Hot Rolled vs Cold Rolled Steel: Key Differences Explained

When comparing cold rolled vs hot rolled, it’s important to understand that these are two major type of steel production methods. You may also see phrases like hot rolled vs cold rolled, hot vs cold rolled steel, hot rolled vs cold rolled steel, cold rolled steel vs hot rolled steel, hot rolled steel vs cold rolled steel, and cold rolled vs hot rolled steel—all describing the same comparison. Although the steel may start from the same raw material, the rolling method, temperature, and finishing steps create very different properties, affecting strength, surface finish, dimensional accuracy, and suitable applications.

Hot vs Cold Rolled Steel: Main Differences

Feature | Hot Rolled Steel | Cold Rolled Steel |

Surface | Rough, darker finish | Smooth, bright finish |

Dimensional Accuracy | Less precise | Extremely precise |

Strength | Good | Higher due to work hardening |

Cost | Lower | Higher due to additional processing |

Processing Temperature | Rolled above recrystallization temperature | Rolled at room temperature after cooling |

Applications | Structural steel, beams, channels, heavy machinery | Sheet metal, appliances, furniture, automotive parts |

It’s also common to see steel described as hot rolled steel cold rolled steel in discussions about manufacturing processes. This highlights that the steel may undergo both hot and cold rolling at different stages, depending on the desired properties.

What is Hot Rolled Steel

Hot rolled steel is processed at a temperature above the recrystallization temperature, making the metal soft enough to shape easily. During this process, steel passes through large rollers while still extremely hot. Because it is not cooled at room temperature in a controlled way, rolled steel is steel, but its final dimensions may vary slightly as it cools naturally.

Key Features of Hot Rolled Steel

1. Rough surface finish, often dark or with mill scale

2. Wider dimensional tolerances due to natural shrinkage

3. Lower cost compared to cold rolled steel

4. High strength suitable for structural components, such as beams, channels, plates, and general construction

Hot rolled steel is preferred for projects where appearance is not critical but volume and strength are important. Examples include building frames, industrial pipelines, and heavy machinery. Because the steel is shaped above the recrystallization temperature, it can form larger sections more efficiently than cold rolled alternatives.

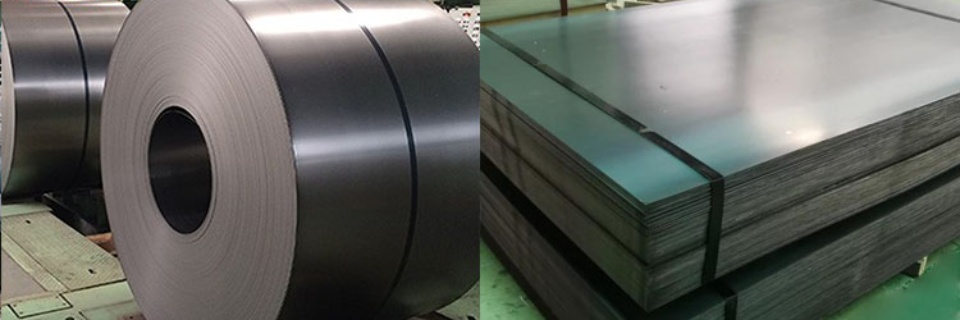

What is Cold Rolled Steel

Cold rolled steel begins as hot rolled material but undergoes additional processing. After cooling, it is rolled again with rollers at room temperature, often referred to as rolled and cold rolled steel. This process increases strength through work hardening, produces a smoother surface, and allows for much tighter dimensional tolerances.

During cold rolling, the metal may develop internal stress, which can be relieved through annealing if necessary. Cold rolling is sometimes referred to as rolled or cold or rolled or cold rolled, depending on context. It is widely used for applications that require precision, surface quality, and formability.

Key Features of Cold Rolled Steel

1. Smooth, bright, and uniform surface

2. Very precise dimensions and tighter tolerances

3. Higher strength due to work hardening

4.Ideal for sheet metal, furniture, automotive components, appliances, and other detailed fabrication

5. Commonly used in applications of cold rolled steel

Cold rolled steel allows manufacturers to create thinner, stronger, and cleaner components. While it is more expensive than hot rolled steel, the improved surface quality, strength, and precision make it indispensable for many industries.

Choosing Between Hot and Cold Rolled Steel

When deciding between hot rolled steel vs cold rolled steel, consider the following:

Choose hot rolled steel if:

Cost is a key factor

You need high-volume structural steel

Appearance is not a priority

Small dimensional variations are acceptable

Choose cold rolled steel if:

You require smooth sheet metal for painting, coating, or forming

Tight tolerances are essential

Strength and precision are important

The final product requires a clean, uniform appearance

Understanding whether to use rolled and cold or rolled steel is steel ensures that your project uses the most suitable material. The choice between hot and cold rolled steel often depends on both functional and aesthetic requirements.

Final Thoughts

Whether comparing cold rolled vs hot rolled, hot rolled vs cold rolled, or hot vs cold rolled steel, the differences are clear: hot rolled steel is economical, strong, and ideal for structural applications, while cold rolled steel is precise, smooth, and better for applications of cold rolled steel in sheet metal and finished products. By understanding these key differences, you can select the right steel based on cost, strength, finish, and project requirements.