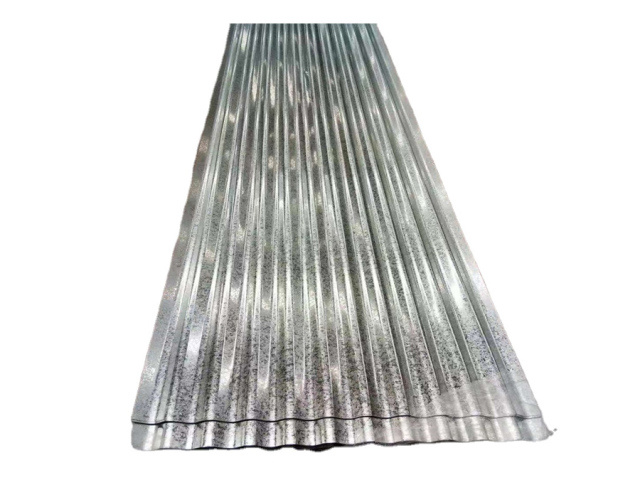

Galvanized steel roofing sheets

WhatsApp / Tel / Wechat

Still deciding? Get samples first, Contact US !

- Product Description

-

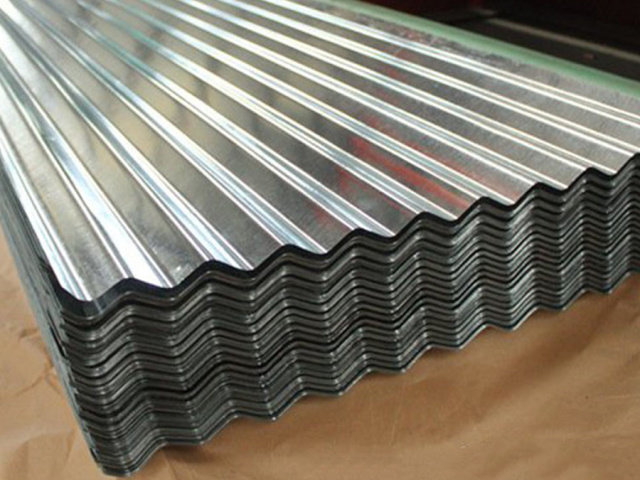

what is a Galvanized steel roofing sheet

Galvanized steel roofing panels are pressed from galvanized or aluminum-zinc coils, which can be produced into different tile shapes as needed. It is a metal roofing material that mainly uses electroplating process to form a uniform zinc layer on the surface of the steel plate, and closely combines the zinc ions with the steel substrate through electrolytic deposition technology to form a dense anti-corrosion layer.

Compared with the traditional hot-dip galvanizing process, the electro-galvanized layer is thinner (usually 3-20μm) but more evenly distributed, with the characteristics of smooth surface and high processing accuracy, which is suitable for modern building roofing systems with strict requirements for flatness.

Galvanized steel roofing panels combine the advantages of light weight (30% lighter than traditional building materials), corrosion resistance (more than 500 hours of salt spray testing) and weldability and can be applied to a wide range of colors.

The electroplated steel roofing panels provided by Shineyond Group adopt an environmentally friendly electroplating process and self-developed anti-fingerprint treatment technology, which can effectively avoid surface damage during construction, and the unit cost is reduced by 40% compared with stainless steel roofing.

Specification

Product

Standard

Grade

Zinc

Thickness

Width

Length

Package

MOQ

Delivery time

Galvanized steel roofing sheet

AISI,ASTM,GB,JIS

SGCC,SGCH,G550,DX51D,DX52D,DX53D

Z30-Z270

0.12-2.0mm

608-915mm

6meters, customized

Standard sea transport package

25MT

15-20days

Galvalume steel roofing sheet

AISI,ASTM,GB,JIS

SGCC,SGCH,G550,DX51D,DX52D,DX53D

AZ30-AZ270

0.12-2.0mm

608-915mm

6meters, customized

Standard sea transport package

25MT

15-20days

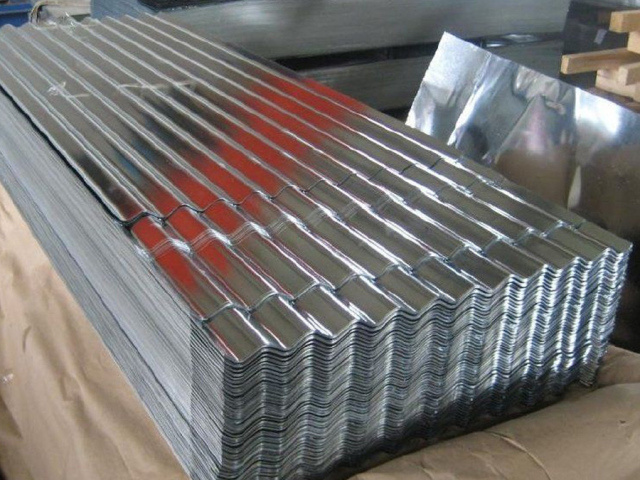

Applications

Corrugated sheets are widely used in roof panels, wall panels, floor bearing panels and ceiling panels, etc. They are also widely applied in industrial buildings such as factories and warehouses. Since the roof areas of industrial buildings are usually quite large, a kind of roof material that is sturdy, durable and relatively low in cost is needed. Galvanized corrugated sheets and aluminum-zinc coated corrugated sheets can meet these requirements, and they can be installed quickly, reducing the construction time. Meanwhile, they can also be used for some temporary buildings, such as the roofs of prefabricated houses, which are convenient for erection and dismantling.

Special craft

The formation of an alloy film of zinc and iron on the substrate of corrugated sheets in an environment of 500 °C endows galvanized corrugated sheets and aluminum-zinc coated corrugated sheets with anti-pollution properties.Galvanized/Galvalume corrugated sheets are continuously heated in an oven at 120 °C for 90 hours, and there is no obvious change in the gloss or color of the coatings. Low temperature resistance property. Galvanized/Galvalume corrugated sheets are placed at a low temperature of -54 °C for 24 hours, and there is no obvious change in the bending and impact resistance performance of the coatings. Boiling water resistance property. Samples of various corrugated sheet products are soaked in boiling water for 60 minutes, and there is no change in the surface gloss or color, nor do phenomena such as blistering, softening or swelling occur.

Advantages

Corrugated galvanized sheet is innovative, easy to install and environmentally friendly.

1.Aesthetically pleasing and flexible combinations that can express a wide range of architectural styles

2.Light weight, high strength ( strength 250~550MPa), good skin stiffness, good seismic performance of water repellent

3.Easy construction and installation, reducing installation and transport workload and shortening the construction period

4.Pressed steel sheets are environmentally friendly building materials that can be recycled, and the promotion and application of pressed steel sheets is in line with the policy of sustainable development of the national economy

P reduction Process

The substrate is processed by special corrugating machine equipment. There are a series of rolls in the equipment, and the shapes and arrangements of these rolls are customized according to the design requirements of corrugated sheets. When the substrate passes through the rolls, under the pressure of the rolls, the substrate is continuously cold-formed into wavy corrugated shapes.

According to the requirements of customers or the standard dimensions of products, the formed corrugated sheets are cut. The cutting can be carried out by using mechanical cutting equipment, such as plate shears, or by adopting numerical control cutting technology.

Galvanized steel roofing sheets

WhatsApp / Tel / Wechat

Still deciding? Get samples first, Contact US !

Products Category

Tag list

Galvanized steel roofing sheet

Zinc coated steel roofing sheet

Galvalume steel roofing sheet

Zinc-alum steel roofing sheet

GI roofing plate

GL roofing plate

Corrugated roofing sheet

Trapezoidal steel roofing plate

Steel roofing sheet antirust

Inquire Now

Note: Please leave your email address, our professionals will contact you as soon as possible!

Related Products