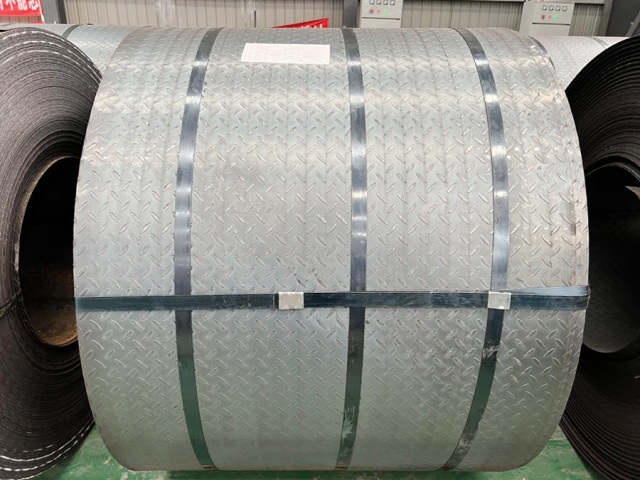

Checkered plate steel - Checkered Steel Coils

WhatsApp / Tel / Wechat

Still deciding? Get samples first, Contact US !

- Product Description

-

what is a checkered plate steel?

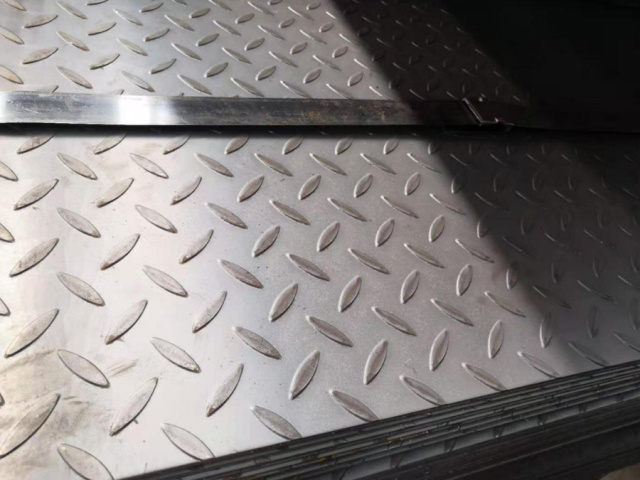

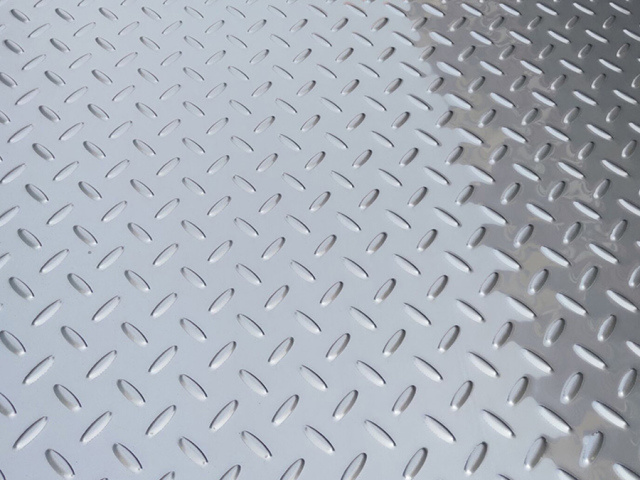

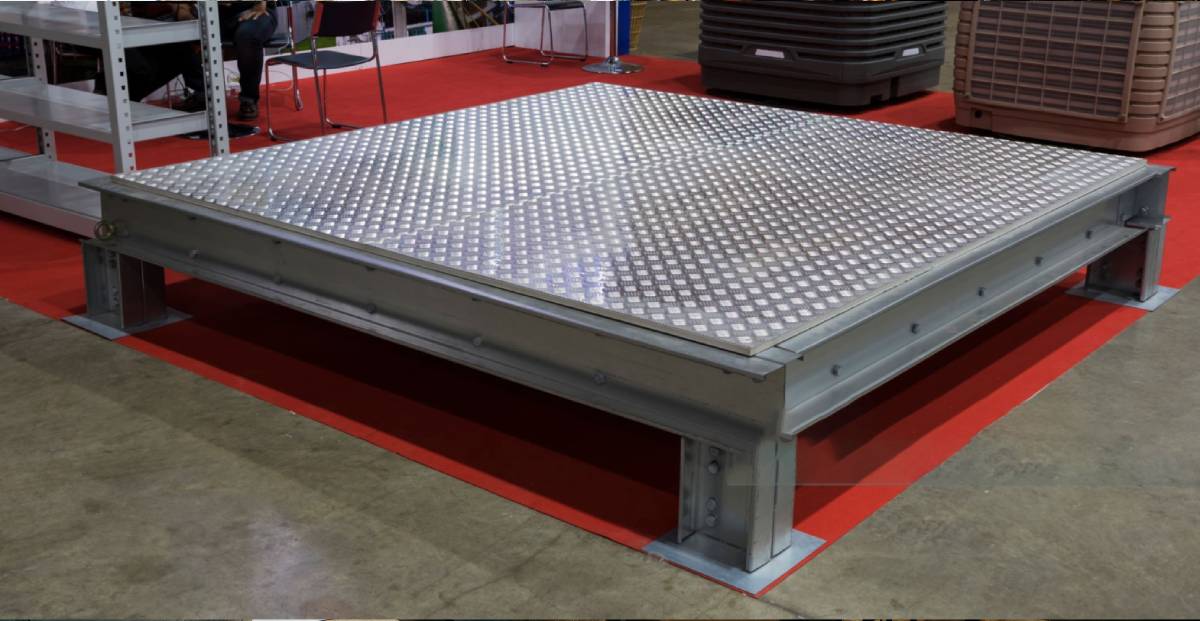

Checkered plate steel, also known as Diamond Plate, is a functional and decorative steel product that is characterized by a raised non-slip pattern (diamond/lentil/teardrop design) on the surface, which combines safety and durability. Precision pressed to create a consistent towing surface for industrial flooring, transportation equipment (truck beds/boat decks), and construction applications. The textured surface has good slip resistance in oily/wet conditions, while having the same weldability and manufacturability as a standard board. Choose from galvanized or powder-coated finishes to enhance weather resistance for outdoor use. Shineyond Group offers size customization and pattern configurations to meet specific safety requirements and aesthetic preferences in architectural, manufacturing, and marine environments.

Checkered plate steel Specifications

Material

Aluminum alloy, Ordinary steel, etc

Standard

AiSi, ASTM, DIN, GB, JIS

Length

2000~12000m

width

600~1800mm (1250/1500 for common)

Thickness

Commonly used thickness from 1.5-8mm

Weight

15-25ton/coil

MOQ

20tons

Delivery Time

21 Days

Packaging

Packing belt,binding

Application

This high-performance material is an ideal anti-slip solution for a variety of industrial and transportation applications, including factory floors, escalators, work platforms, ship decks, and vehicle floors. Its superior anti-slip properties ensure safety in wet or oily environments, and its robust construction can withstand loads of up to 5 tons per square meter. Suitable for industrial walkways, warehouse mezzanines, and pedestrian bridges, its corrosion-resistant treatment and modular design simplify installation. Its special surface texture (diamond or serrated) ensures secure support and complies with stringent OSHA/ISO 14122 safety standards, meeting the demands for durable, high-traction surfaces in the marine, automotive, and industrial sectors.

Advantages: The pattern mainly plays the role of anti-slip and decoration. The combined pattern board's anti-slip ability, bending ability, metal saving and appearance are obviously better than the single pattern board.

Checkered plate steel Process

1. Cutting: Steel plates are precisely cut to required dimensions.

2. Embossing: Patterns are pressed onto the surface for function and aesthetics.

3. Edge Rolling: Edges are smoothed to remove sharp burrs.

4. Degreasing: Oils and contaminants are cleaned off for better treatment.

5. Pickling: Acid treatment removes rust and oxides for a clean surface.

6. Coating: Protective layers are applied for corrosion resistance and appearance.

7. Curing: Coatings are dried to ensure durability and adhesion.

The patterned steel plate manufacturing process follows a precisely controlled sequence: initial hot metal undergoes desulfurization before converter smelting, hydrogen blowing, and ladle furnace refining; then thin slab continuous casting produces temperature-controlled slabs that proceed through soaking furnace heating and phosphorus removal; subsequent finishing rolling with carefully regulated parameters ensures pattern integrity during formation, followed by laminar cooling and coiling; finally, the product undergoes finishing inspection and packaging - with particular emphasis on maintaining optimal slab temperature from continuous casting through finishing rolling to prevent pattern damage and ensure product quality.

Checkered plate steel - Checkered Steel Coils

WhatsApp / Tel / Wechat

Contact us via email

Still deciding? Get samples first, Contact US !

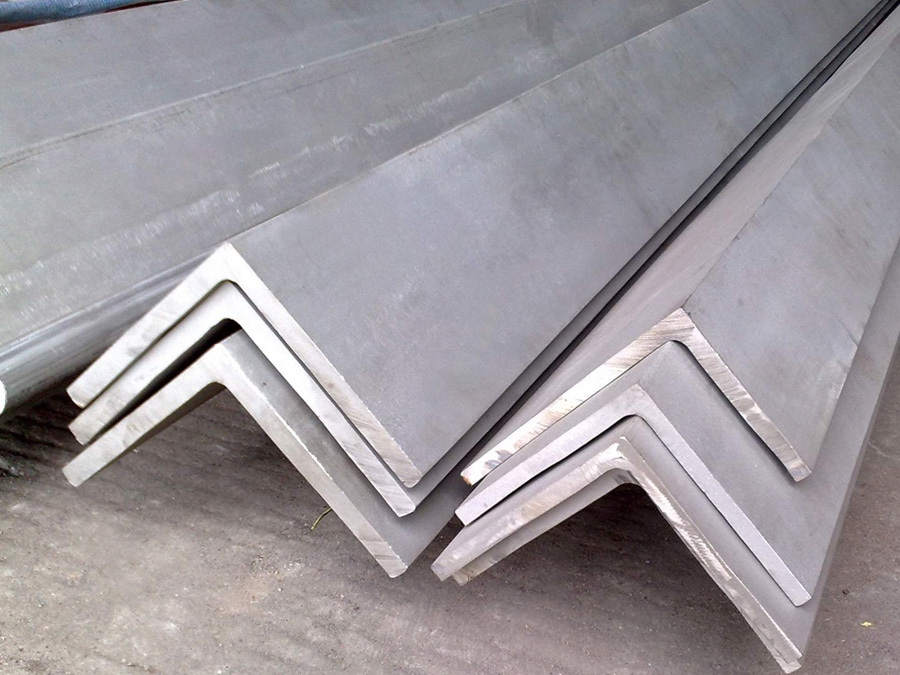

Products Category

Tag list

Mild steel checker plate/coil

Ms carbon checkered steel plate

Checkered steel coil/plate

Galvanized steel checker plate/coil

Slip resistance steel checker plate

Inquire Now

Note: Please leave your email address, our professionals will contact you as soon as possible!