Carbon Steel Rebar in Modern Construction

Carbon steel rebar is a core material used in reinforced concrete structures. Concrete is strong when pressed, but weak when pulled. Steel reinforcement helps solve this problem. By working together, concrete and steel create strong and stable structures used all over the world.

What Is Carbon Steel Rebar?

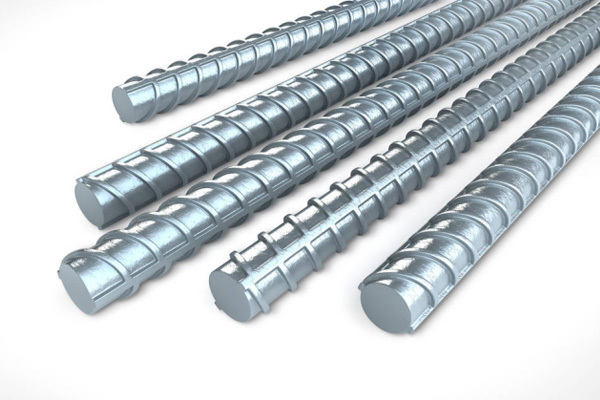

Carbon steel rebar is a reinforcing bar made mainly from iron and carbon. The carbon content helps improve strength and hardness. Most products used in construction have a deformed surface with ribs. These ribs increase friction between steel and concrete. This helps both materials stay bonded under load.

These reinforcing bars are usually produced by hot rolling. They are supplied in many sizes and grades. This makes them suitable for small buildings and large infrastructure projects.

Key Properties of Carbon Steel Rebar

One important feature of carbon steel rebar is high tensile strength. It can carry tension forces that concrete alone cannot handle. This helps reduce cracking and structural damage.

Another key property is ductility. The steel can bend under stress instead of breaking suddenly. This is very important for safety, especially in seismic areas. The material is also easy to process. It can be cut, bent, and welded on site. In addition, it offers good value for money compared with other reinforcement materials.

Grades and Standards for Carbon Steel Rebar

Carbon steel rebar is produced according to international standards. Common standards include ASTM, BS, DIN, and GB. These standards control strength, size, and chemical composition.

Under ASTM A615, Grade 40 and Grade 60 are widely used. Grade 60 provides higher yield strength and is often used in heavy-load structures. Engineers choose the grade based on design needs, building codes, and project conditions.

Manufacturing Process of Carbon Steel Rebar

The production process starts with melting raw materials in a furnace. The molten steel is then cast into billets. These billets are reheated and rolled into round bars.

During rolling, surface ribs are formed to improve bonding with concrete. After cooling, the bars are cut to standard lengths. Quality checks are carried out to confirm size accuracy and mechanical performance.

Applications of Carbon Steel Rebar

Carbon steel rebar is used in almost all types of concrete structures. It is common in residential housing, commercial buildings, and office towers. Infrastructure projects such as bridges, highways, and tunnels also rely on this material.

Foundations, beams, columns, and floor slabs all require strong reinforcement. Large projects like dams, ports, and industrial plants also depend on reliable steel reinforcement to ensure long service life.

Advantages and Limitations of Carbon Steel Rebar

One major advantage is availability. Carbon steel rebar is easy to source in global markets. It offers a good balance between strength, performance, and cost. This makes it a practical choice for most construction projects.

However, in wet or coastal environments, corrosion can occur over time. To reduce this risk, builders often use proper concrete cover or protective treatments. These methods help extend durability.

Conclusion on Carbon Steel Rebar

Carbon steel rebar remains one of the most important materials in the construction industry. It improves structural strength and supports long-term safety. With simple processing, wide application, and reasonable cost, it continues to be a trusted reinforcement solution for concrete structures worldwide.