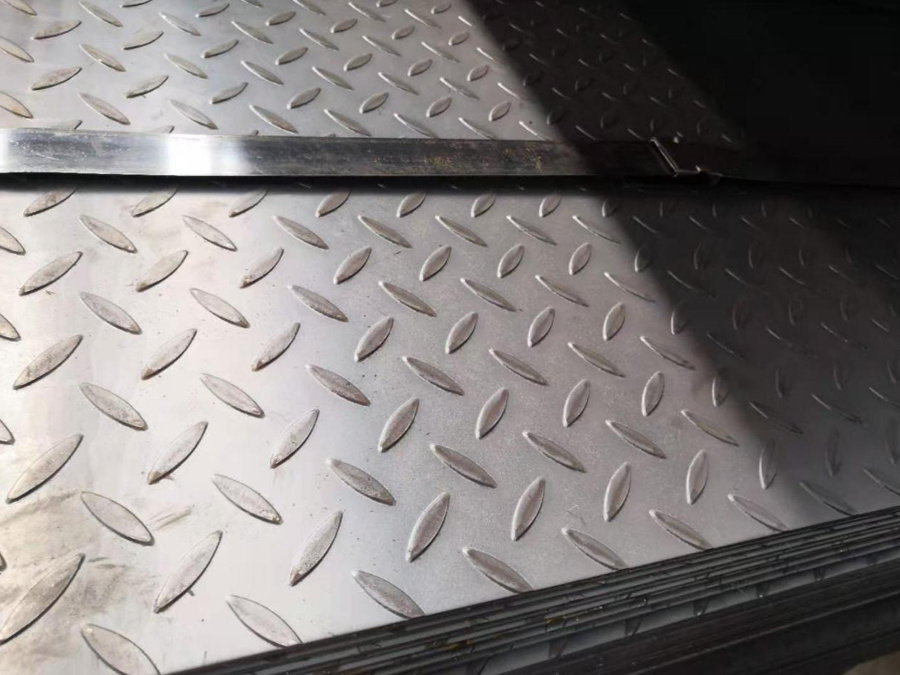

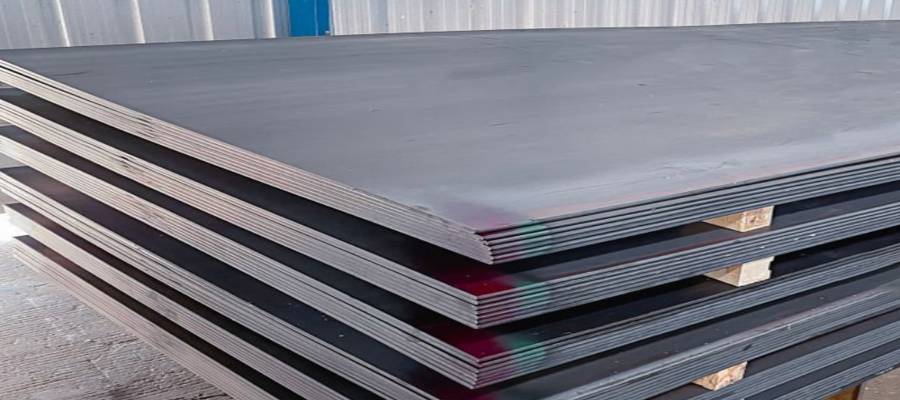

Low Carbon Steel Plate: Grades, ASTM Standards, and Industrial Applications

Low carbon steel plate is a highly versatile material used across construction, automotive, manufacturing, and industrial sectors. It is prized for its excellent weldability, good formability, and moderate strength. This type of steel works well in structural applications and other projects that do not require high alloy content. Its affordability, adaptability, and consistent quality make it a popular choice for engineers, project managers, and buyers worldwide.

Understanding Low Carbon Steel Plate Grades

Choosing the right steel starts with understanding low carbon steel plate grades. Grades affect mechanical properties, chemical composition, and suitability for different uses. Common grades include A36 steel, ASTM A1011, and AISI 1018.

A36 Steel: This structural plate meets the low carbon steel plate ASTM standard. It provides excellent minimum yield strength, making it ideal for bridges, buildings, and heavy machinery frameworks.

ASTM A1011: This hot-rolled plate is commonly used in automotive panels, construction components, and general manufacturing. It has a smooth surface and works well with heat treatment, allowing easy fabrication and welding.

AISI 1018: Known for uniform microstructure, this grade is suitable for precision machining, bending, and moderate-strength applications.

In addition, high strength low alloy (HSLA) steel plates offer enhanced tensile strength and wear resistance while maintaining good formability. These plates are suitable for projects that demand higher load-bearing capacity or high temperature performance.

Compliance with ASTM Standards

Meeting low carbon steel plate ASTM standards is critical for quality and consistency. ASTM specifications define chemical composition, mechanical properties, dimensional tolerances, and surface quality. Using ASTM-certified steel ensures that the plates can safely support pressure vessels, structural frameworks, and heavy machinery.

Other standards such as ISO, JIS, and EN may also apply depending on regional requirements. However, ASTM remains the most recognized and trusted standard, especially in international trade. Following these standards ensures consistent quality, safety, and reliable performance.

Mechanical Properties and Heat Treatment

Low carbon steel plates have excellent mechanical properties, making them highly adaptable. Proper heat treatment, including quenched and tempered processes, increases hardness, toughness, and corrosion resistance. Plates treated this way achieve superior tensile strength and minimum yield strength, which is essential for demanding industrial applications.

With the right combination of carbon content, structural steel characteristics, and optional high strength low alloy variants, manufacturers can meet diverse project requirements. When needed, these plates also maintain performance under high temperature conditions. This makes them suitable for specialized uses such as boilers, industrial ovens, and high-pressure equipment.

Wide-Ranging Applications

Low carbon steel plates are used in multiple industries due to their strength, flexibility, and reliability. Common applications include:

1. Construction: Plates are used in beams, columns, and frameworks where structural steel is critical. They provide stability and long-term durability for bridges, buildings, and other large-scale projects.

2. Pressure Vessels: Tanks, storage containers, and other high-pressure equipment rely on ASTM-certified low carbon steel. Its minimum yield strength and tensile strength make it safe and dependable.

3. Automotive Industry: Low carbon steel plates are used for car bodies, chassis, and panels. Their weldability and flexibility ensure parts are durable yet easy to manufacture.

4. Manufacturing: Machinery housings, industrial components, and equipment often use low carbon steel plates. Proper heat treatment allows the steel to perform reliably while being easy to shape, cut, or weld.

5. Shipbuilding and Heavy Equipment: Hulls, cranes, and structural components benefit from low carbon steel’s toughness and corrosion resistance. Quenched and tempered plates offer extra durability under harsh conditions and heavy loads.

The versatility of these plates allows them to be fabricated into custom shapes and sizes, making them ideal for a wide range of structural applications.

Advantages of Low Carbon Steel Plate

Low carbon steel plates are widely preferred due to several key benefits:

Excellent Weldability: Plates join easily without losing mechanical strength.

Good Formability: Low carbon content allows bending, cutting, and shaping without cracking.

Durability: Proper heat treatment and surface finishing improve wear and corrosion resistance.

High Mechanical Performance: HSLA grades provide improved tensile strength and minimum yield strength.

Cost-Effectiveness: Compared to high-carbon or alloyed steels, low carbon steel plates are affordable while still performing well.

Sourcing Low Carbon Steel Plate from China

China is a major supplier of low carbon steel plate, offering competitive pricing and compliance with low carbon steel plate ASTM standards. When sourcing plates, buyers should consider:

Grade and standard compliance, ensuring ASTM or ISO certification.

Mechanical properties, including tensile strength, minimum yield strength, and corrosion resistance.

Dimensions and thickness to match project specifications.

Supplier reliability and certifications to ensure quality and consistency.

Reputable suppliers provide plates suitable for both domestic and international projects, including construction, automotive, and heavy machinery applications.

Conclusion

In summary, low carbon steel plate is a cornerstone of modern industry. Its combination of weldability, corrosion resistance, tensile strength, and adaptability makes it suitable for structural applications, pressure vessels, automotive parts, and machinery components.

By understanding low carbon steel plate grades and choosing ASTM-certified materials, engineers, project managers, and buyers can achieve optimal performance, safety, and durability. With proper heat treatment and fabrication, these plates provide long-lasting and reliable solutions across a wide range of industrial applications worldwide.