pre-treatment Layer

Chemical conversion coating that improves corrosion resistance

4. Back Coating

Protects the reverse side during handling and service life

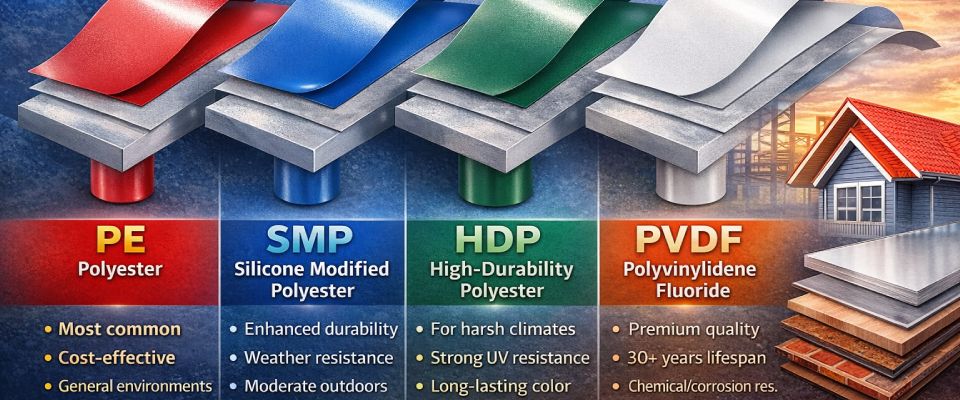

Types of Coating Materials (The Science)

Choosing the right paint system is critical for performance and lifespan.

PE (Polyester)

Most widely used

Cost-effective

Suitable for general environments

SMP (Silicone Modified Polyester)

Better weather resistance than PE

Improved color retention

Suitable for moderate outdoor exposure

HDP (High-Durability Polyester)

Designed for harsh climates

Strong UV resistance

Long-lasting color stability

PVDF (Polyvinylidene Fluoride)

Premium coating system

Excellent chemical and corrosion resistance

Lifespan of 30+ years

Ideal for coastal and industrial environments

The Manufacturing Process

Painted steel coils are produced through a continuous coil coating line, ensuring uniform quality.

Step 1: Cleaning & Pre-treatment

Steel is cleaned to remove oil, dust, and impurities, then chemically treated to enhance coating adhesion.

Step 2: Coil Coating

Paint is applied using a roll coating method, allowing precise control of coating thickness.

Step 3: Baking & Curing

The coated steel passes through high-temperature ovens to cure and harden the paint layers.

Step 4: Quality Control

Strict tests are conducted, including:

T-bend test

Pencil hardness test

Salt spray test

Key Benefits for Buyers

Corrosion Resistance

The coating system forms a strong barrier that prevents moisture and oxygen from reaching the steel surface.

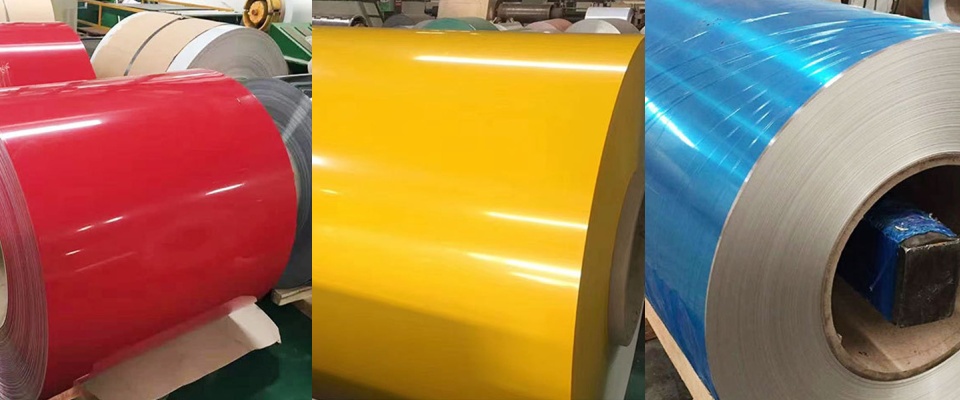

Aesthetic Versatility

Painted steel coils are available in:

RAL color systems

Matte, glossy, or textured finishes

Wood grain or brick-pattern effects

Cost Efficiency

Pre-painted coils eliminate the need for on-site painting, reducing labor, time, and maintenance costs.

Sustainability

Steel is fully recyclable, and long service life reduces material waste over time.

Main Applications

Construction

Roofing sheets

Wall cladding

Garage doors

Home Appliances

Refrigerator panels

Washing machine shells

Microwave exteriors

Transportation

Shipping containers

Vehicle body components

Buyer’s Checklist: How to Choose the Right Coil

1. Environmental Conditions

Is the project located near the ocean, in a humid climate, or an industrial zone?

2.Coating Thickness

Understand coating systems such as:

15/5 μm (top/back) for standard use

25/10 μm for enhanced durability

3. Color Stability

Look for coatings with strong chalking and fading resistance, especially for outdoor projects.

4. Budget vs Performance

PE for cost-sensitive projects

PVDF for long-term, high-exposure environments

Conclusion

Painted steel coil is a smart investment for buyers seeking durability, efficiency, and design flexibility. With the right base metal and coating system, it delivers long-term value across construction and manufacturing applications.

Contact us today for a customized quote, technical consultation, or product samples tailored to your project needs.