Galvalume Steel Coil | GL Steel Coil Suppliers

WhatsApp / Tel / Wechat

Still deciding? Get samples first, Contact US !

View similar products

- Product Description

-

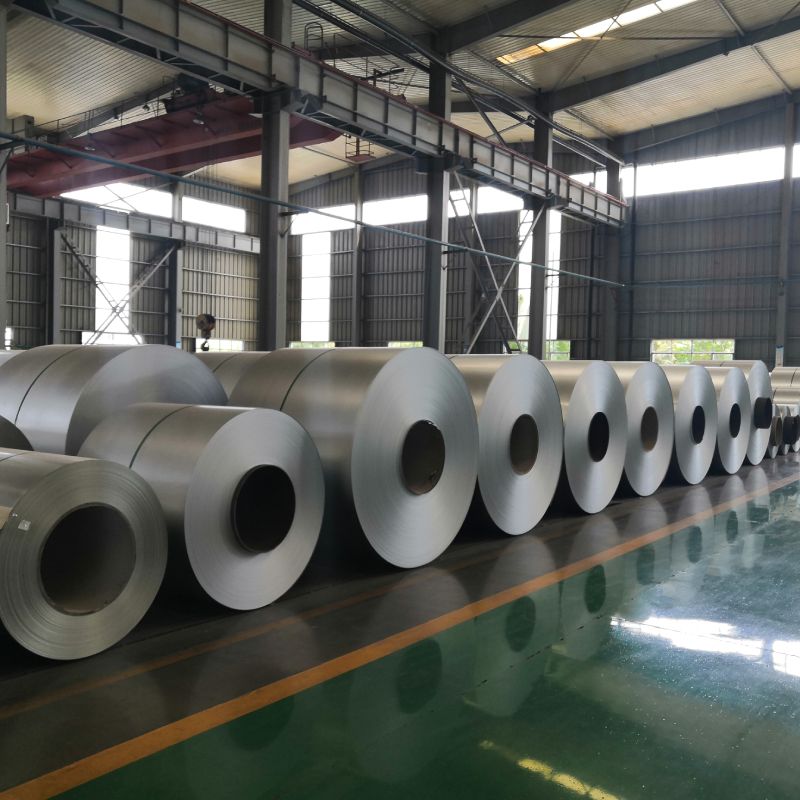

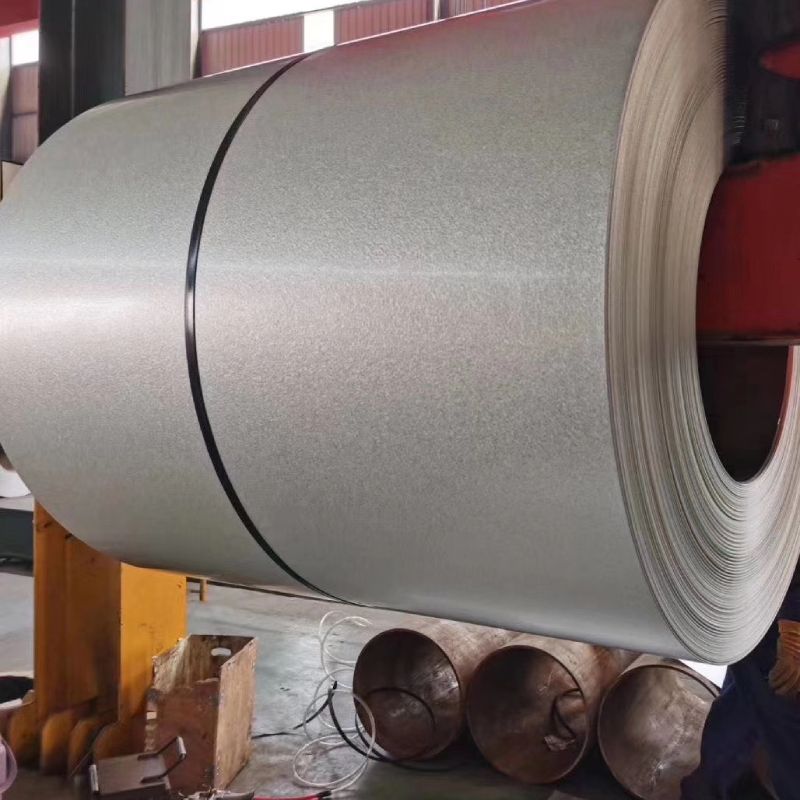

What Is Galvalume Steel Coil?

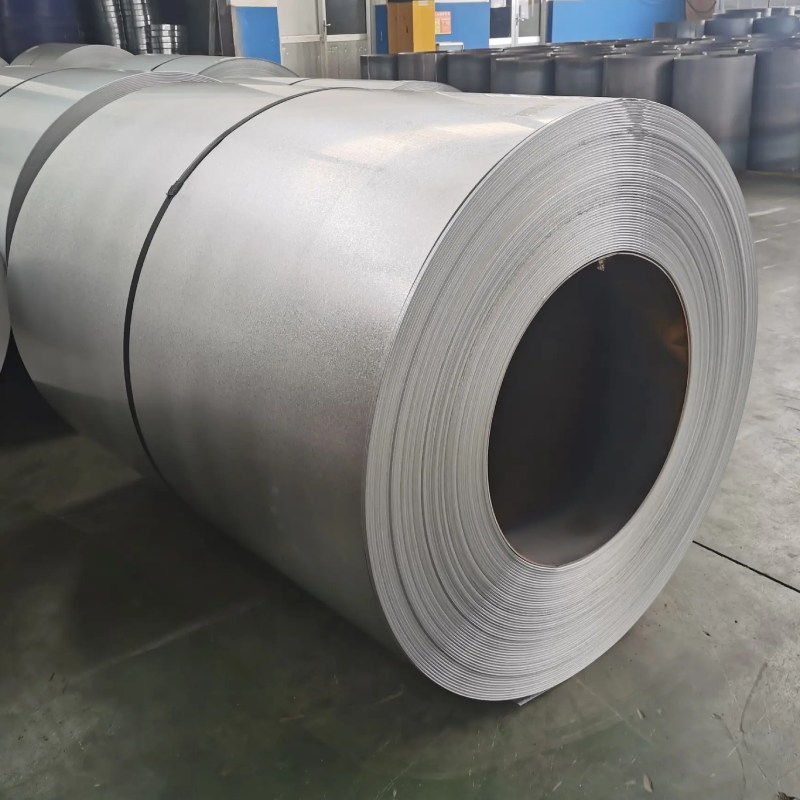

Galvalume steel coil is flat steel coated with a zinc-aluminum alloy (GL coating), combining the corrosion protection of zinc with the durability of aluminum. It is widely used in roofing, wall cladding, industrial equipment, and manufacturing applications.

At Shineyond Group, all Galvalume coils are produced to meet international standards, ensuring consistent thickness, coating weight, and mechanical properties.

Galvalume Steel Coil Specification

Material

Aluminium-zinc alloy

Standard

ASTM A653/A653M-99, ASTM A90/A90M, ASTM D2092, JIS SGCC, etc

Grade

DC51D AZ、DC52D AZ DC53D AZ、DC54D AZ、DC56D AZ、S250GD AZ、S350GD AZ、S550GD AZ

Thickness

0.12-2.0mm

Width

700-1250mm

Zinc Layer

30-200g/㎡

Inner Diameter

508/610mm

Coil Weight

3-6tons or according to customer requirements

Surface Treatment

oiled, passivated or chrome-free passivated, passivated + oiled

MOQ

None

Delivery Time

In stock

Package

Standard export package

Types / Grades of Galvalume Coil

AZ150 – Standard corrosion protection, cost-effective

AZ185 – Enhanced coating for harsh environments

Custom Coatings – Tailored for specific industrial or construction projects

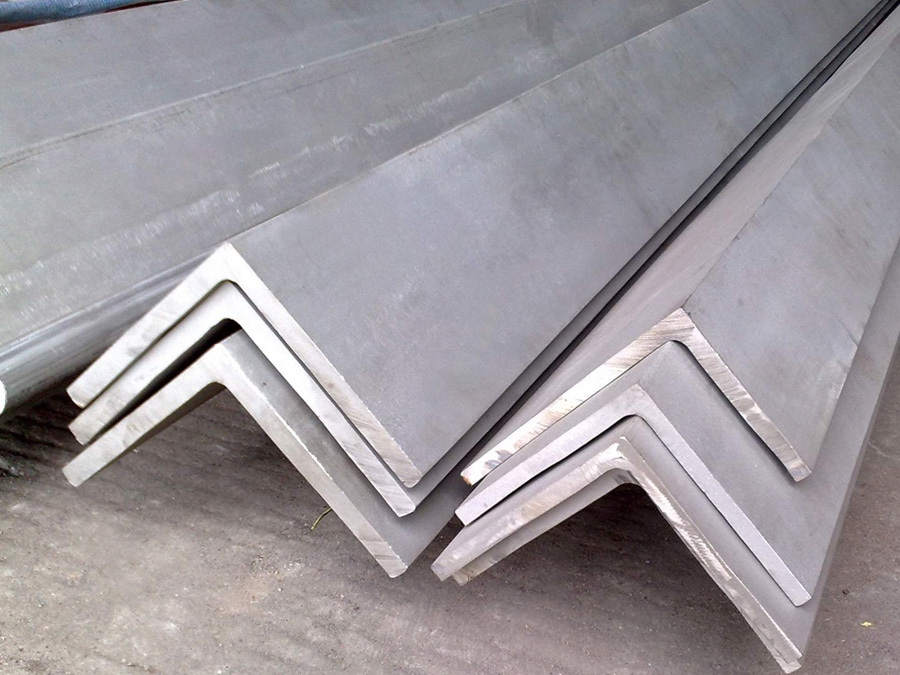

Applications of Galvalume Steel Coil

Roofing sheets and wall cladding

Industrial buildings, warehouses, and sheds

HVAC ducts and piping

Automotive panels and components

Agricultural structures

Electrical and appliance manufacturing

Why Choose Shineyond Group's Galvalume Steel Coil

Premium quality Galvalume coils with strict tolerance control

Multiple grades and coatings for different environments

Stable export supply for global projects

Professional technical support for construction and industrial buyers

Buyer’s Checklist: How to Choose the Right Galvalume Coil

Environmental Conditions: Coastal, industrial, or humid areas?

Coating Thickness: AZ150 vs AZ185 depending on exposure

Width & Coil Weight: Compatible with processing equipment

Budget vs Performance: Choose higher coating weight for longer service life

FAQ – Galvalume Steel Coil

Q1: What is Galvalume steel coil used for?

It is mainly used for roofing, cladding, ducting, appliances, and industrial manufacturing.

Q2: Can Shineyond Group customize GL steel coil?

Yes, thickness, width, coating weight, and surface finish can be tailored to project requirements.

Q3: What is the difference between Galvalume and galvanized steel?

Galvalume combines zinc + aluminum for superior corrosion resistance and heat durability.

Looking for reliable GL steel coil suppliers?

Contact Shineyond Group today for a customized quote, technical consultation, or product samples tailored to your project.

Galvalume Steel Coil | GL Steel Coil Suppliers

WhatsApp / Tel / Wechat

Contact us via email

Still deciding? Get samples first, Contact US !

Products Category

Tag list

Galvalume steel coil

Galvalume coils

Pre-Painted Aluminum Zinc Plated Steel Coil

Galvalume roofing coil

GL Steel Coil

Get a Free Quote

Note: Please leave your email address, our professionals will contact you as soon as possible!