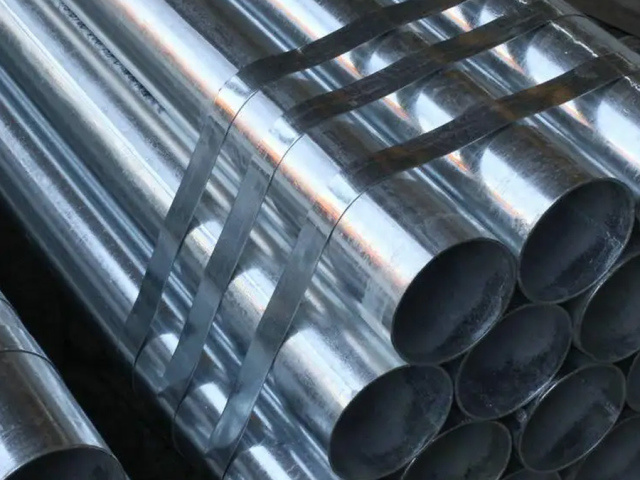

Welded tube

WhatsApp / Tel / Wechat

Still deciding? Get samples first, Contact US !

- Product Description

-

what is a Welded tube?

Shineyond Group produces Welded tube with precision hollow structural components manufactured through high-frequency (HF) or submerged arc welding (SAW) processes, mainly round and square profiles. Round welded steel pipe is a steel pipe welded by crimping and forming a steel plate or steel strip, and the general fixed length is 6 meters. Welded square pipes are square pipes welded from steel plates or steel strips after being crimped. It can also be referred to as welded pipes for short.

Excellent weld integrity combines for structural frames, mechanical systems, and fluid transfer applications. In addition, we offer value-added services, including custom cutting, bending, and post-weld heat treatment, to make our welding tube suitable for construction, automotive, oil/gas (API certified), and construction applications.

Welded tube Process

Welded pipes are formed from hot-rolled coils into smooth cylindrical shapes using a forming machine. The edges of the pipe blank are heated and melted by the skin and proximity effects of high-frequency current, or by arc combustion beneath a slag layer, before cooling and forming. Large-diameter or thicker welded pipes are typically made directly from the billet, while smaller and thin-walled pipes can be welded directly from steel strip. Afterwards, simple polishing and brushing are performed to complete the pipe.

Raw material uncoiling-leveling-end shearing and welding-loop-forming-welding-removal of internal and external weld beads-pre-correction-induction heat treatment-sizing and straightening-eddy current detection-cutting-water pressure inspection-pickling-final inspection (strict control)-packaging-shipping.

Common materials

The main materials of welded tube are:Q195, Q235A, Q235B, Q345, 20#, etc.

Round welded steel pipe specification

Outer diameter

Wall thickness

length

MOQ

Packing

Delivery time

20mm;25mm;32mm;40mm;

48mm;60mm;76mm;89mm;

108mm;114mm;133mm;

159mm;165mm;219mm;

1mm-6.25mm

4m-12m or other length for you requirement

30tons

Bundles or bulk

7-30days

Common size

Schedute number

Nominal Size

(inches)

Outer diameter

(mm)

Wall thickness

(mm)

Weight(black pipe)

(kg/m)

40

1/2

21.3

2.77

1.27

40

3/4

26.7

2.87

1.69

40

1

33.4

3.38

2.50

40

1-1/4

42.2

3.56

3.39

40

1-1/2

48.3

3.68

4.05

40

2

60.3

3.91

5.44

40

2-1/2

73.0

5.16

8.63

40

3

88.9

5.49

11.29

40

4

114.3

6.02

16.07

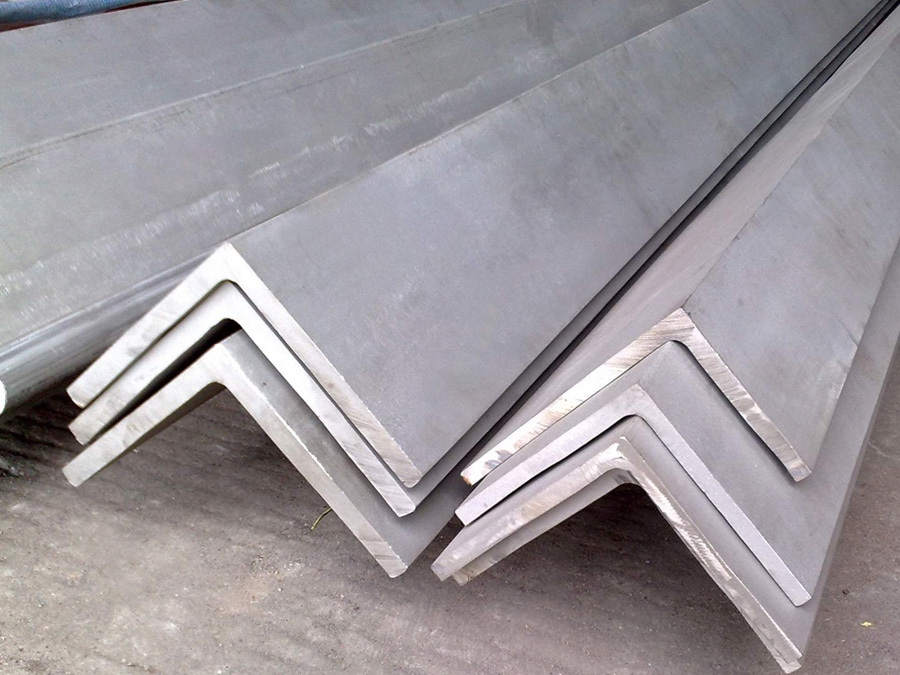

Square welded steel pipe specification specification

Outer diameter

Wall thickness

length

MOQ

Packing

Delivery time

10mm-200mm

0.5mm-9mm

6m-12m or other customized size

30tons

Bundles

Or bulk

7-30days

Common size

Size

(mm)

Length

(m)

Weight

(kg)

Packing

(pcs/bundle)

30×50×1.5

6

1120

104

30×50×1.7

6

1190

104

30×50×1.8

6

1330

104

30×50×2.0

6

1380

104

30×50×2.2

6

1640

104

30×50×2.5

6

1820

104

40×60×1.5

6

910

70

40×60×1.7

6

1030

70

40×60×1.8

6

1095

70

40×60×2.0

6

1200

70

40×60×2.2

6

1274

70

40×60×2.5

6

1480

70

40×40×1.5

6

1088

100

40×40×1.7

6

1226

100

40×40×1.8

6

1300

100

40×40×2.0

6

1431

100

40×40×2.2

6

1566

100

40×40×2.5

6

1766

100

50×50×1.5

6

860

64

50×50×1.7

6

968

64

50×50×1.8

6

1016

64

50×50×2.0

6

1038

64

50×50×2.2

6

1268

64

50×50×2.5

6

1386

64

40×80×1.5

6

830

50

40×80×1.7

6

918

50

40×80×1.8

6

896

50

40×80×2.0

6

1068

50

40×80×2.2

6

1178

50

40×80×2.5

6

1354

50

100×150×4.5

6

1224

12

100×150×4.75

6

1290

12

100×150×5.5

6

1486

12

100×150×5.75

6

1580

12

100×150×7.5

6

1988

12

100×150×7.75

6

2054

12

100×200×4.5

6

986

8

100×200×4.75

6

1040

8

100×200×5.5

6

1980

8

100×200×5.75

6

1248

8

100×200×7.5

6

1610

8

100×200×7.75

6

1660

8

150×200×4.75

6

914

6

150×200×5.5

6

1053

6

150×200×5.75

6

1100

6

150×200×7.5

6

1430

6

150×200×7.75

6

1465

6

150×200×8.5

6

1618

6

150×150×4.5

6

1110

9

150×150×4.75

6

1178

9

150×150×5.5

6

1348

9

150×150×5.75

6

1410

9

150×150×7.5

6

1812

9

150×150×7.75

6

1890

9

Welded tube Advantages

1. High strength and reliability:

Advanced welding technology (such as high-frequency induction welding or submerged arc welding) is used to ensure that the weld and the base material reach the same strength, ensuring the structural integrity of the steel pipe under high pressure and high load conditions.

2. Precision size control:

The cold rolling forming process can achieve a wall thickness accuracy of ±0.2mm and an outer diameter tolerance that can reach ASTM A500 standards, making it particularly suitable for size-sensitive prefabricated buildings and machinery manufacturing.

3. Diversified product portfolio:

We can produce products in a full range of sizes with diameters from 6mm to 2540mm, and support customized wall thickness, material (Q235B to X80 grade pipeline steel) and special coating treatments (galvanizing, epoxy resin, etc.).

4. Production efficiency advantage:

The continuous forming and welding production line speed can reach 60m/min, which is 3-5 times more efficient than traditional seamless pipe rolling and can meet the delivery needs of large-volume orders.

5. Full life cycle cost optimization:

Through online eddy current testing, ultrasonic testing and other quality control measures, the product service life is extended by more than 30%, significantly reducing the frequency of maintenance and replacement.

Welded pipes Applications

The various uses of welded steel pipes

Our high-quality welded steel pipes are used across a wide range of industries, including fluid transport, structural applications, and industrial uses. These durable pipes are essential components of municipal water systems, agricultural irrigation, and gas distribution networks (including coal, steam, and liquefied petroleum gas).

Industrial-grade performance

From mining operations to machinery manufacturing, they are used in ventilation systems, material handling equipment, and machine components. They are also widely used in furniture production and port machinery, and are available in customizable specifications to meet specific industrial needs. We offer a wide range of sizes and thicknesses, combining durability and cost-effectiveness for a wide range of industrial applications.

Structural excellence to meet architectural needs

In construction and infrastructure projects, our welded pipes provide reliable structural support for applications such as piling pipes, bridge components, and building frames. They are also essential for temporary structures like scaffolding systems, as well as permanent installations in ports, roads, and agricultural buildings. The excellent strength-to-weight ratio and dimensional accuracy of our welded pipes ensure long-lasting performance in demanding structural applications.

Reliable welded tube supplier

Shineyond Group is a leading manufacturer of welded tube. We provide high-quality, precision-made steel pipes for a variety of industrial applications. Manufactured using advanced technology and subject to strict quality control, we ensure our products are durable, perform well, and meet international standards.

Why Choose Us?

✅ Premium Quality – Made from high-grade steel with superior weld integrity and corrosion resistance.

✅ Wide Range – Available in various sizes, thicknesses, and specifications for fluid transport, structural, and industrial uses.

✅ Custom Solutions – Tailored to meet specific project requirements, including material grade, diameter, and surface finish.

✅ Reliable Supply – Consistent production capacity and on-time delivery to support your operations.

✅ Certified Excellence – Compliant with ISO, ASTM, and other industry standards for guaranteed performance.

Welded tube

WhatsApp / Tel / Wechat

Contact us via email

Still deciding? Get samples first, Contact US !

Products Category

Tag list

Welded steel pipe

Welded round steel pipe

Black steel pipe

Spiral welded steel pipe

Black iron round pipe

Square welded steel pipe

Square steel tube

Square black steel pipe

Hollow square steel pipe

Black iron square pipe

Inquire Now

Note: Please leave your email address, our professionals will contact you as soon as possible!

Related Products