Galvanized steel pipe

WhatsApp / Tel / Wechat

Still deciding? Get samples first, Contact US !

- Product Description

-

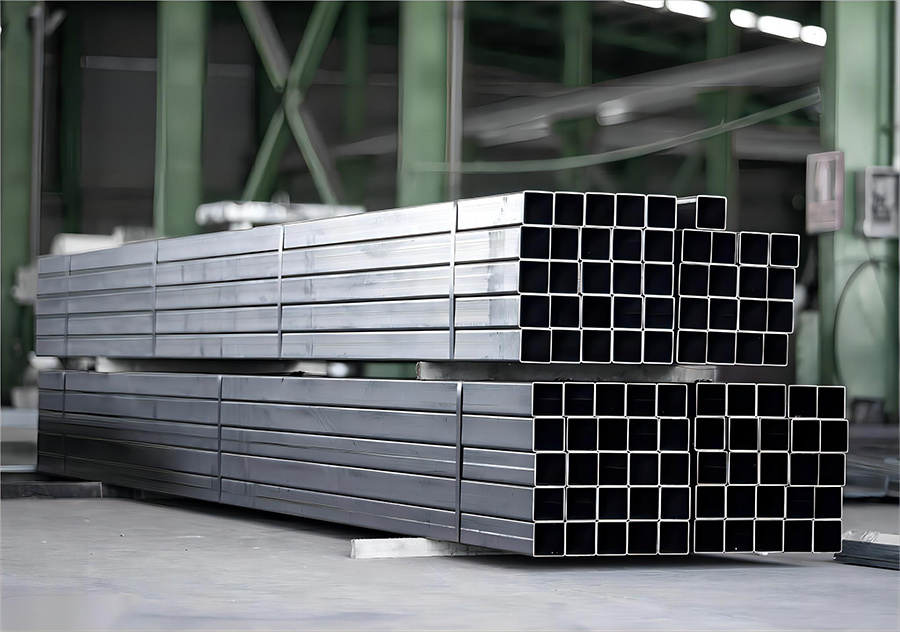

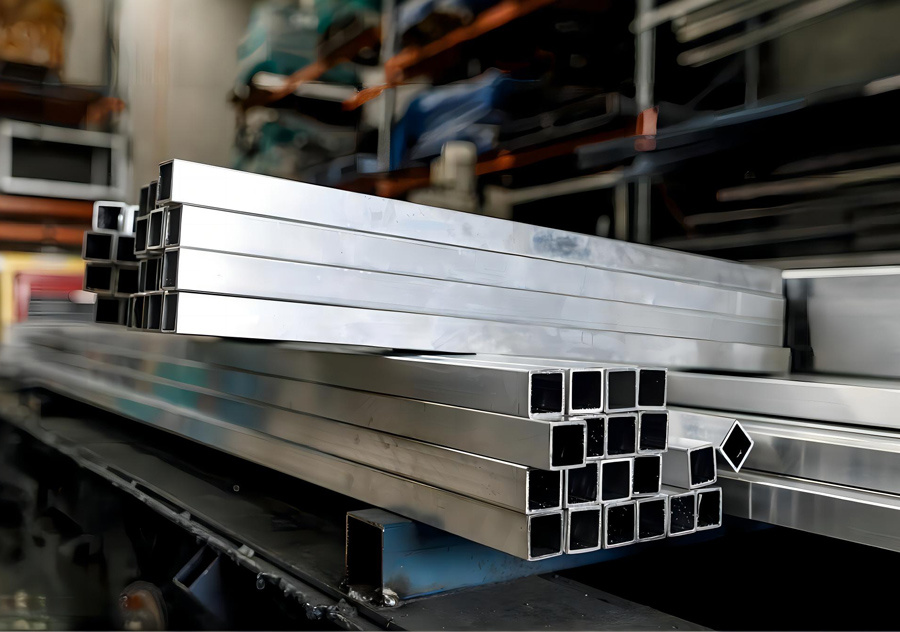

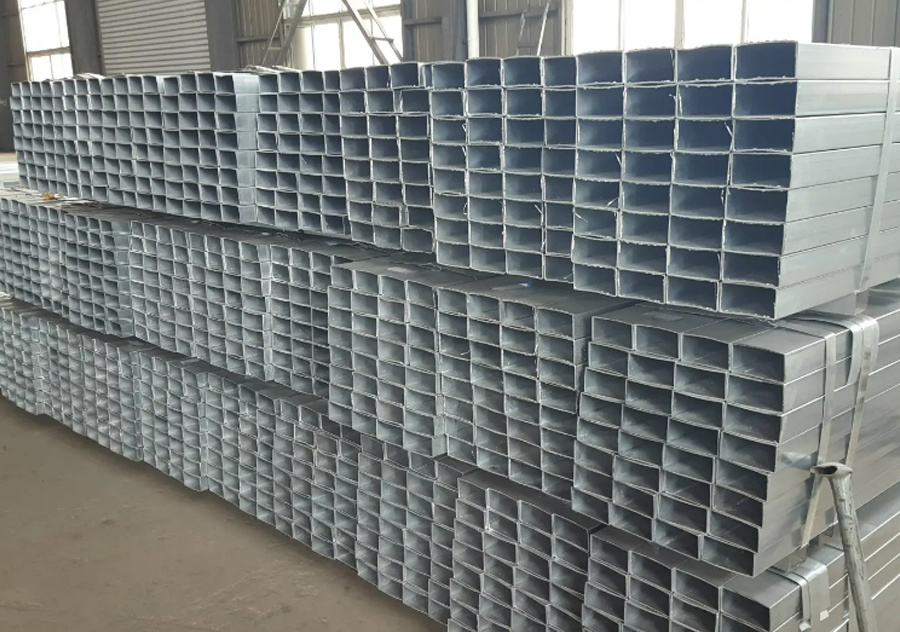

what is a galvanized steel pipe?

Galvanized steel pipe, also known as galvanized pipe, is a pipe product that forms an anti-corrosion protective layer through the hot-dip galvanizing process (zinc layer thickness 40-300μm), which is generally made of Seamless steel pipe or Welded tube, which has both the mechanical strength of steel and the corrosion resistance characteristics of zinc layer.

Shineyond Group mainly provides galvanized square pipes and round pipes, the products use hot-dip plating process to ensure that the zinc layer is firmly adhered to, and the service life is 3-5 times longer than that of ordinary steel pipes, especially suitable for outdoor and humid environments such as water supply and drainage systems, construction scaffolding, agricultural irrigation, etc.

At the same time, it provides value-added services such as customized cutting and threading, and attaches the original factory warranty, which is a cost-effective anti-corrosion pipeline solution.

Common materials

The main materials of galvanized steel pipe are: Q195, Q235, Q345 grades, of which Q235 and Q345 are the more common grades.

Galvanized round steel pipe dimensions

Type

Outer diameter

Wall thickness

Zinc content

length

MOQ

Packing

Delivery time

Round Pipe

20mm;25mm;32mm;40mm;

48mm;60mm;76mm;89mm;

108mm;114mm;133mm;

159mm;165mm;219mm;

1mm-6.25mm

electro:10-50g/m²

Hot dipped:50-600g/m²

6m-12m or customized

30tons

Bundle or

bulk

7-30 days

Galvanized steel pipe size chart

DN

Size

(inches)

Outer diameter

(MM)

Wall thickness

(MM)

Weight

(KG/M)

DN15

1/2

21.3

2.8

1.357

DN20

3/4

26.9

2.8

1.76

DN25

1

33.7

3.2

2.554

DN32

1-1/4

42.4

3.5

3.56

DN40

1-1/2

48.3

3.5

4.10

DN50

2

60.3

3.8

5.607

DN65

2-1/2

76.1

4.0

7.536

DN80

3

88.9

4.0

8.88

DN100

4

114.3

4.0

11.53

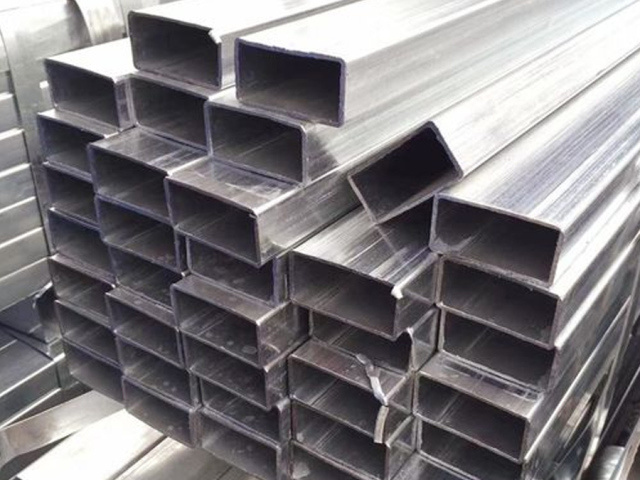

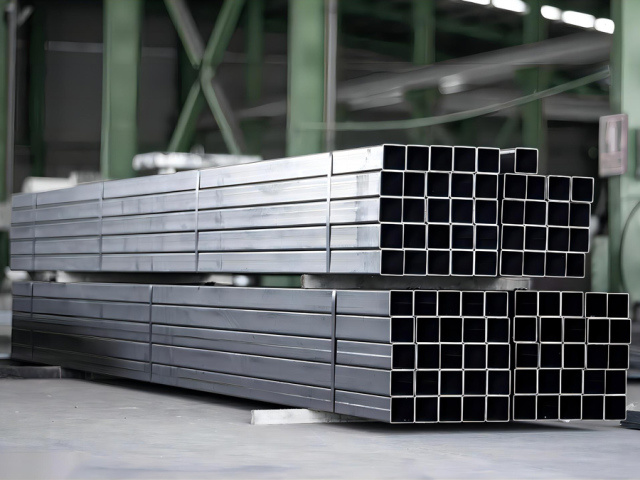

Galvanlzed Square steel pipe Specification size

Type

Outer diameter

Wall thickness

length

MOQ

Packing

Delivery time

Square pipe

10mm-200mm

0.5mm-9mm

6m-12m or customized size

30tons

Bundle or bulk

7-30days

Galvanized steel pipe Advantages

1. Excellent corrosion resistance

The zinc coating provides excellent protection against rust and corrosion, significantly extending the service life of the steel pipe even in harsh environments.

2. Aesthetic quality

We produce galvanized steel pipe with a smooth, brilliant surface finish that provides both functional performance and visual appeal in applications where appearance is paramount.

3. Excellent processability

The pipes are designed for ease of fabrication and can be easily cut, bent and welded without compromising their structural integrity, ensuring an efficient installation and construction process.

4. Long-lasting and durable

The combination of corrosion resistance and mechanical strength makes these pipes ideal for long-term use in demanding industrial and construction areas.

5. Wide range of uses

Suitable for both structural and decorative uses, they meet a wide range of requirements while maintaining consistent quality and reliability.

Production Process

The manufacturing method of black pipe (furnace welding or electric welding) is selected by the manufacturer. Galvanizing is to make the molten metal react with the iron matrix to produce an alloy layer, so that the matrix and the coating are combined. Galvanizing adopts hot dip galvanizing method and cold galvanizing method.

① Hot dip galvanizing is to pickle the steel pipe first. In order to remove the iron oxide on the surface of the steel pipe, after pickling, it is cleaned in an ammonium chloride or zinc chloride aqueous solution or a mixed aqueous solution of ammonium chloride and zinc chloride, and then sent to the hot dip galvanizing tank.

Hot-dip galvanizing: black parts inspection → hanging → degreasing → rinsing → pickling → cleaning → dipping plating agent → hot air drying → hot dip galvanizing → internal and external blowing → cooling → passivation and rinsing → unloading → inspection, trimming → typing and marking → packaging, storage and transportation.

② Cold galvanizing is electrogalvanizing. It uses electrochemical method to use zinc ingot as anode. Zinc atoms lose electrons and become ions to dissolve in the electrolyte. Steel material is used as cathode. Zinc ions get electrons on steel and are reduced to zinc atoms and deposited on the surface of steel, so as to form a uniform, dense and well-bonded metal or alloy deposition layer.

Electrogalvanizing: galvanized strip → unwinding → stretching → coiling → welding → scraping → passivation and rinsing → zinc supplementation → shaping → typing and marking → cutting → packaging → drying → weighing.

Galvanized steel pipe Application

1. Construction & Infrastructure

Widely used in buildings, pipelines, and bridges for superior corrosion resistance in harsh environments.

2. Water & Fluid Transport

Ideal for municipal water systems and industrial pipelines, safely conveying water, oil, gas, and chemicals.

3. Structural Frameworks

Provides reliable support as columns, beams, and frames in commercial and industrial structures.

4. Furniture Manufacturing

Popular for durable, aesthetically pleasing furniture frames and supports.

5. Industrial Applications

Versatile solution for agricultural, manufacturing, and equipment support needs.

Reliable galvanized steel pipe manufacturers

As a leading manufacturer of high-quality galvanized steel pipes, Shineyond Group ensures durability, corrosion resistance, and superior performance for various industrial and construction applications.

Why Choose Shineyond Group?

✅ Premium Materials – Made from high-grade steel with uniform zinc coating for enhanced protection.

✅ Advanced Manufacturing – Precision welding, hot-dip galvanization, and strict quality control.

✅ Wide Range of Products – Available in multiple sizes, thicknesses, and specifications.

✅ Competitive Pricing – Cost-effective solutions without compromising quality.

✅ Global Standards Compliance – Meets ASTM, DIN, JIS, and GB standards.

Galvanized steel pipe

WhatsApp / Tel / Wechat

Contact us via email

Still deciding? Get samples first, Contact US !

Products Category

Tag list

Galvanized steel pipe

Galvanized round steel pipe

Hot dipped galvanized steel pipe

GI steel pipe

Galvanized iron pipe

Sliver square steel pipe

Hot dipped galvanized square steel pipe

GI square steel pipe

Inquire Now

Note: Please leave your email address, our professionals will contact you as soon as possible!