Seamless Steel Pipe Manufacturer

WhatsApp / Tel / Wechat

Still deciding? Get samples first, Contact US !

View similar products

- Product Description

-

what is a Seamless steel pipe?

Seamless steel pipe is a high-performance tubular product manufactured through a precision extrusion or rotary perforation process that eliminates the need for welding, ensuring superior strength and reliability for demanding industries.

The seamless steel pipes produced by Shineyond Group are made of high-quality carbon steel such as 10, 20, 30, 35, 45, low-alloy structural steel such as 16Mn, 5MnV or alloy steel such as 40Cr, 30CrMnSi, 45Mn2, 40MnB, and are manufactured by hot rolling or cold rolling process.

Seamless construction eliminates weld weaknesses, provides excellent pressure control (rated up to 300+ bar) and uniform mechanical properties throughout the tube body, making it the best choice for high-pressure oil/gas transfer, power plant boilers, hydraulic systems, and critical process piping.

Seamless steel pipe Process

① After quality inspection, hot-rolled seamless carbon steel pipe must be strictly hand-selected by staff, and the surface must be oiled after quality inspection, followed by multiple cold drawing tests. After hot rolling, perforation tests must be carried out. If the perforation diameter is too large, straightening and correction must be carried out. After straightening, it is conveyed to the flaw detector by the conveyor for flaw detection, and finally labeled, arranged in specifications, and placed in the warehouse.

② When producing cold-rolled carbon steel seamless pipe, the tube blanks must first be subjected to three-roll continuous rolling, and then a sizing test must be carried out after extrusion. If there is no response crack on the surface, the round tube must be cut by a cutting machine and cut into a blank with a length of about one meter. Then enter the annealing process. Annealing requires pickling with acidic liquid. When pickling, pay attention to whether there are a lot of bubbles on the surface. If there are a lot of bubbles, it means that the quality of the steel pipe does not meet the corresponding standards. In appearance, the cold-rolled seamless steel pipe is shorter than the hot-rolled seamless steel pipe. The wall thickness of the cold-rolled seamless steel pipe is generally smaller than that of the hot-rolled seamless steel pipe, but the surface looks brighter than the thick-walled seamless steel pipe, the surface is not too rough, and the diameter does not have too many burrs.

Pipe blank--inspection--peeling--inspection--heating--piercing--pickling--grinding--lubrication and air drying--welding head--cold drawing--solution treatment--pickling--pickling passivation--inspection--cold rolling--degreasing--cutting head--air drying--internal polishing--external polishing--inspection--marking--finished product packaging

Common materials

Seamless steel pipes are usually made of high-quality carbon steels such as 10, 20, 30, 35, 45, low-alloy structural steels such as 16Mn, 5MnV, or alloy steels such as 40Cr, 30CrMnSi, 45Mn2, 40MnB, and are made through hot rolling or cold rolling processes.

Seamless steel pipe Specification

Outer diameter

Wall thickness

length

MOQ

Packing

Delivery time

5mm-630mm

1mm-90mm

6m-12m OR customized size

30tons

Bundling

Packaging

Oil-coated bundling

Or oil-coated packing

30days

Common size

Outer diameter: 8mm-510mm; wall thickness: 1mm-90mm.

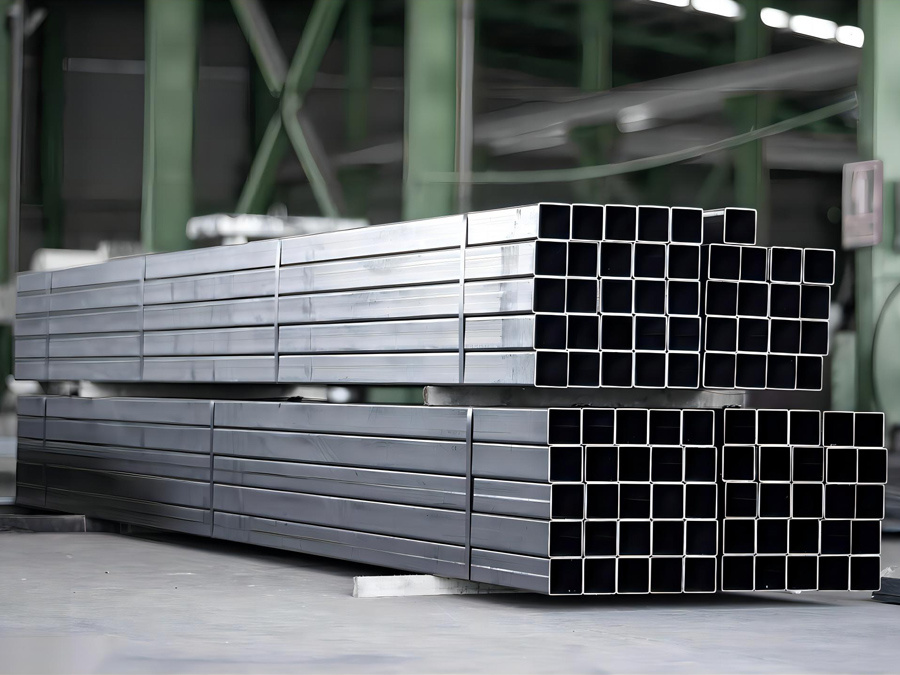

Seamless steel pipe Advantages

1. The seamless steel pipe we produce has excellent structural performance and outstanding bending resistance while maintaining a lightweight design to ensure strength and efficiency in applications.

2. The pipes are carefully designed for durability and excellent corrosion resistance, suitable for use in high temperature, high pressure and other harsh environments where reliability is critical.

3. Seamless carbon steel pipe is seamlessly welded and precision-manufactured, offering leak-proof performance and long-lasting integrity, reducing maintenance needs and downtime.

4. With high-precision surface treatment and consistent quality, it is suitable for a wide range of industrial uses from fluid delivery pipes to precision mechanical parts.

5. Versatile and reliable, it is an ideal choice for industries that require strong performance under harsh conditions, and is backed by strict quality control and excellent workmanship.

Seamless steel pipe Application

seamless steel pipe made of general-purpose materials are primarily used for conveying fluids, such as oil, natural gas, coal gas, water, and certain solid materials. They are also widely used in the manufacture of structural and mechanical parts, such as oil drilling pipes, automobile drive shafts, bicycle frames, and steel scaffolding used in construction. Using steel pipes in the manufacture of annular parts can improve material utilization, simplify manufacturing processes, and save material.

seamless carbon steel pipe made of special materials are mainly used as petroleum geological drilling pipes, chemical cracking pipes, boiler pipes, bearing pipes and high-precision structural steel pipes for aviation.

Reliable seamless steel pipe manufacturer

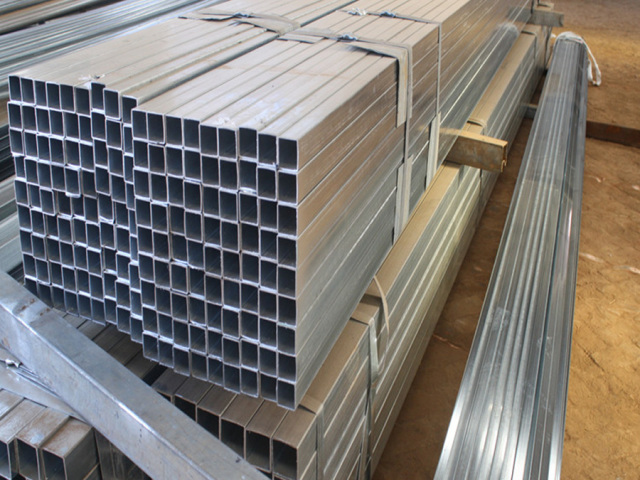

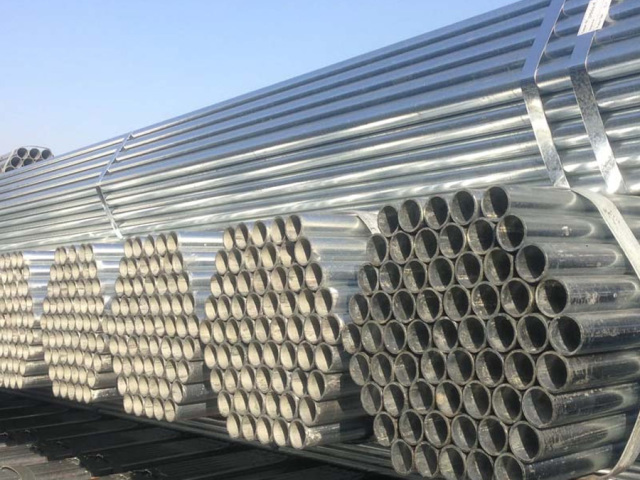

Shineyond Group is a seamless steel pipe supplier, mainly providing seamless square steel pipe and seamless round steel pipe, and providing additional processing, including heat treatment (normalizing/Q&T), threading and anti-corrosion coating (3PE, FBE), to meet specific project requirements in the fields of energy, chemical and mechanical engineering.

Seamless Steel Pipe Manufacturer

WhatsApp / Tel / Wechat

Contact us via email

Still deciding? Get samples first, Contact US !

Products Category

Tag list

Seamless steel pipe

Seamless steel tube

Seamless round steel pipe

Shaped seamless steel pipe

Galvanized seamless steel pipe

Seamless Steel Pipe

Inquire Now

Note: Please leave your email address, our professionals will contact you as soon as possible!

Related Products