Galvanized Steel Coil | GI Coil Supplier

WhatsApp / Tel / Wechat

Still deciding? Get samples first, Contact US !

- Product Description

-

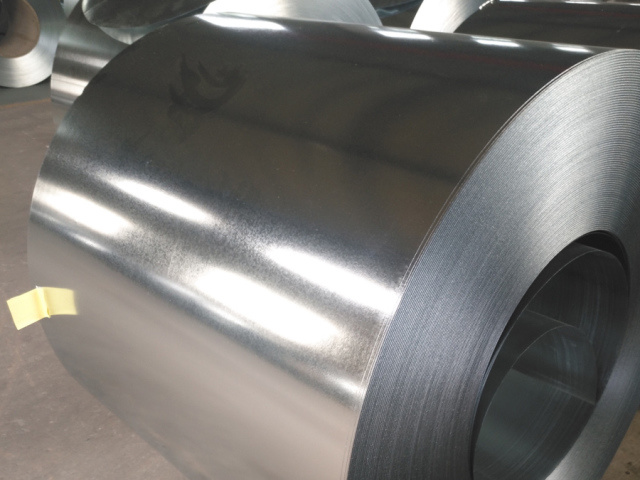

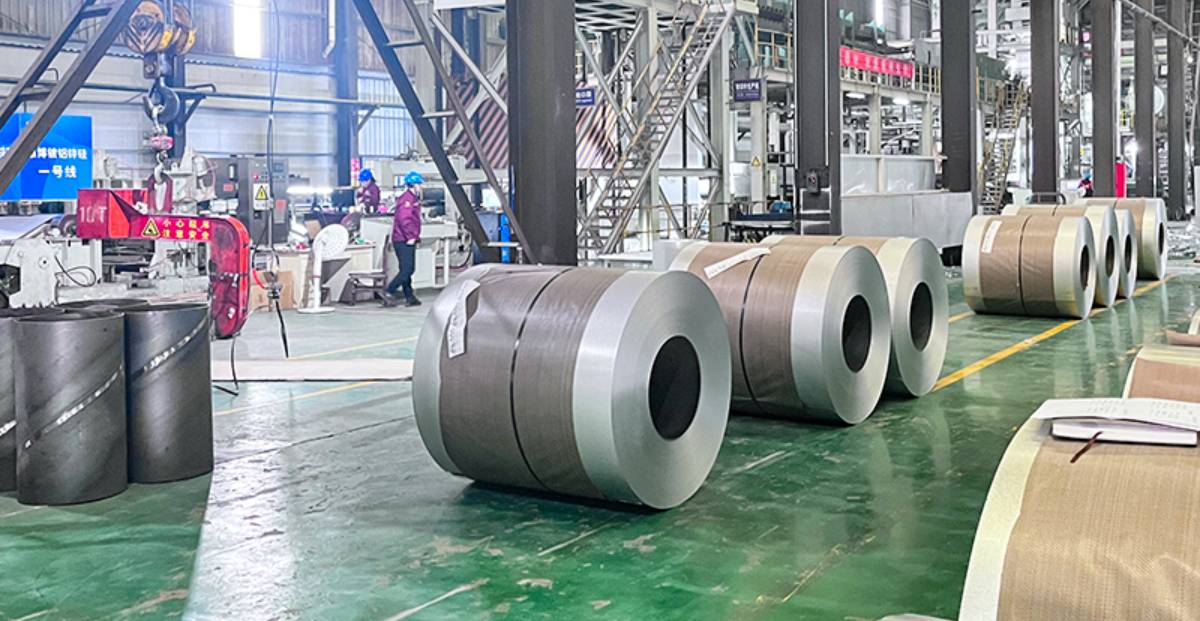

What Is Galvanized Steel Coil?

Galvanized steel coils are made by applying a zinc layer to the surface to prevent corrosion and improve durability. It is commonly used in roofing, wall cladding, pipe manufacturing, and industrial equipment.

All gi coil of Shineyond Group meet international standards and can be customized according to customer needs, providing one-stop solutions.

Galvanized Steel Coil Specification

Material

Steel, Zinc Alloy

Standard

SGCC, ASTM A653/653M, ASTM A36, JISG302, etc

Grade

DX51D, DX52D, DC51D, DX54D, SGCC, SGCD, SECC, etc

Thickness

0.12-3.50mm

Width

100-1250mm

Zinc Layer

30-275g/㎡

Inner Diameter

508/610mm

Coil Weight

3-4tons, 4-6tons or according to customer requirements

Spangle

no spangle, minimized spangle, maximum spangle, regular spangle

Surface Treatment

oiled, passivated or chrome-free passivated, passivated + oiled

MOQ

None

Delivery Time

In stock Package

Standard export package

Types / Grades of Galvanized Coil

Hot-Dip Galvanized (HDG) Coil – Robust zinc coating via immersion

Electro-Galvanized (EG) Coil – Thin, uniform coating for precise forming

Custom Coatings – Tailored to specific environmental or industrial needs

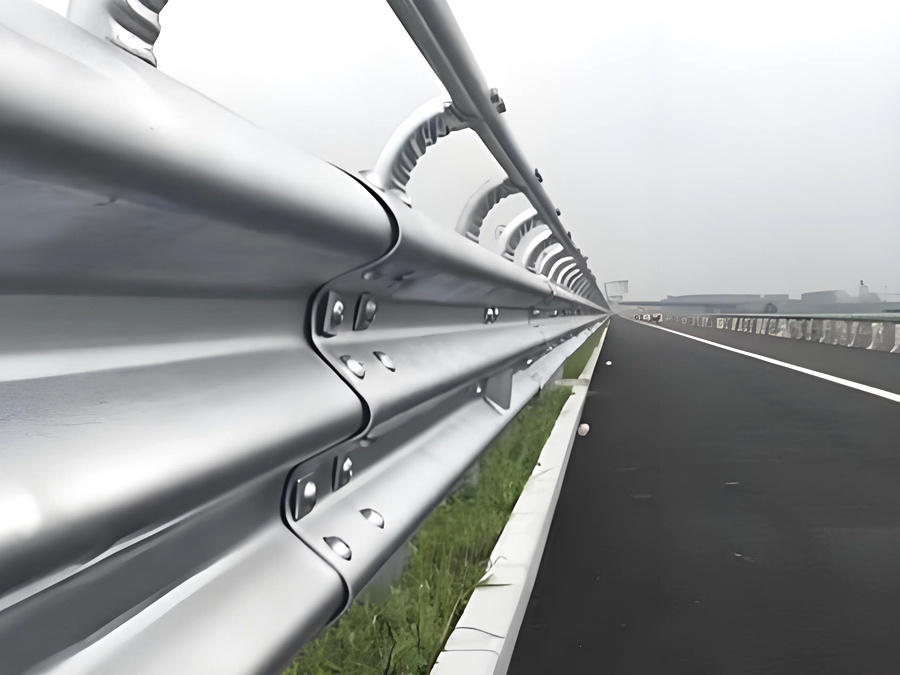

Applications of Steel Galvanized Coil

Roofing sheets and wall cladding

Industrial buildings, warehouses, and sheds

Pipe and tube manufacturing

Automotive panels and components

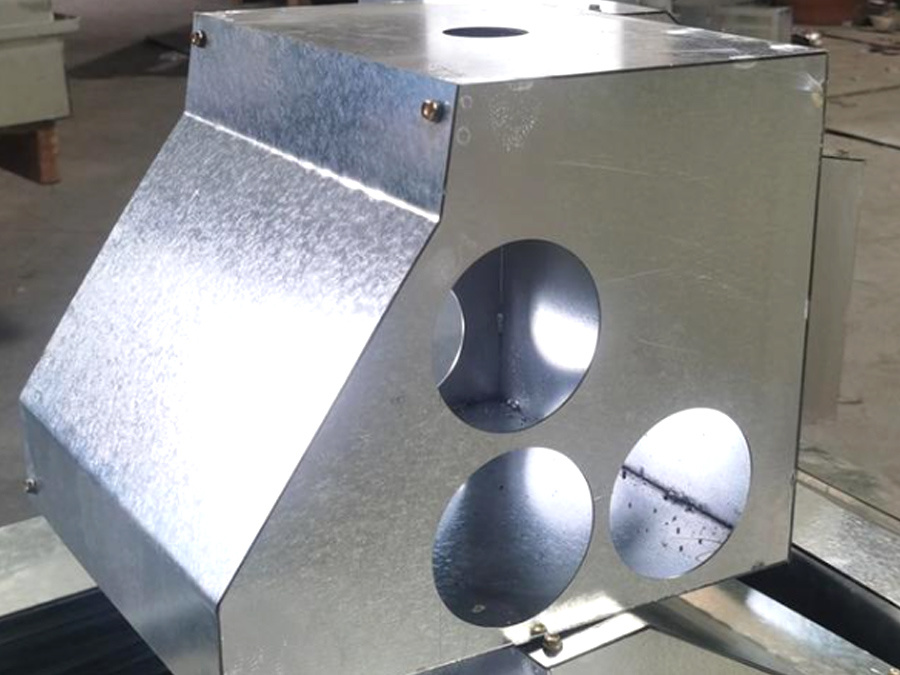

Electrical panels and appliances

Agricultural structures and machinery

Why Choose Shineyond Group's Galvanized Steel Coil

Premium quality GI coils with strict tolerance control

Multiple coating weights and steel grades

Stable long-term supply for international projects

Professional technical support for construction and industrial applications

Buyer’s Checklist: How to Choose the Right GI Coil

Environmental Conditions: Coastal, industrial, or humid areas?

Coating Thickness: Z30–Z275 depending on exposure

Width & Coil Weight: Compatible with processing equipment

Budget vs Performance: Higher coating weight = longer service life

FAQ – Galvanized Steel Coil

Q1: What is galvanized steel coil used for?

It is used for roofing, cladding, pipe/tube production, industrial equipment, and automotive components.

Q2: Can Shineyond Group customize GI coil specifications?

Yes, thickness, width, coating weight, and surface finish can all be customized.

Q3: How is GI coil different from Galvalume coil?

GI coil is zinc-coated only; Galvalume combines aluminum + zinc for superior corrosion resistance and heat durability.

Looking for reliable GI steel coil suppliers?

Contact Shineyond Group today for a customized quote, technical consultation, or product samples tailored to your project needs.

Galvanized Steel Coil Process

1. Pickling: The steel coil to be galvanized is put into the acid solution for pickling, mainly to remove oxides, oil stains and rust on the surface of the steel to ensure the galvanizing effect.

2. After cleaning and pickling, rinse the surface of the steel coil with water to remove residual acids and chloride ions and other harmful substances.

3. Pre-treatment: Put the cleaned steel coil into the pre-treatment tank, which will form a protective film on the surface of the steel, thereby enhancing the combination of the steel coil and the zinc solution and greatly improving the coating quality.

4. Baking: After pretreatment, it is dried for subsequent galvanization process.

5. Zinc dipping: The baked steel coil is immersed in molten zinc to form a zinc layer to avoid corrosion of the steel coil, and adjust the galvanization time and temperature according to the demand to achieve the required quality.

6. Cooling: After the galvanization process, wait for the steel coil to cool down to make the zinc layer solidify quickly.

7. Crimping: After cooling, the galvanized steel coil is crimped and tested for quality, mainly including coating thickness, adhesion and uniformity.

Galvanized Steel Coil | GI Coil Supplier

WhatsApp / Tel / Wechat

Contact us via email

Still deciding? Get samples first, Contact US !

Products Category

Tag list

Galvanized steel coil

Galvanized Steel Sheet In Coil

Galvanized Steel Sheet Roll

Galvanized Steel Coil For Roofing Sheet

Hot Dip GI Coil

Electro galvanized steel coil

GI Coil

Galvanized Coil

Get a Free Quote

Note: Please leave your email address, our professionals will contact you as soon as possible!