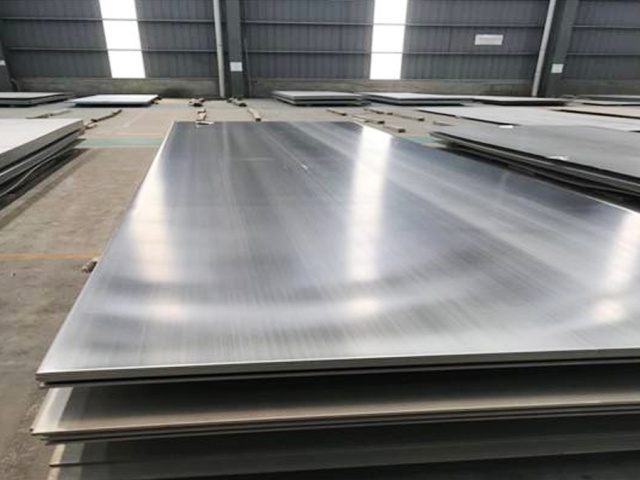

cold rolled steel sheet

WhatsApp / Tel / Wechat

Still deciding? Get samples first, Contact US !

View similar products

- Product Description

-

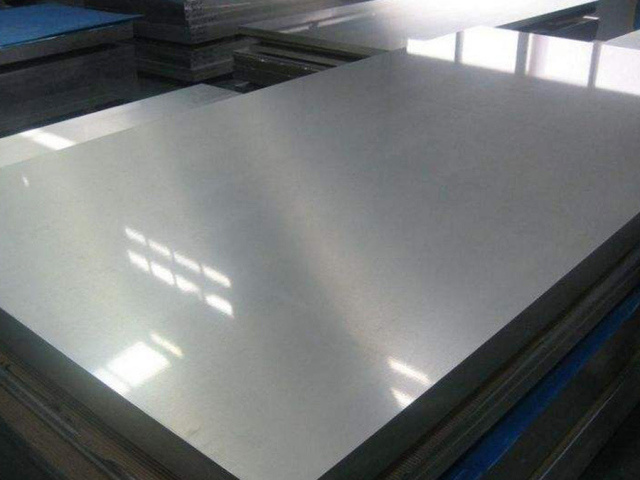

what is a Cold rolled steel sheet

Cold rolled steel sheet is processed by room temperature rolling, annealing and leveling process, which is a precision flat steel with a smooth and non-scale-free surface, high dimensional accuracy (thickness tolerance ±0.1mm), excellent strength and good formability. Compared with hot rolled sheet, after cold work hardening, it can greatly improve the hardness and mechanical properties, and can meet the needs of precision machining such as stamping, bending and deep drawing, and has been widely used in high-end fields such as automobile body parts, precision mechanical parts, elevator building materials and industrial equipment shells. Provide surface treatment solutions such as oiling and phosphating to effectively reduce subsequent processing processes.

Cold rolled steel sheet specifications

Thickness

0.2-4mm

Width

600-2000mm

Length

1200-6000mm

*Special specifications can be customized

Material

CDCM - SPCC (SPCD、SPCE、ST12、ST13、ST14、BLC、BLD、BUSD、BUFD、BSUFD

Cold rolled steel sheet advantages

1. Heat Resistance:Outperforms galvanized steel in high-temperature applications.

2. Thermal Reflectivity:Effectively reflects heat for thermal management.

3. Aesthetic Finish:Bright silver-white surface for visual appeal.

4. Processing Ease:Maintains formability and paintability like galvanized steel.

5. Welding Performance:Ensures strong, consistent welds.

Application

1. Automobile manufacturing - used for body panels, structural parts, etc., with high strength and formability;

2. Electronic products - as a shell material for precision electronic equipment, meeting lightweight requirements;

3. Rail transit - suitable for the manufacture of structural parts for high-speed rail, subway and other vehicles;

4. Aerospace - used for aircraft interior parts and auxiliary components;

5. Precision instruments - meet the high precision requirements of medical equipment, optical instruments, etc.

6. Food packaging - tinplate is used in food containers such as cans and beverage cans.

Production Process

Cold rolling eliminates heating during production, avoiding common hot-rolling defects like pitting and oxide scale formation, resulting in superior surface quality and finish. Additionally, cold-rolled products offer exceptional dimensional accuracy while meeting specialized performance requirements, including enhanced electromagnetic properties and superior deep-drawing capabilities.

Raw material preparation → pickling and rust removal → endless rolling or conventional rolling → annealing and leveling

FAQ

How to tell if steel is cold rolled?

You can tell cold-rolled steel by its smooth, shiny, scale-free surface, precise edges with sharp corners, and thinner, more dimensionally precise profiles. Cold-rolled steels are generally harder and have an oil-based coating, often with names such as "CR", SPCC, or ASTM A1008. In some cases, it may be similar in appearance to hot-rolled steel that has been pickled and oiled, but cold-rolled steel has distinctive features such as a pronounced surface finish, tighter tolerances, and increased strength (due to work hardening).

cold rolled steel sheet

WhatsApp / Tel / Wechat

Contact us via email

Still deciding? Get samples first, Contact US !

Products Category

Tag list

Cold rolled steel sheet

Steel sheet

Heat-resistant steel plate

Glossy steel plate

Inquire Now

Note: Please leave your email address, our professionals will contact you as soon as possible!

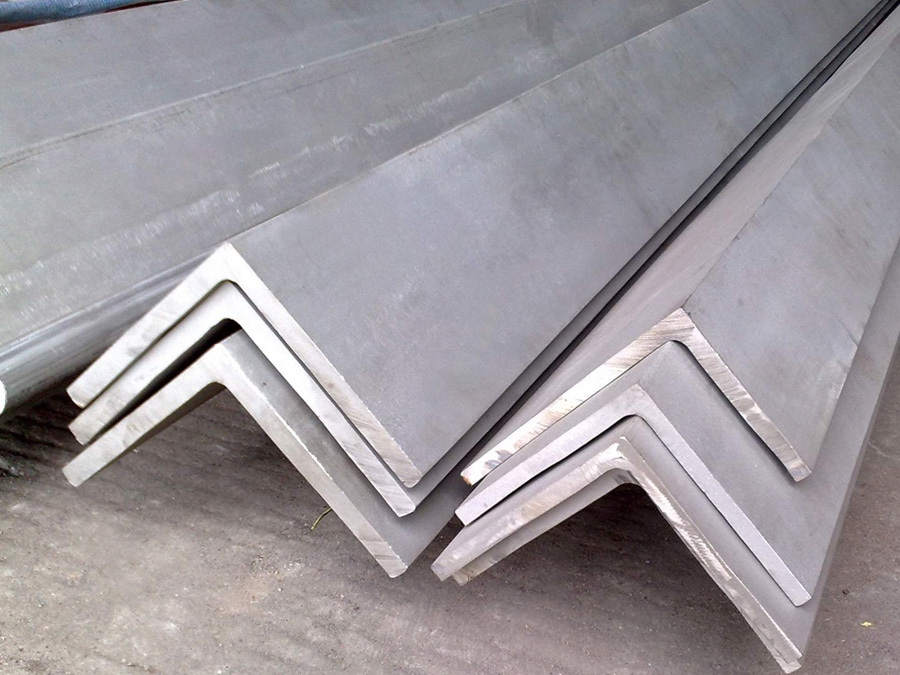

Related Products