Cold Rolled Carbon Steel Plate: Complete Guide

Cold rolled carbon steel plate, also known as cold rolled steel plate, is a high-precision flat steel product widely used in construction, manufacturing, automotive, home appliances, and industrial equipment. Thanks to its smooth surface, tight thickness tolerance, and excellent mechanical properties, it has become an essential material in modern industry.

This guide will help you fully understand what cold rolled carbon steel plate is, how it is made, its specifications, grades, applications, advantages, and how to choose the right product for your projects.

What Is Cold Rolled Carbon Steel Plate?

Cold rolled carbon steel plate is produced by further processing hot rolled carbon steel at room temperature. After pickling to remove surface scale, the steel is rolled through cold reduction mills to achieve:

More accurate thickness

Higher strength

Better surface quality

Tighter dimensional tolerance

Because of this process, cold rolled steel plate offers superior performance compared with hot rolled steel in applications where appearance, precision, and strength consistency are critical.

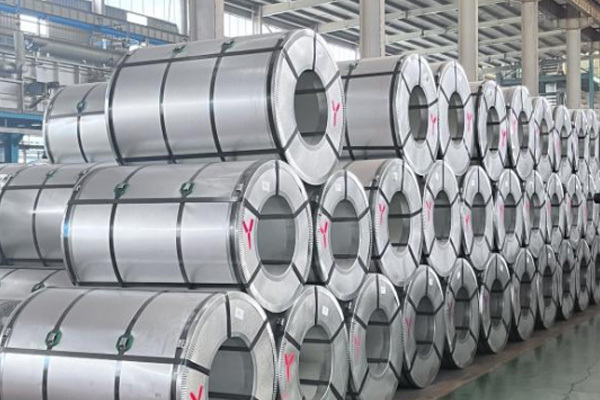

It is typically supplied in sheets or coils, and widely used in structural parts, forming applications, and decorative products.

Cold Rolling Process Explained

The production of cold rolled steel plate generally includes the following steps:

1.Hot Rolled Steel as Raw Material

2.The process starts with hot rolled carbon steel coils.

3.Pickling

4.The steel passes through acid solutions to remove oxide scale and rust.

5.Cold Rolling (Cold Reduction)

6.The steel is rolled at room temperature through several rolling stands, reducing thickness and improving surface finish.

7.Annealing

8.The steel is heat-treated to restore ductility that was lost during cold rolling.

9.Skin Pass / Temper Rolling

10.A light finishing roll improves flatness and surface appearance.

This process results in cold rolled steel with higher strength, smooth surface, and improved formability.

Key Properties of Cold Rolled Carbon Steel Plate

Cold rolled steel plate offers a well-balanced combination of mechanical and surface properties.

✅ Mechanical Properties

Higher tensile strength than hot rolled steel

Excellent yield strength consistency

Good elongation after annealing

✅ Surface Quality

Smooth and clean surface

Suitable for painting, coating, and plating

No visible oxide scale

✅ Dimensional Accuracy

Tight thickness tolerance

Superior flatness

Precise width control

These properties make cold rolled carbon steel plate ideal for precision forming, bending, stamping, and welding.

Common Grades and Standards

Cold rolled carbon steel plate is produced according to various international standards:

✅ ASTM (USA)

SPCC – General commercial quality

SPCD – Drawing quality

SPCE – Deep drawing quality

ASTM A1008 CS/DS/SS – Commercial, drawing, and structural grades

✅ EN (Europe)

DC01, DC03, DC04, DC05, DC06

✅ JIS (Japan)

SPCC, SPCD, SPCE

✅ Chinese Standard

Q195, Q235, Q345 (cold rolled versions)

Each grade serves different forming requirements, from basic structural use to deep drawing applications.

Standard Sizes and Thickness Range

Typical specifications of cold rolled carbon steel plate include:

Thickness: 0.2 mm – 3.0 mm

Width: 600 mm – 1,500 mm

Length: 1,000 mm – 6,000 mm (custom available)

Supply Form: Sheet or Coil

Customization of width, length, and tolerance is commonly available from professional manufacturers.

Main Applications of Cold Rolled Steel Plate

Cold rolled steel plate is widely used across many industries due to its excellent formability and appearance.

✅ Automotive Industry

Car body panels

Structural reinforcements

Interior components

✅ Home Appliances

Refrigerators

Washing machines

Air conditioners

Microwave ovens

✅ Construction & Decoration

Light steel structures

Ceiling panels

Door and window frames

Decorative metal panels

✅ Furniture & Office Equipment

Filing cabinets

Office desks

Steel shelves

✅ Electrical & Industrial Equipment

Electrical enclosures

Control cabinets

Precision machine parts

Cold Rolled vs Hot Rolled Steel Plate

ItemCold Rolled Steel PlateHot Rolled Steel PlateSurfaceSmooth & cleanRough with oxide scaleAccuracyHighLowerStrengthHigherLowerThicknessThin (0.2–3.0 mm)Thick (≥1.5 mm)CostHigherLowerApplicationsPrecision partsStructural parts

In general, cold rolled steel is used when precision and appearance matter, while hot rolled steel is used for heavy structures and load-bearing applications.

Advantages of Cold Rolled Carbon Steel Plate

✅ Excellent surface finish for coating and painting

✅ High strength-to-weight ratio

✅ Tight dimensional tolerance

✅ Superior formability after annealing

✅ Wide range of grades and sizes

✅ Suitable for mass industrial production

These advantages make cold rolled steel plate a core material in modern manufacturing.

How to Choose the Right Cold Rolled Steel Plate

When selecting cold rolled carbon steel plate, consider the following factors:

1.Application Requirement

2.Structural parts, deep drawing, stamping, or decorative use?

3.Grade Selection

4.Choose SPCC for general use, SPCD/SPCE for deep drawing.

5.Thickness & Tolerance

6.Precision projects require tight thickness control.

7.Surface Finish

8.Bright finish is recommended for coating or painting.

9.Quantity & Supply Form

10.Coil for mass production, sheet for fabrication.

11.Standards Compliance

12.Make sure the product meets ASTM, EN, JIS, or local standards.

Storage and Handling Tips

To maintain quality during storage and transport:

Store in dry, ventilated environments

Avoid contact with moisture and acids

Use anti-rust oil or protective packaging

Keep off direct ground contact

Proper storage prevents surface oxidation and quality deterioration.

Market Outlook and Industry Demand

With the global growth of:

Automotive manufacturing

Household appliance production

Light steel construction

Urban infrastructure

The demand for cold rolled carbon steel plate continues to grow steadily, especially in developing markets across Africa, Southeast Asia, and the Middle East.

High-quality cold rolled steel plate remains a key material for future industrial development.

Conclusion

Cold rolled carbon steel plate is a high-performance steel material that combines strength, precision, and excellent surface quality. It plays a crucial role in industries such as automotive, construction, appliances, furniture, and electrical equipment.

Whether you are a manufacturer, contractor, or steel trader, choosing the right cold rolled steel plate grade and specification ensures better product performance, lower processing cost, and longer service life.