Deformed Bar vs Rebar: Understanding the Differences and Applications

When it comes to reinforced concrete construction, deformed bars and rebar are terms often used interchangeably. However, subtle differences exist between them, and understanding these distinctions can help engineers, contractors, and builders make informed decisions. This article explores the comparison between deformed bar vs rebar, rebar vs deformed bar, and the broader context of deformed bars vs rebar in construction.

What is Rebar?

Rebar, short for reinforcing bar, is a steel bar used to strengthen and hold concrete under tension. Concrete is strong in compression but weak in tension, which is where rebar comes into play. It provides the tensile strength needed to prevent cracking and structural failure. Rebar is typically available in different grades, diameters, and lengths to suit various structural applications. The most common type is plain rebar, which has a smooth surface.

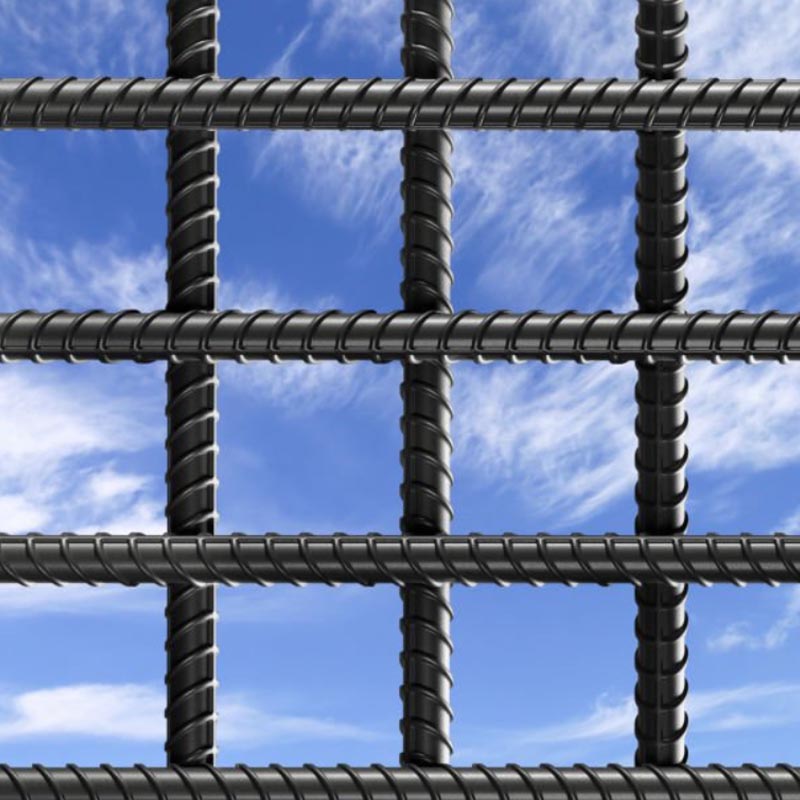

What are Deformed Bars?

Deformed bars are a type of rebar that has ridges, lugs, or indentations along their length. These surface deformations improve the bond between the steel and concrete, ensuring better load transfer and reducing the chances of slippage. Deformed bars are particularly essential in high-stress areas of construction, such as beams, columns, and slabs, where enhanced grip is required.

Deformed Bar vs Rebar: Key Differences

While all deformed bars are technically rebar, not all rebar is deformed. Here’s a quick comparison:

1. Surface Texture:

Rebar can be plain or deformed.

Deformed bars always have ridges or patterns to improve bonding with concrete.

2. Bond Strength:

Plain rebar relies mostly on friction for bonding.

Deformed bars offer superior mechanical interlock with concrete, making them ideal for critical structural applications.

3. Applications:

Plain rebar is suitable for low-stress or secondary structures.

Deformed bars are preferred for primary load-bearing elements like columns, beams, and reinforced slabs.

4. Cost:

Deformed bars are slightly more expensive due to additional manufacturing processes but provide better performance in terms of safety and longevity.

Rebar vs Deformed Bar in Construction

In practical construction, choosing between rebar vs deformed bar often depends on the structural requirements:

For Residential Projects: Plain rebar may be used in non-critical areas, such as sidewalks or minor slabs.

For Commercial or High-Rise Buildings: Deformed bars are essential for all major structural components to ensure safety under high loads.

Earthquake-Prone Areas: Deformed bars provide improved ductility and bond strength, making them the preferred choice.

Deformed Bars vs Rebar: Making the Right Choice

Understanding the difference between deformed bars vs rebar is crucial for material selection and cost optimization. While plain rebar may suffice for minor projects, deformed bars offer better performance in terms of strength, durability, and safety. Contractors often choose deformed bars for long-term structural reliability, especially in concrete structures exposed to heavy loads or harsh environmental conditions.

Conclusion

The debate of deformed bar vs rebar, rebar vs deformed bar, or deformed bars vs rebar ultimately comes down to the specific requirements of a construction project. Deformed bars provide enhanced bonding, improved load-bearing capacity, and greater durability, making them the preferred choice for most modern reinforced concrete structures. By selecting the right type of rebar, builders can ensure both safety and longevity for their projects.