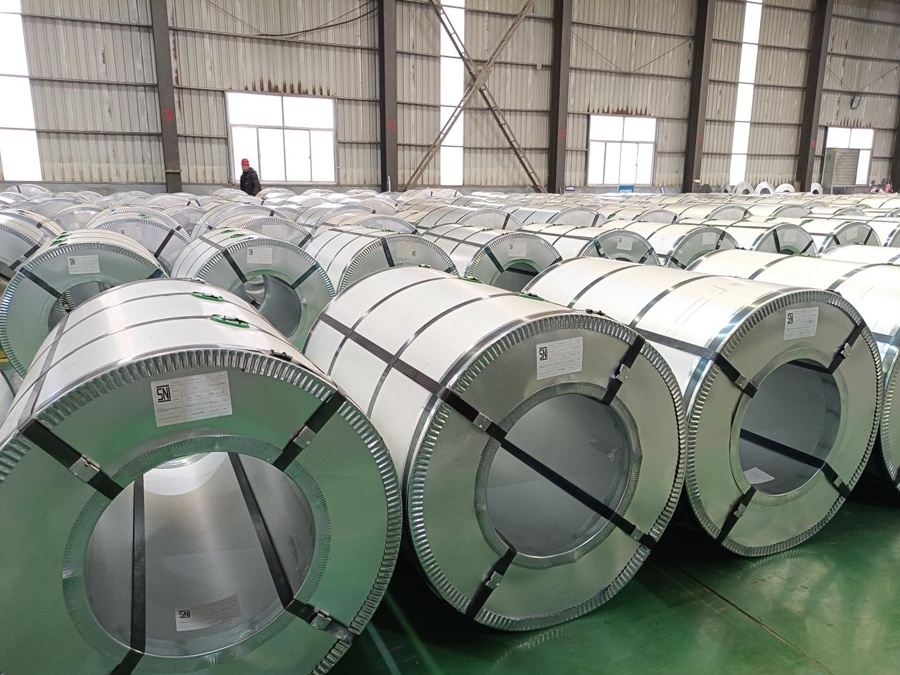

Galvalume Steel Coil

WhatsApp / Tel / Wechat

Still deciding? Get samples first, Contact US !

- Product Description

-

What is galvalume steel coil?

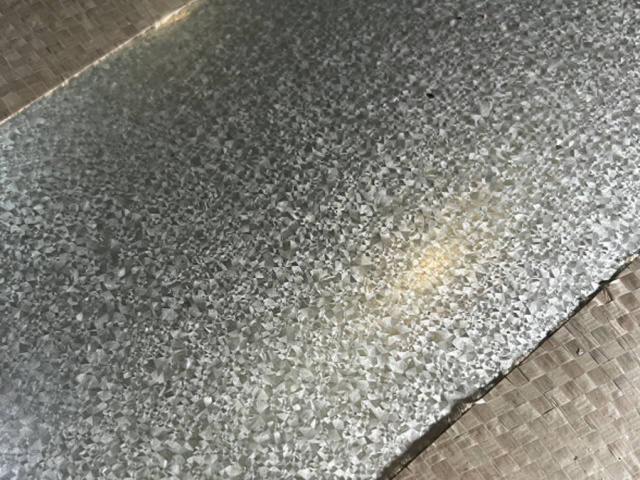

Galvalume Steel Coil is a high-quality metal composite material made by immersing a high-quality steel coil in an alloy bath composed of 55% aluminum, 43.4% zinc and 1.6% silicon at a molten state at 600°C to form a special coating with a dense tetragonal lattice structure.

It mainly combines the corrosion resistance of aluminum and the cathodic protection characteristics of zinc, and the corrosion resistance can be 2-6 times that of ordinary galvanized sheet, and has excellent high temperature stability (resistance to 315 °C), more than 80% solar radiation reflectivity and ultra-long service life.

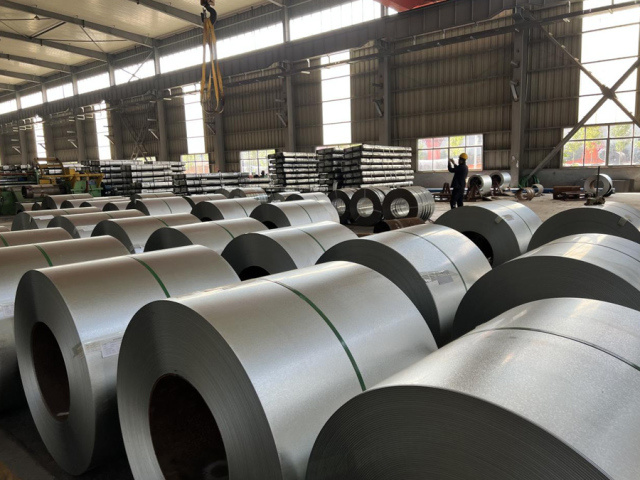

Shineyond Group Suppliers and Wholesale galvalume steel coil meet the needs of building envelope, photovoltaic bracketing, automobile manufacturing, and more

Specification

Material

Aluminium-zinc alloy

Standard

ASTM A653/A653M-99, ASTM A90/A90M, ASTM D2092, JIS SGCC, etc

Grade

DC51D AZ、DC52D AZ DC53D AZ、DC54D AZ、DC56D AZ、S250GD AZ、S350GD AZ、S550GD AZ

Thickness

0.12-2.0mm

Width

700-1250mm

Zinc Layer

30-200g/㎡

Inner Diameter

508/610mm

Coil Weight

3-6tons or according to customer requirements

Surface Treatment

oiled, passivated or chrome-free passivated, passivated + oiled

MOQ

36 tons

Delivery Time

about 35 days

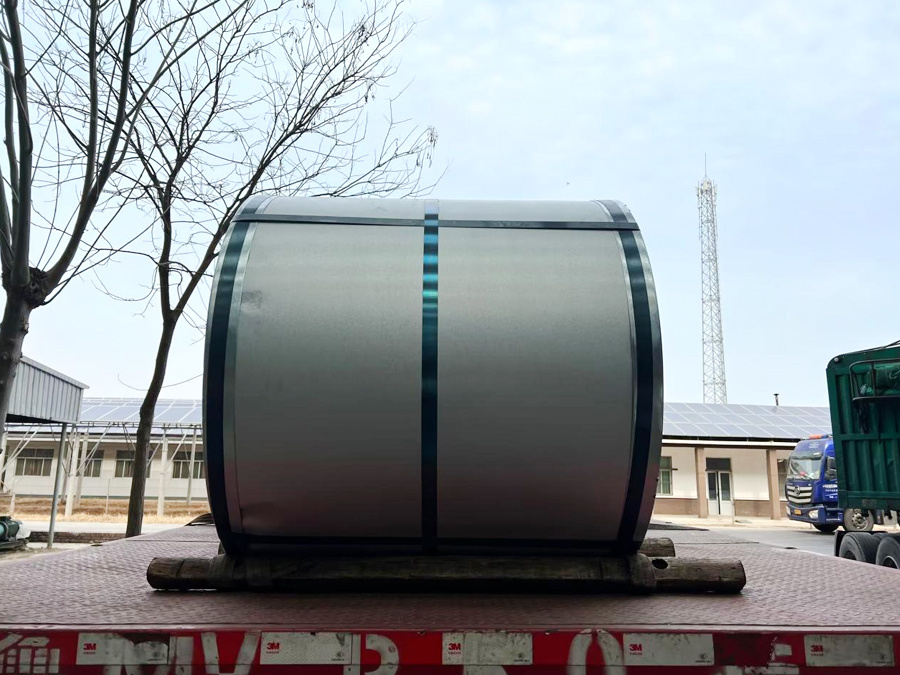

Package

Standard export package

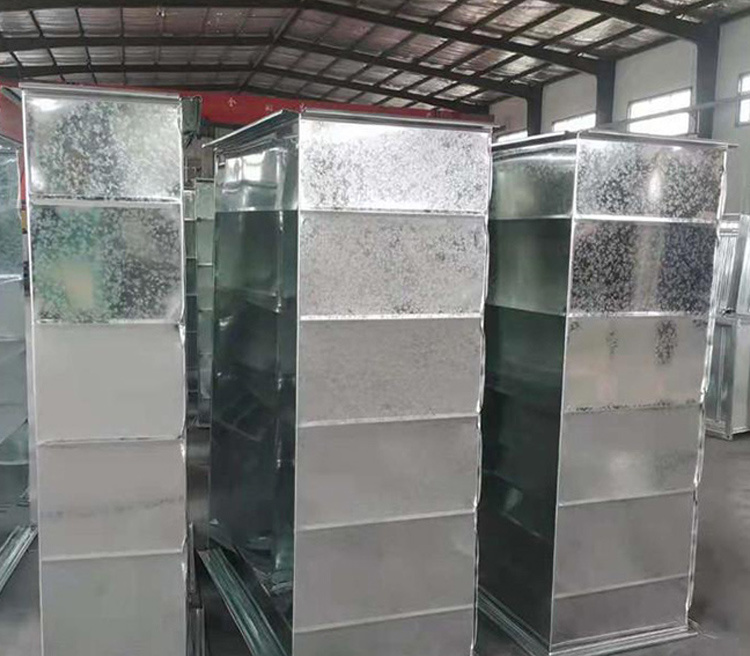

galvalume steel coil Applications

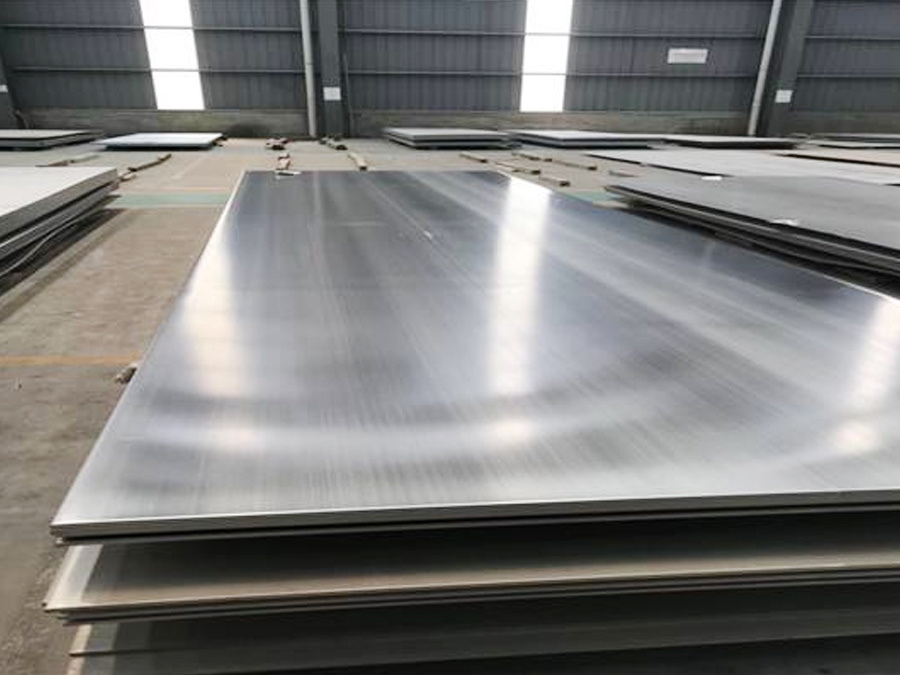

Galvalume steel coil is widely used in many fields due to their excellent anti-corrosion properties and beautiful surface:

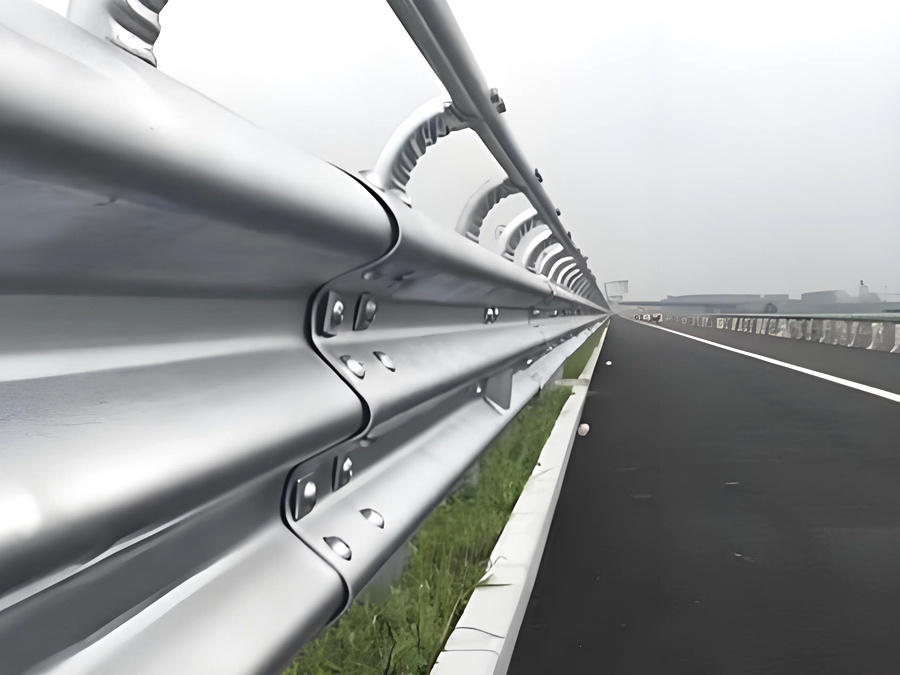

1. Construction field: used to manufacture decorative materials such as curtain walls and roofs.

2. Transportation: for vehicle shells and interior decoration.

3. Power and communication field: used for cable bracket, piping and communication tower, etc.

4. Other fields: such as high and low voltage distribution cabinets, electrical cabinets, steel plate grain silos, elevator cars and other outdoor surface parts.

Selling Points and Advantages

1. Corrosion resistance: The coating of galvalume steel coil provides excellent corrosion resistance, resulting in good durability in a wide range of environmental conditions, especially in humid, salt spray and corrosive climates.

2. High Temperature Stability: These coils are usually highly heat resistant and can be used in high temperature environments such as industrial furnaces and water heaters.

3. Coating uniformity: Galvalume steel coil is usually coated uniformly, providing an even appearance and protection.

4. Lightweight: Galvalume steel coil is lighter in comparison to pure steel coils and are therefore widely used in applications where lightweight is required.

5. Electrical Conductivity: These coils usually have good electrical conductivity and are suitable for electrical equipment and electronics.

6. Malleability: Galvalume steel coil is easy to process and shape, and are therefore commonly used for a variety of products including roofing, piping, parts and decorative materials.

7. Environmentally Friendly: The coating of galvalume steel coil is usually recyclable and environmentally friendly.

Production Process

1. Pre-treatment of steel coils

First of all, you need to uncoil, put the steel coil on the specialized machine, and then carry out pretreatment. Pre-treatment mainly includes oil removal, rust removal and other treatments to ensure that the surface of the steel coil is free of impurities, which is conducive to subsequent processing.

2. Surface treatment

Surface treatment is to make the surface of steel coils better adsorption of plating, enhance adhesion. Common surface treatment methods include physical and chemical methods. Physical methods are mainly used to increase the surface roughness by mechanical grinding, and chemical methods are mainly used to improve the surface condition by pickling, phosphatizing and other methods.

3. Aluminum zinc plating

After the surface treatment is completed, the aluminum zinc plating step can be carried out. This step is achieved by dipped in an aluminum-zinc liquid. The liquid contains metal ions such as aluminum and zinc, which are deposited on the surface of the steel coil by electrochemical reaction to form a uniform layer of aluminum-zinc plating.

4. Painting

Painting is the last manufacturing step of galvalume steel coil. This step forms a baking paint layer on the galvanized coil to protect the substrate and give the panel color and beauty, and improve the product's adhesion and corrosion resistance. Painting methods include spraying, brushing, rolling, coiling, etc. Different methods are selected according to different needs.

Galvalume Steel Coil

WhatsApp / Tel / Wechat

Still deciding? Get samples first, Contact US !

Products Category

Tag list

Galvalume steel coil

Zinc aluminium coil

Galvalume coils

Zinc-Aluminum steel coil

Pre-Painted Aluminum Zinc Plated Steel Coil

Galvalume roofing coil

Aluzinc Steel Coil

Inquire Now

Note: Please leave your email address, our professionals will contact you as soon as possible!

Related Products